Categories

New Blog

Tags

You operate in a competitive pharmaceutical market where every detail matters. Understanding the benefits and functionalities of Capsule Filling Production Equipment is crucial for boosting production efficiency and maintaining consistent quality. This guide provides a thorough overview of capsule filling production equipment, explaining its core components, technological innovations, and strategic benefits. As you read, you will learn about process optimization, quality control, automation, and integration with your overall manufacturing system. These insights will empower you to optimize your production line and achieve better results.

Capsule Filling Production Equipment comprises a series of machines and systems designed to fill hard or soft capsules with powders, pellets, or liquids. These systems ensure accurate dosing and high throughput. You use this equipment to convert active pharmaceutical ingredients (APIs) and excipients into a finished capsule product that meets strict regulatory standards. The process involves:

Understanding these processes is fundamental to optimizing your capsule production.

Efficient material handling is the first step in capsule filling. You need systems that ensure a consistent flow of powder to the filling station. Key components include:

These components are critical for avoiding blockages and ensuring consistent filling.

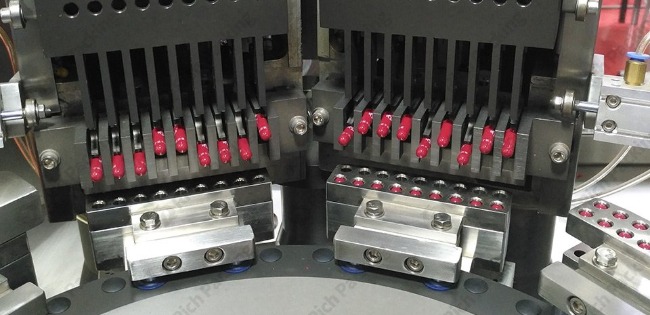

At the heart of your production line is the capsule filling machine. Modern machines are designed for high-speed, precision dosing. They come in various configurations:

Each type of machine has unique features that cater to different production volumes and product types.

Ensuring that every capsule meets quality standards is essential. You use advanced inspection systems to monitor:

Automated quality control minimizes human error and improves overall product reliability.

Modern Capsule Filling Production Equipment is integrated with computerized control systems that allow real-time monitoring and adjustments. Features include:

These systems ensure that you can optimize your production process and quickly respond to any issues.

Automation is a key driver of efficiency. Modern capsule filling systems utilize robotic arms and automated feeders to reduce manual intervention. You benefit from:

Integrating IoT sensors into your production equipment provides real-time data on machine performance. This technology allows you to:

Modern equipment is built with modularity in mind. This allows you to:

High-speed capsule filling machines significantly boost your production output. When you optimize process parameters, you can increase the number of capsules produced per hour without sacrificing quality. Efficiency gains result from:

Quality is paramount in pharmaceutical production. Advanced equipment ensures that every capsule meets strict specifications. You achieve enhanced product quality through:

Compliance with global regulatory standards is critical. Capsule Filling Production Equipment is designed to meet Good Manufacturing Practices (GMP) and FDA/EMA guidelines. Benefits include:

While the initial investment may be high, advanced capsule filling systems lead to long-term cost savings:

Economic Impact Table:

| Before Optimization | After Optimization | |

|---|---|---|

| Production Throughput | 8,000 capsules/hour | 12,000 capsules/hour |

| Material Waste | 5% | 2% |

| Downtime | 10% of production time | 4% of production time |

| Unit Production Cost | $0.12 per capsule |

This table illustrates how advanced equipment can drive significant economic benefits.

Modern capsule filling equipment is highly flexible:

Flexibility ensures that you can respond quickly to market demands and evolving product requirements.

Understanding your production process in detail is essential to optimizing output. Here is an overview of the key stages:

Process Flow Diagram (Example):

| Key Operations | Output | |

|---|---|---|

| Material Preparation | Blending, granulation, sieving | Uniform powder blend |

| Capsule Filling | Automated feeding, filling, sealing | Accurately filled capsules |

| Quality Control | Inline inspection, weight and integrity checks |

This process flow diagram provides you with a clear view of each stage in capsule filling production.

