Categories

New Blog

Tags

A blister packaging machine is an essential piece of equipment for the packaging of various products, especially in the cosmetics industry. Whether it's for lotions, creams, or makeup products, blister packaging provides an efficient, reliable, and protective way to store and distribute cosmetic items. In this article, we’ll explore the process, benefits, and best practices of using a blister packaging machine for cosmetics, helping you understand how this technology enhances both the packaging and consumer experience.

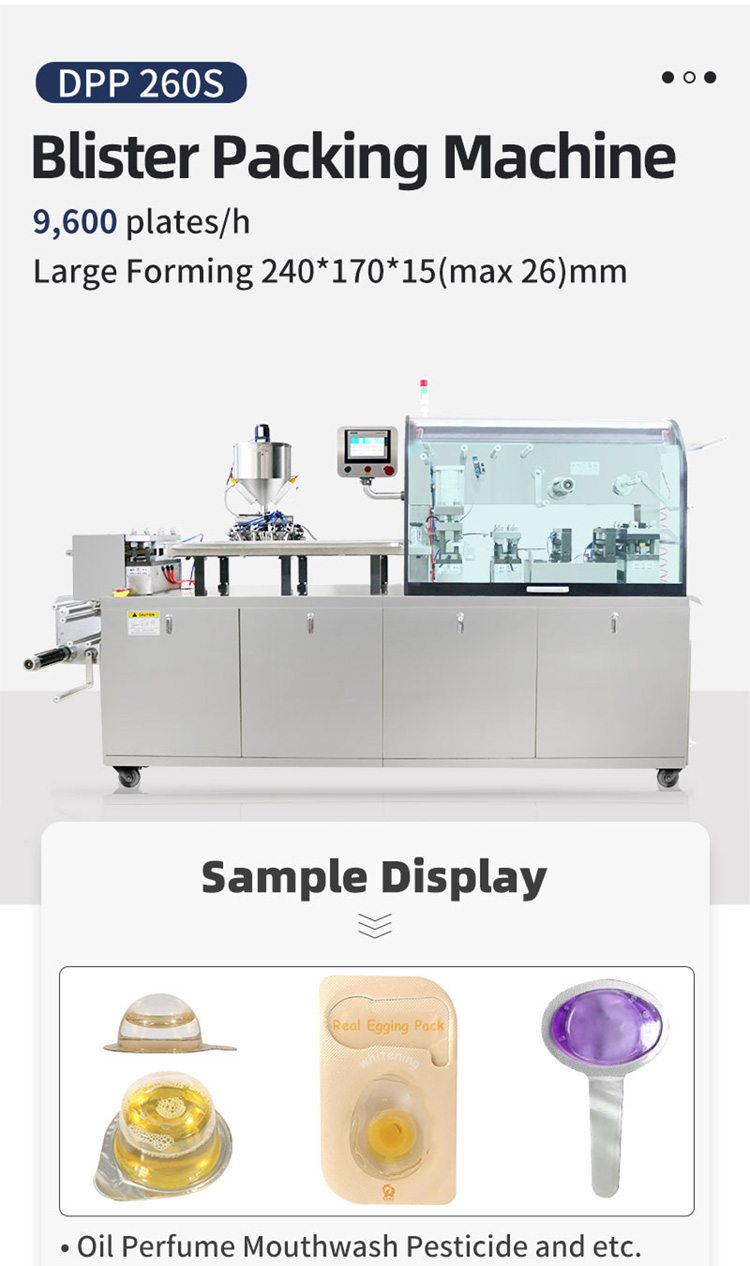

A blister packaging machine is a device used to create a pre-formed plastic cavity, known as a blister, which is sealed around the product to secure it for storage and transportation. The machine typically heats a sheet of plastic, molds it into a shape that matches the product, fills the cavity with the item, and then seals it using a foil or paper backing. This method ensures that the product is protected from external elements like moisture, air, and contamination.

1. Heating: The plastic is heated until it becomes pliable.

2. Forming: The heated plastic is molded into a cavity using a die or vacuum.

3. Filling: The cosmetic product is inserted into the cavity.

4. Sealing: A foil or paper backing is applied and sealed to keep the product safe.

This process ensures that the product is secure, tamper-proof, and ready for distribution.

