ZP 20 Tablet Press Pharmaceutical

High pressing capacity of ZP-20 rotary tablet press: As an advanced pharmaceutical equipment, ZP-20 rotary tablet press has excellent production capacity. It is capable of producing large numbers of tablets per hour, but more importantly, it can handle difficult-to-file materials such as high-density powders or difficult-to-compact granules. This is thanks to its unique "down-pressure guide" technology, which increases the pressure during the pressing process and ensures the high quality and stability of the formed material.

How the "pressure-down guide" works: The core of the "pressure-down guide" technology is an improved guide rail system that enables it to exert additional vertical pressure during the pressing process. Usually, traditional guide rail systems are mainly used to guide the up and down movement of the tablet press but do not provide additional pressure. However, the "pressure-down guide" allows the guide to actively exert vertical pressure, thereby improving the compression capability during the tableting process.

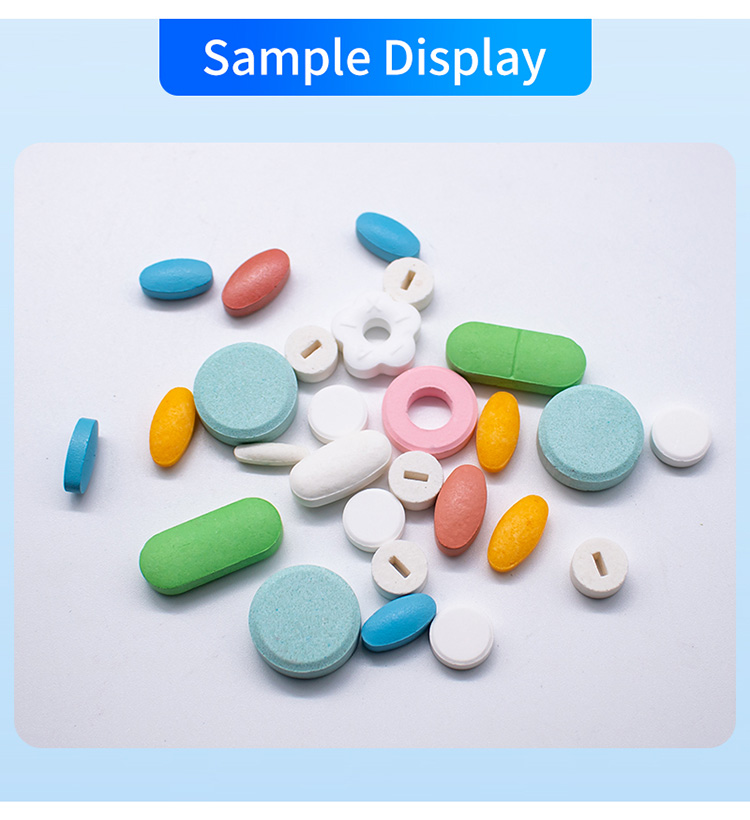

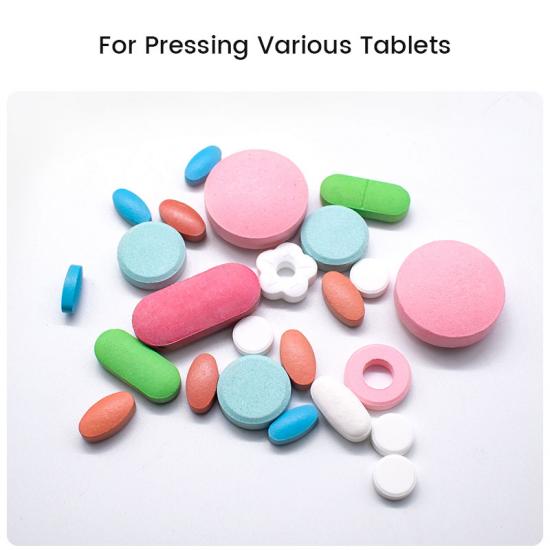

Responding to the needs of difficult-to-form materials: In the pharmaceutical industry, some materials are difficult to be pressed and formed in conventional equipment due to their special properties. These materials may have high viscosities, extremely high particle densities, or other challenging characteristics. It may be difficult to meet the production needs of these materials using traditional tablet presses. However, the introduction of "down-pressure guide rail" technology has changed this situation, allowing the ZP-20 pharma pills press to effectively handle these materials that are difficult to line.

Improve production efficiency and product quality: The application of "down-pressure guide rail" technology not only improves the production capacity of the ZP-20 automated tablet press, but also improves product quality. By applying additional vertical pressure, uniformity and consistency of the formed material are ensured. This reduces product failure rates, improves product quality, and reduces waste generation.

*** Technical parameter

|

Model |

ZP-20 Tablet Press Machine |

|

Max. Production Capacity |

40,000 pcs/h |

|

Max. Pressure |

80KN |

|

Max. Dia. of Tablet |

25mm |

IPv6 network supported

IPv6 network supported