Categories

New Blog

Tags

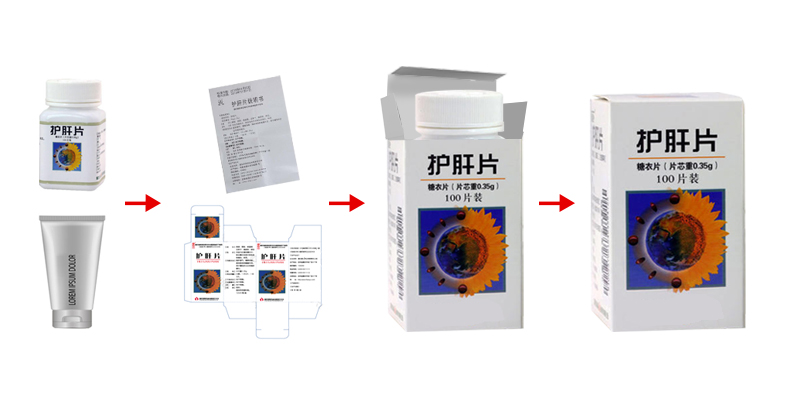

When you're managing high-demand packaging operations, precision and speed are essential. High-speed automatic cartoning machines offer the perfect solution, combining efficiency, versatility, and reliability. These machines are designed to meet the rigorous needs of industries like pharmaceuticals, food, and cosmetics. If you're looking to improve productivity while ensuring consistent quality, this is the equipment you need. Let's explore the key features that make these machines an indispensable asset for your production line.

High-Speed Performance for Increased Productivity

High-Speed Performance for Increased Productivity

The core advantage of high-speed automatic cartoning machines lies in their ability to significantly boost production efficiency.

With speeds reaching up to 300 cartons per minute, these machines are ideal for large-scale operations. Whether you're handling pharmaceuticals or fast-moving consumer goods, this level of output ensures you can meet tight deadlines without compromising on quality.

Continuous production is essential for maintaining your workflow. High-speed automatic cartoning machines are engineered to minimize downtime, offering smooth mechanics and reliable performance. Their compatibility with upstream and downstream automation systems ensures a seamless end-to-end process.

Versatile Carton Size Compatibility

One of the standout features is their ability to handle a wide range of carton sizes and formats, giving you flexibility for different product lines.

These machines can easily adjust to accommodate various carton dimensions, making them suitable for diverse industries. Whether you're packaging blister packs, bottles, or trays, this versatility is a major advantage.

Downtime during product changeovers can be a significant bottleneck. High-speed cartoning machines simplify this process with intuitive adjustments, allowing you to switch between carton sizes or styles with minimal effort. This feature is particularly valuable if your production involves multiple product variations.

Accurate and efficient product feeding is critical for maintaining a streamlined packaging process.

These machines are equipped with automated feeding systems that ensure every item is securely placed in its carton. Whether you're dealing with fragile blister packs or glass vials, the gentle yet precise handling protects your products during the packaging process.

The adaptability of the feeding systems means you can package a wide variety of items, from pouches to bottles. This flexibility allows you to cater to diverse market demands without requiring additional equipment.

The way your cartons are sealed speaks volumes about your brand's professionalism and commitment to quality.

High-speed cartoning machines offer both tuck-in and glue sealing methods, giving you the flexibility to choose based on your product and branding requirements. Glue sealing, for instance, provides a tamper-proof finish, while tuck-in closures are ideal for products that require easy opening.

Carton alignment and sealing accuracy are guaranteed, ensuring a polished and professional final product. Misalignments or weak seals can lead to customer dissatisfaction, but with these machines, you can maintain consistent quality.

Automation is only as good as the control systems that support it. High-speed cartoning machines feature intelligent technology to simplify operations and enhance accuracy.

Operating these machines is straightforward, thanks to intuitive touch screens. Multi-language support ensures that your team can easily navigate the controls, regardless of their background.

Integrated sensors monitor every step of the process, detecting issues like misfeeds, jams, or open cartons. When an error occurs, the machine automatically halts and triggers an alarm, allowing for immediate troubleshooting. This feature minimizes waste and ensures consistent product quality.

If you're operating in industries like pharmaceuticals or food, meeting stringent regulatory requirements is non-negotiable.

High-speed cartoning machines are built to comply with Good Manufacturing Practices (GMP) and FDA regulations, ensuring hygiene and safety for your products.

Sustainability Focus

Many machines are designed with energy efficiency in mind and can handle recyclable materials, helping you align with environmental goals.

The physical design of a high-speed cartoning machine is as important as its technical capabilities.

These machines feature a compact footprint, making them ideal for facilities with limited space. Despite their smaller size, they don't compromise on performance or features.

Built with high-quality materials, these machines are designed for long-term use. Their robust construction minimizes maintenance needs, reducing overall operational costs.

Every business has unique needs, and high-speed cartoning machines are equipped to accommodate them.

From specialized feeders to custom sealing mechanisms, these machines can be adapted to meet your specific requirements.

Personalization options allow you to add branding elements, such as logos or custom labels, directly during the packaging process. This enhances your product’s market appeal.

Investing in a high-speed automatic cartoning machine transforms your production process by increasing efficiency, improving packaging quality, and ensuring compliance with industry standards. Whether you’re scaling up production or diversifying your product range, these machines offer the reliability and flexibility you need to stay competitive. Embrace the benefits of advanced automation, and let your business achieve new heights of success.