One of the primary reasons why cosmetics companies use blister packaging is for the protection it provides. Blister packs protect products from external damage, contamination, and exposure to light, moisture, or air that could degrade the product.

For instance, products like creams, serums, and makeup can be susceptible to spoilage if not stored properly. By using a blister packaging machine, the items are shielded from these environmental factors, helping preserve their quality.

Blister packs are often tamper-evident, making it easy for consumers to see if a product has been opened. This is particularly important in the cosmetics industry, where product integrity and consumer trust are paramount.

Blister packaging allows for visually appealing, customized designs that align with brand identity. Brands can include logos, colors, and other design elements, creating an attractive and professional look that stands out on retail shelves.

Blister packaging is compact and easy to carry, which is particularly beneficial for consumers on the go. The packaging makes it easy for customers to access individual doses of the product, ensuring they use the correct amount without wasting any.

Using a blister packaging machine for cosmetics can help reduce costs associated with packaging materials and labor. The automation of the packaging process reduces the need for manual labor, improving overall efficiency. Furthermore, the process minimizes waste, helping brands save money on raw materials.

Blister packaging machines are designed for high-speed production, which is crucial for large-scale cosmetic manufacturers. The ability to package a high volume of products in a short time allows businesses to meet increasing consumer demand and improve profitability.

A blister packaging machine ensures uniformity in packaging, reducing the risk of human error. With automated processes, each blister pack is sealed tightly, ensuring the same level of protection and precision across batches.

Blister packaging machines can handle a variety of cosmetic products, from small tubes of lotion to single-use makeup wipes. The flexibility to customize cavity sizes and shapes ensures that each product is packaged according to its specific needs.

|

Benefit |

Description |

|

Cost-Effectiveness |

Automation reduces labor costs and material waste |

|

Speed and Efficiency |

High-speed production for large-scale manufacturing |

|

Consistency and Quality |

Automated process ensures uniform packaging quality |

|

Flexibility |

Customizable cavity sizes for different product types |

Blister packaging is particularly popular for single-use skincare products like face masks or facial serums. These products are often packaged individually to maintain their effectiveness and convenience. The blister packaging machine provides a cost-effective solution for such items.

Blister packs are ideal for cosmetics samples, as they offer portability and ensure product integrity. Sample packs for moisturizers, lipsticks, or other products are typically sealed in blister packaging for hygiene and convenience.

Cosmetic creams and lotions benefit from blister packaging, especially in smaller, travel-friendly sizes. The seal provides protection against contamination and ensures the product remains fresh.

Certain cosmetic supplements come in the form of tablets or capsules, and blister packs provide an effective and efficient way to package them for consumer use.

A blister pack provides a barrier that helps keep the product in optimal condition throughout its lifecycle, from production to the end consumer. This is especially important for products that can degrade or lose their potency when exposed to air or moisture.

By preventing exposure to environmental factors, blister packs extend the shelf life of cosmetic products. This ensures that the products remain fresh and effective until they reach the consumer.

Blister packaging provides clear, visible packaging that can display important information such as expiration dates, ingredients, and batch numbers. This transparency helps foster consumer confidence in the product.

Customization is a key advantage of using a blister packaging machine for cosmetics. Here are some ways you can customize the packaging to better suit your brand and product needs:

Blister packs come in various sizes and shapes to accommodate different cosmetic products. Whether you need single-dose packs or larger multi-use packaging, customization options are available to suit your specific product.

You can choose from a variety of materials for blister packaging, including PVC, aluminum, and other protective films. This ensures the packaging is durable and provides the necessary protection for your products.

Customized blister packaging can include your brand’s logo, colors, and design elements. This not only makes the product more attractive but also helps build brand recognition in the marketplace.

Blister packaging machines offer numerous benefits to the cosmetics industry, including enhanced protection, convenience, and cost efficiency. The customization options available make it a perfect fit for a wide variety of cosmetic products, from skincare to supplements. By adopting blister packaging, you can improve product integrity, extend shelf life, and enhance your brand’s appeal.

Need help with choosing the right blister packaging solution for your cosmetics? Reach out to us today for more information and expert guidance on finding the perfect packaging solution for your products!