Categories

New Blog

Tags

Choosing the right blister packaging machine is crucial for industries such as pharmaceuticals and consumer goods. Not only does it affect productivity, but it's also about product protection and compliance. If not selected properly, it may lead to increased production costs, packaging non-compliance and other problems. Therefore, how to scientifically and reasonably select a blister packaging machine that suits their needs is the first task that every manufacturer must seriously consider in the process of equipment selection.

When selecting a blister packaging machine, several key factors should be prioritized. These factors not only determine the machine's suitability but also directly affect production efficiency and product quality.

First, you need to assess your production needs to choose the appropriate machine. If your production scale is small, a manual or semi-automatic blister packaging machine may suffice. However, for large-scale production, a fully automatic high-speed machine is more suitable.

Production Volume: Clearly define your production volume needs—whether for small batches or mass production. For large-scale lines, high-speed blister packaging machines can provide faster production speeds, ensuring a high output in the shortest time.

Speed and Capacity: The speed of the blister packaging machine directly influences production efficiency. You need to ensure that the machine’s packaging speed and capacity align with your existing production line to avoid wastage from insufficient or excessive capacity.

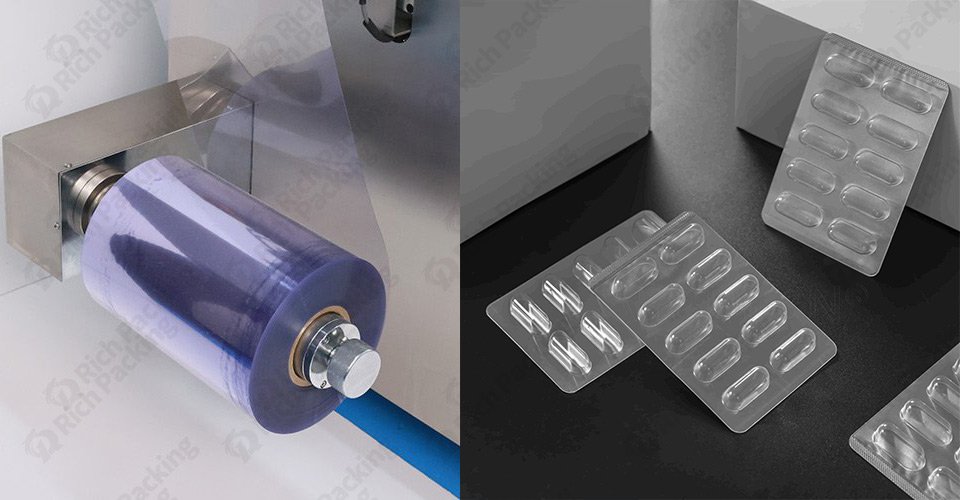

The type of blister packaging materials is another important consideration when choosing a machine. Different products require different packaging materials, such as PVC, PVDC, and aluminum. Ensure that the equipment is compatible with these materials.

Types of Materials: PVC and PVDC are common blister packaging materials that provide good product protection. However, if you need higher barrier properties or a special protective layer, such as for light-sensitive medications, aluminum packaging might be the better choice.

Product Safety: Ensure that the blister packaging machine can handle the materials you use and guarantee sealing and integrity to avoid quality issues.

Modern blister packaging machines often offer high levels of customization and flexibility to meet various product packaging needs. Based on the product type and process requirements, the machine's adaptability and features become significant considerations.

Customization Options: You can select machines with different molds, tooling, and automation levels according to your needs, ensuring the equipment can flexibly handle various product forms and packaging specifications.

Applicable Product Types: Some blister packaging machines can package not only tablets and capsules but also syringes and medical devices. This versatility can help save on equipment investment while enhancing production line adaptability.

The blister packaging machine must meet relevant regulations and compliance requirements, especially in the pharmaceutical and medical sectors, where compliance is critical. Ensure that the equipment adheres to the standards in your market, such as GMP certification in the EU or FDA standards in the U.S.

GMP Standards: For the pharmaceutical industry, the design, cleaning, and operation of the machine must comply with strict GMP requirements to ensure the safety and efficacy of medications.

Regional Regulations: Different countries and regions have varying packaging regulatory requirements. You need to ensure that the machine meets the legal standards in your market to avoid compliance issues later on.

Cost is an unavoidable factor when selecting a blister packaging machine. You need to weigh the initial investment against long-term operational costs to ensure that the equipment remains cost-effective throughout its lifecycle.

