Categories

New Blog

Tags

The tablet press is a cornerstone of pharmaceutical manufacturing, responsible for transforming powder or granules into solid, uniform tablets. However, achieving precise and consistent finished products requires more than just basic machine operation. It demands attention to detail, the right settings, and effective troubleshooting.

This article is a comprehensive guide to improving the precision of finished products on a tablet press. If you're looking to optimize production, reduce errors, and ensure product uniformity, this is the ultimate resource tailored to your needs.

Precision in tablet press operations is essential for meeting pharmaceutical standards and maintaining the efficacy of your tablets. Whether you’re manufacturing medication, supplements, or nutraceuticals, uniformity in weight, hardness, and size ensures the product is both effective and compliant with regulatory guidelines.

· Regulatory Compliance: Deviations in weight or dosage can lead to regulatory penalties.

· Patient Safety: Accurate dosing ensures medication effectiveness and prevents overdosing or underdosing.

· Cost Efficiency: Fewer rejected products result in less waste and lower operational costs.

To improve precision, you first need to understand the factors that influence tablet quality. These include:

The uniform flow of powder into the die cavity is critical for consistent weight and density. Powders with poor flow characteristics can result in uneven tablets.

The force applied during compression directly impacts tablet hardness and weight. Improper force settings can lead to defects such as capping or lamination.

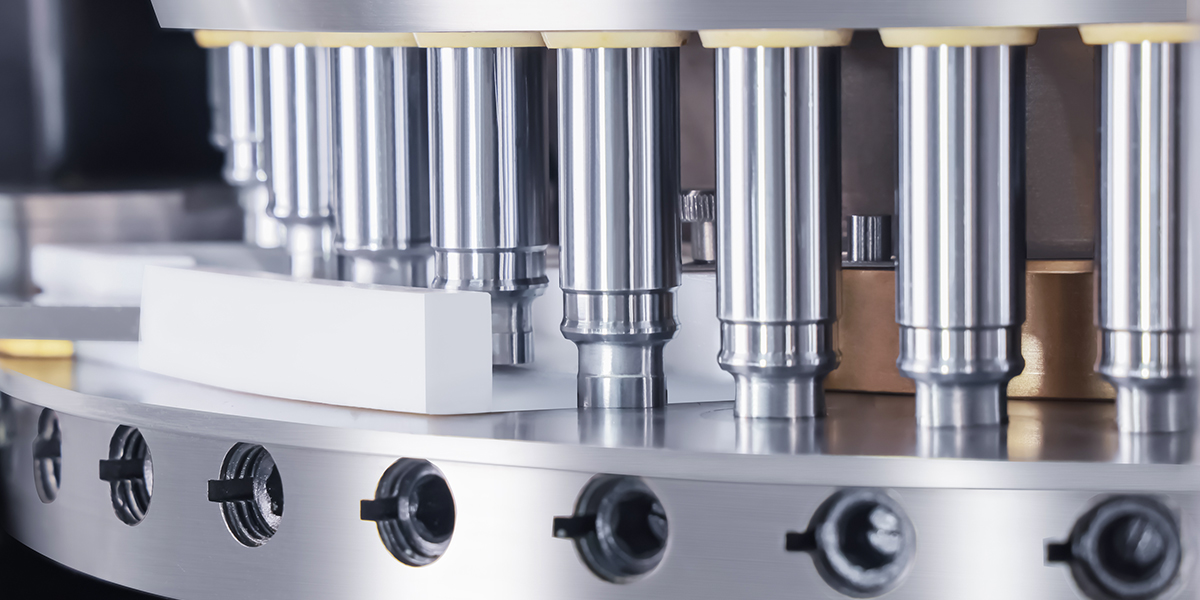

Worn or misaligned punches and dies can compromise tablet uniformity. Regular inspection and maintenance are crucial to ensure precision.

A poorly calibrated tablet press will produce inconsistent results. Regular calibration ensures the machine operates within set parameters.

The flowability of your powder blend is one of the most critical factors in achieving uniform tablets.

· Granulation: Use wet or dry granulation methods to improve flow properties and achieve uniform particle size.

· Additives: Incorporate flow-enhancing excipients such as magnesium stearate or colloidal silicon dioxide.

Compression force must be consistent to ensure uniformity in weight and hardness.

· Adjust Settings: Use the machine’s control panel to fine-tune compression force based on product requirements.

· Real-Time Monitoring: Invest in a tablet press with built-in sensors for real-time force monitoring.

Regular maintenance of dies and punches ensures precise compression and ejection.

· Inspection: Check for wear, corrosion, or damage regularly.

· Lubrication: Apply appropriate lubricants to reduce friction and wear.

Even with optimal settings, challenges can arise. Here’s how to troubleshoot some common issues:

Cause: Uneven powder flow or inconsistent fill depth.

Solution: Adjust feeder settings and ensure uniform powder blending.

Cause: Insufficient compression force or over-dry granules.

Solution: Increase compression force and optimize granulation moisture levels.

Cause: Poor tablet release due to sticky ingredients.

Solution: Use anti-adherents like talc or magnesium stearate.

|

Problem |

Cause |

Solution |

|

Weight Variations |

Uneven powder flow |

Adjust feeder and blending process |

|

Capping and Lamination |

Insufficient compression force |

Increase compression force |

|

Sticking and Picking |

Sticky granules or poor lubrication |

Add anti-adherents |

Modern tablet presses come with advanced features that make precision easier to achieve.

High-tech tablet presses are equipped with sensors that monitor critical parameters, such as compression force and fill depth, in real-time.

Machines with automatic calibration eliminate the need for manual adjustments, ensuring consistent performance.

Some tablet presses can produce multi-layer tablets with precise control over each layer, expanding product possibilities.

Precise settings lead to uniform tablets, ensuring consistent efficacy and consumer trust.

Fewer rejected tablets mean lower production costs and less material wastage.

Efficient settings and processes allow for higher throughput without compromising quality.

Meeting strict pharmaceutical standards ensures smoother audits and regulatory approvals.

For manufacturers aiming to improve precision and efficiency, the HZP-26D-40D Rotary Tablet Press Machine by Rich Packing is a cutting-edge solution.

· Real-Time Monitoring: Integrated sensors track compression force and fill depth for consistent tablet quality.

· High-Speed Production: Capable of producing up to 260,000 tablets per hour, ensuring efficiency.

· Durable Build: Constructed with GMP-compliant materials for long-lasting reliability.

· User-Friendly Interface: An intuitive control panel simplifies adjustments and monitoring.

|

Feature |

Benefit |

|

Real-Time Monitoring |

Ensures consistent tablet quality |

|

High-Speed Production |

Meets large-scale production demands |

|

Durable Build |

Minimizes maintenance requirements |

|

User-Friendly Interface |

Reduces operator error |

A well-trained operator can identify issues early and maintain optimal machine performance.

Routine maintenance prevents downtime and ensures consistent results.

Keep detailed records of machine settings and batch performance to identify trends and areas for improvement.

Consider upgrading to advanced tablet presses, such as Jinlu Packing’s HZP-26D-40D, for better precision and efficiency.

Improving the precision of a tablet press requires attention to powder properties, compression force, and machine maintenance. By adopting advanced technology and best practices, you can achieve consistent, high-quality tablets while reducing costs and errors. Want to enhance your tablet press operations? Contact us today for tailored solutions!