Each step is critical to maintaining high output while ensuring that every capsule meets stringent quality standards.

Even with advanced equipment, you may encounter challenges. Understanding these issues and implementing solutions is key to optimizing your process.

Issue: Inconsistent powder flow can lead to uneven capsule filling. Solution: Implement high-quality feeders and ensure regular cleaning of material delivery systems. Monitor flow properties using IoT sensors.

Issue: Variability in fill weight can affect product quality. Solution: Calibrate filling machines regularly, and use automated weighing systems for real-time adjustments.

Issue: Unplanned downtime can disrupt production. Solution: Utilize predictive maintenance systems integrated with IoT to schedule maintenance proactively and reduce unexpected stoppages.

Issue: Meeting stringent regulatory requirements can be challenging. Solution: Invest in automated quality control and comprehensive data logging to ensure every production step is documented and compliant.

Comparison Table: Challenges vs Solutions

| Impact | Proposed Solution | |

|---|---|---|

| Material Flow Disruptions | Uneven filling, inconsistent dosing | High-quality feeders, IoT monitoring, regular cleaning |

| Dosing Variability | Inconsistent product quality | Regular calibration, automated weighing systems |

| Machine Downtime | Reduced throughput, increased costs | Predictive maintenance, IoT sensors, scheduled maintenance |

| Regulatory Compliance | Risk of recalls, non-compliance fines |

By addressing these challenges, you ensure that your production process remains efficient, compliant, and cost-effective.

Staying ahead of technological advancements will keep your production line competitive. Here are some emerging trends you should consider:

These trends will help you further optimize your production line, enhance product quality, and reduce environmental impact.

To ensure that you are getting the most from your Capsule Filling Production Equipment, follow these best practices:

Following these practices will help you achieve high output, consistent quality, and improved efficiency in your capsule filling operations.

Your Capsule Filling Production Equipment is part of a larger ecosystem. For optimal results, integrate your capsule filling process with other production stages and your supply chain:

As you target the European and American markets, ensure that your production processes meet international regulatory standards. Emphasize quality, reliability, and efficiency in your marketing communications to appeal to pharmaceutical companies, packaging enterprises, and distributors.

Supply Chain Integration Table:

| Key Considerations | Benefits | |

|---|---|---|

| Upstream (Material Sourcing) | Consistent quality, reliable supply, supplier collaboration | Reduced variability, lower production disruptions |

| Downstream (Packaging) | Automated systems, robust logistics, quality control | Faster market delivery, enhanced product integrity |

| Global Market Strategy | Regulatory compliance, quality assurance, sustainability |

This table provides a snapshot of how integrating your capsule filling process with the broader supply chain can lead to improved efficiency and market competitiveness.

Investing in advanced Capsule Filling Production Equipment can yield significant long-term savings. Consider the economic benefits:

By increasing production throughput and ensuring consistent quality, you reduce costs associated with recalls, rework, and regulatory non-compliance. The improved efficiency and product quality result in higher customer satisfaction and market share, ultimately leading to a positive ROI.

Economic Impact Table:

| Before Investment | After Investment | |

|---|---|---|

| Production Throughput | 8,000 capsules/hour | 12,000 capsules/hour |

| Material Waste | 5% | 2% |

| Labor Cost | High (manual intervention required) | Lower (automation-driven) |

| Energy Consumption | 10 kWh per cycle | 7 kWh per cycle |

| ROI | Moderate |

This table highlights the economic advantages of investing in modern capsule filling equipment.

Staying ahead of technological advancements is critical for your long-term success in capsule production. Here are some future trends:

Embracing these trends will help you maintain a competitive edge and continuously improve your production processes.

Understanding and optimizing your Capsule Filling Production Equipment is crucial to boosting production efficiency, ensuring consistent quality, and reducing costs. By leveraging advanced technology, automation, and data-driven insights, you can transform your production line and achieve significant economic benefits. For further inquiries or personalized consultation, please contact us today.