Initial Investment: High-quality fully automatic blister packaging machines typically come with a higher purchase price, but their production efficiency and stability often allow for cost recovery over time.

Operating Costs: Consider energy consumption, maintenance, and training for operators. Choosing a machine that is energy-efficient and easy to maintain can save costs in the long run.

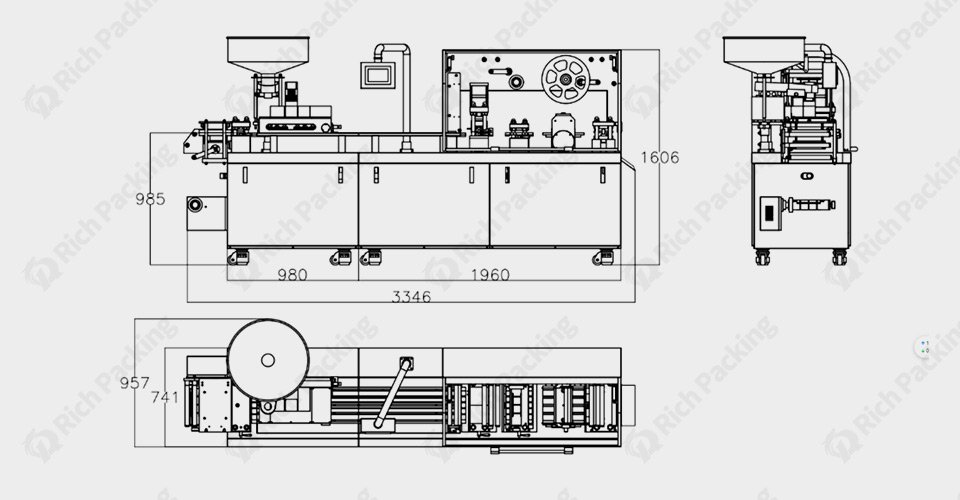

When choosing a blister packaging machine, consider the physical size of the equipment and how it affects your existing production layout. Ensuring that the machine installation and layout can fully utilize your production space is crucial for efficient operation.

Machine Size: Blister packaging machines vary in size. You need to select a model based on the actual space available in your production facility to avoid installation issues due to insufficient space.

Installation and Setup: Make sure the machine has enough operational and maintenance space during installation to facilitate smooth operation and repairs.

The reliability of a blister packaging machine goes beyond its performance; it also hinges on the support and service offered by the manufacturer. Choosing a supplier with a robust after-sales service network and technical support can ensure that any issues arising during production are quickly resolved, preventing downtime.

Technical Support: Blister packaging machines will inevitably encounter faults or require maintenance during regular production. Ensure that the supplier provides comprehensive technical support and remote assistance to help resolve issues quickly.

Spare Parts Availability: Maintenance and replacement parts also require prompt availability. Choosing a supplier with a global supply chain ensures that you won’t face delays in production due to a lack of spare parts.

One blister packaging machine that stands out is the DPP-270max Blister Packing Machine from Rich Packing. Known for its reliability and advanced features, this machine is ideal for pharmaceutical and consumer goods industries looking for a high-speed, fully automatic solution. Here’s why the DPP-270max deserves your consideration:

High Efficiency: The DPP-270max offers an impressive packaging speed of up to 200 blisters per minute, making it highly efficient for large-scale production environments.

Material Versatility: This machine supports a wide range of materials, including PVC, PVDC, and aluminum foil, offering flexibility for different product packaging needs.

Easy Operation: With its user-friendly interface and automated features, the DPP-270max simplifies operation, reducing the learning curve for operators.

Customizable Molds: The DPP-270max offers flexible mold change options, allowing you to easily adapt the machine to various packaging specifications and product forms.

Compact Design: Despite its high-speed capabilities, the machine’s compact design ensures it fits well into production spaces without requiring excessive installation room.

Compliance Ready: The machine is designed in accordance with GMP requirements, ensuring that it meets the regulatory standards necessary for pharmaceutical packaging.

By integrating the DPP-270max Blister Packing Machine into your production line, you can enjoy enhanced productivity, lower downtime, and greater flexibility to meet diverse packaging demands.

Selecting the right blister packaging machine is not merely about evaluating equipment performance; it’s a comprehensive assessment of production efficiency, product quality, and compliance. By thoroughly analyzing production needs, material compatibility, machine features, and costs, you can ensure that your decision supports the long-term development of your business.