Categories

New Blog

Tags

Blister packing machines are essential for industries like pharmaceuticals, food, and cosmetics. They ensure efficient packaging by sealing products in pre-formed cavities, offering protection and a professional appearance. However, proper installation and maintenance are crucial for optimal performance and longevity. This guide will walk you through the installation process and best maintenance practices, ensuring your blister packing machine operates efficiently and reliably.

1. Why Proper Installation and Maintenance Matter

Installing and maintaining your blister packing machine properly ensures:

· Efficiency: Optimal setup minimizes downtime and maximizes productivity.

· Longevity: Regular maintenance prevents wear and tear, extending the machine's life.

· Product Quality: Accurate installation and consistent maintenance ensure high-quality packaging and reduce defects.

· Regulatory Compliance: Well-maintained machines meet industry standards and pass inspections effortlessly.

Installing a blister packing machine involves careful planning and execution. Below are the key steps:

· Space Requirements: Ensure the site has sufficient room for the machine and operator movement.

· Electrical Setup: Verify voltage compatibility with the machine’s specifications. Install proper wiring and circuit protection.

· Air Supply: Blister packing machines often require compressed air. Install an air compressor with adequate pressure and capacity.

· Environmental Conditions: Maintain a clean, dust-free environment with controlled temperature and humidity.

· Follow the manufacturer’s assembly instructions.

· Securely fix components like the forming station, sealing unit, and cutting station.

· Connect auxiliary systems, such as the vacuum pump and compressed air supply.

· Calibration: Check alignment of forming and sealing stations.

· Trial Run: Run the machine without load to ensure all components are functioning correctly.

· Inspection: Examine moving parts, such as rollers and chains, for smooth operation.

Routine maintenance is essential for keeping your blister packing machine in peak condition. Below are key maintenance activities:

· Cleaning: Remove dust and residue from the forming and sealing stations. Use non-abrasive cleaning agents.

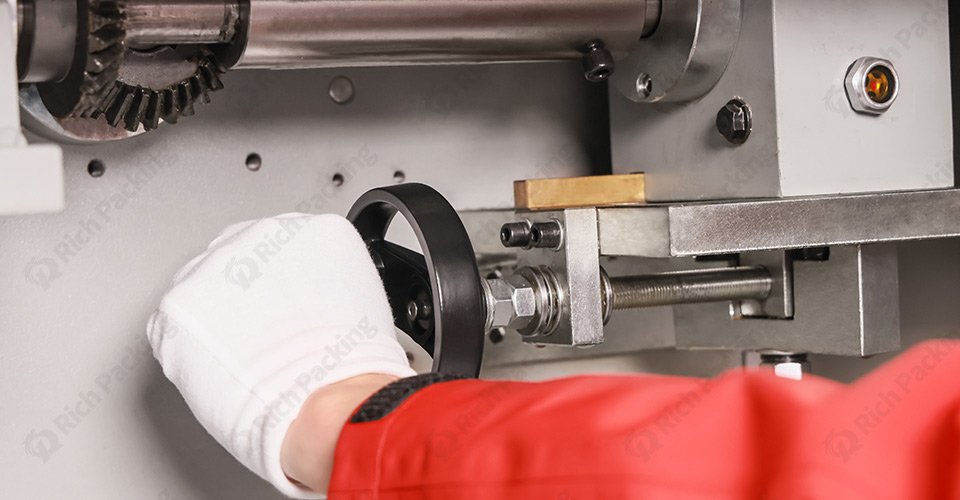

· Lubrication: Apply lubricant to moving parts, such as rollers and bearings, to reduce friction.

· Inspection: Check for loose bolts, wear on belts, and proper alignment of components.

· Check Electrical Systems: Inspect wiring, switches, and connections for wear or damage.

· Inspect Air Supply: Clean air filters and ensure consistent pressure.

· Test Sensors: Verify that temperature and pressure sensors are calibrated correctly.

· Alignment Checks: Ensure proper alignment of forming, sealing, and cutting stations to avoid packaging defects.

· Replace Worn Parts: Inspect and replace components such as heating elements, gaskets, and seals as needed.

· System Calibration: Perform a complete calibration to maintain accuracy in forming and sealing.

Even with regular maintenance, issues can arise. Here’s how to address common problems:

|

Problem |

Cause |

Solution |

|

Uneven Sealing |

Misalignment of sealing station |

Realign the sealing station; check rollers. |

|

Material Jamming |

Incorrect material tension or feed rate |

Adjust tension and feed settings. |

|

Poor Forming Quality |

Insufficient heating or air pressure |

Increase heating temperature or air pressure. |

|

Machine Vibration |

Loose components or worn parts |

Tighten bolts and replace worn components. |

For long-term reliability, incorporate these advanced maintenance strategies:

· Use sensors to monitor machine performance in real-time.

· Analyze data to predict potential failures and address them proactively.

· Keep an inventory of spare parts like belts, seals, and bearings to minimize downtime.

· Train operators to identify early signs of wear or malfunction.

· Regularly update training to include new technologies or machine upgrades.

· Plan for a complete machine overhaul every 12-18 months, depending on usage intensity.

· Include detailed inspections of all components and replacement of critical parts.

Modern blister packing machines offer various upgrades to improve performance:

· Add automated feeding systems to enhance speed and reduce manual labor.

· Integrate monitoring systems for real-time performance tracking.

· Upgrade to energy-efficient heating systems and motors to reduce operating costs.

· Incorporate custom sealing patterns or advanced cutting tools for specialized packaging.

For complex machines, partnering with a professional service provider can be beneficial:

· Expert Technicians: Trained technicians can handle intricate repairs and adjustments.

· Emergency Support: Quick response times minimize downtime during unexpected failures.

· Regular Audits: Scheduled visits ensure the machine is always in optimal condition.

Installing and maintaining a blister packing machine requires meticulous attention to detail and a proactive approach. By following the steps outlined in this guide, you can ensure efficient operation, minimize downtime, and extend the life of your equipment. Regular maintenance, operator training, and strategic upgrades will help you achieve consistent, high-quality packaging and meet the demands of your industry with confidence.