Categories

New Blog

Tags

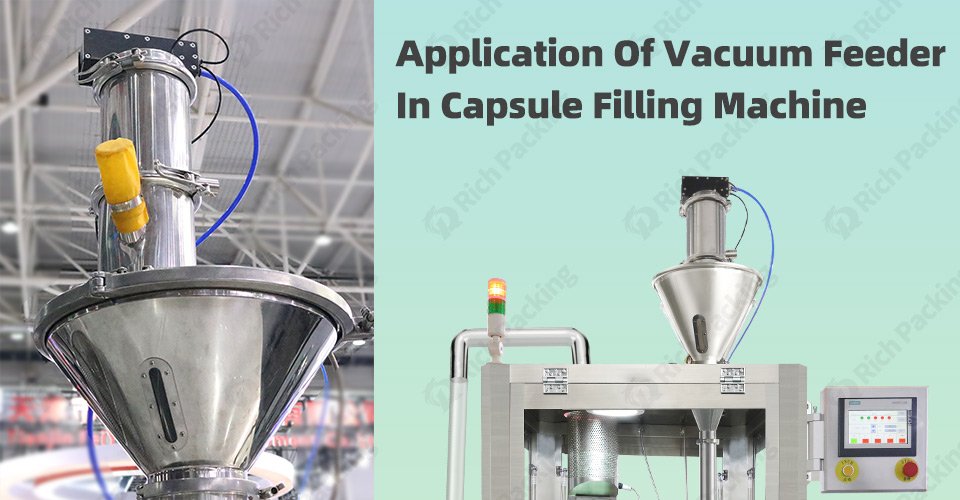

In the realm of pharmaceutical manufacturing, the precision and efficiency of production processes are paramount to ensuring the quality and safety of medications. Among these critical steps, the role of the Capsule Filling Machine stands out as a cornerstone in the production line, particularly when it comes to integrating advanced technologies like the Vacuum Feeder. This innovative integration not only streamlines the filling process but also enhances accuracy and consistency, making it a game-changer in the modern-day pharmaceutical industry. As you delve into the intricacies of how the Vacuum Feeder enhances the functionality of Capsule Filling Machines, you'll discover how this synergy revolutionizes the way we manufacture capsules.

Before delving into the specifics of the Vacuum Feeder's application, it's essential to grasp the fundamentals of the Capsule Filling Machine. This machine is designed to automate the process of filling empty capsules with powdered, granular, or liquid medications. It operates with meticulous precision, ensuring that each capsule contains the precise dosage as specified. The process typically involves several stages, including capsule orientation, separation, filling, and sealing, all of which must be executed seamlessly to maintain the integrity of the final product.

Enter the Vacuum Feeder, a device that leverages the power of suction to gently and efficiently transport materials from one location to another. By creating a vacuum, it's able to capture and hold onto fine powders, granules, or even small parts without causing damage or loss of integrity. This capability makes the Vacuum Feeder an ideal solution for pharmaceutical applications where delicacy and precision are of the utmost importance.

1. Improved Accuracy and Consistency: By integrating the Vacuum Feeder into the Capsule Filling Machine, manufacturers can significantly enhance the accuracy and consistency of the filling process. The controlled suction ensures that the exact amount of medication is delivered to each capsule, minimizing overfilling or underfilling issues.

2. Reduced Contamination Risks: The enclosed nature of the Vacuum Feeder minimizes the exposure of the medication to external contaminants, thereby safeguarding the cleanliness and purity of the final product. This is especially crucial in the pharmaceutical industry, where even trace amounts of impurities can compromise the safety and efficacy of medications.

3. Increased Efficiency and Productivity: Automation through the use of the Vacuum Feeder streamlines the filling process, reducing manual handling and labor costs. It also allows for continuous operation, significantly boosting overall production efficiency and throughput.

4. Enhanced Flexibility: The Vacuum Feeder's ability to handle a wide range of materials, from fine powders to larger granules, provides Capsule Filling Machines with unprecedented versatility. This flexibility enables manufacturers to adapt to changing product demands and formulations with ease.

Despite its numerous advantages, the integration of the Vacuum Feeder into Capsule Filling Machines also poses certain challenges, such as ensuring seamless synchronization between the two systems and maintaining optimal suction levels to prevent material loss or clogging. To overcome these hurdles, manufacturers often collaborate with experts in automation and vacuum technology to design customized solutions that cater specifically to their production needs.

In conclusion, the Application of Vacuum Feeder in Capsule Filling Machines represents a significant leap forward in the pharmaceutical manufacturing landscape. By harnessing the power of suction, this innovative technology enhances accuracy, reduces contamination risks, boosts efficiency, and adds flexibility to the filling process. As the industry continues to evolve, the synergy between the Vacuum Feeder and Capsule Filling Machine will undoubtedly play a pivotal role in shaping the future of medication production, ensuring that patients receive safe, effective, and consistently dosed medications. With this technology at the forefront, the pharmaceutical industry stands poised to meet the ever-growing demands of a global healthcare system.