Categories

New Blog

Tags

When you operate in the pharmaceutical packaging industry, you know that the quality of your final product is directly influenced by the performance of your machinery. The High-Speed Tablet Press is a critical piece of equipment that compresses powders into solid tablets at rapid speeds. With an emphasis on die design for high-speed tablet presses, this guide will provide you a thorough understanding of tabletting fundamentals. You will learn how mechanical forces, material properties, and advanced design features work together to create efficient, reliable tablets. Let’s dive into the intricate world of tablet compression and discover the keys to maximizing production efficiency.

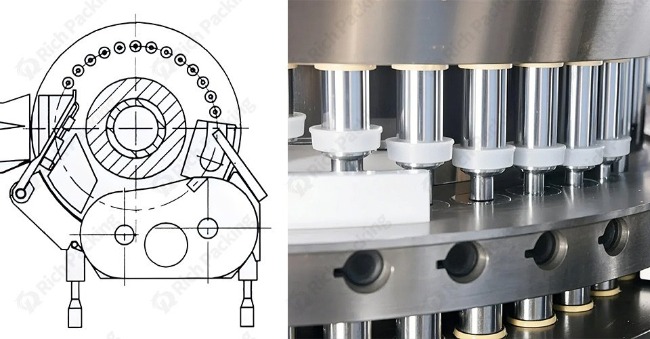

The High-Speed Tablet Press is engineered to compress a blend of active pharmaceutical ingredients (APIs) and excipients into uniform tablets. The material is shaped and compressed using precisely engineered dies in this process. The die, a metal component with a cavity that defines the tablet's shape, is where the transformation happens. As you work with these machines, it’s important to grasp the core principles of tabletting: consistent powder flow, accurate dosing, controlled compression force, and the impact of die geometry on tablet quality.

In your facility, the tabletting process begins with a well-mixed powder blend that is fed into the press. The powder enters the die cavity, where a set of punches apply pressure to form the tablet. This high-speed process requires precise control of variables such as compression force, dwell time, and powder characteristics to produce tablets with consistent weight, hardness, and dissolution profiles. You must understand that the design of the die directly affects these outcomes, making it a crucial element in tablet production.

The tablet compression process is a symphony of mechanical actions that converts loose powder into a solid dosage form. As you observe the operation of a High-Speed Tablet Press, you will notice several key stages:

Each stage of this procedure adds to the overall caliber of your tablets. The speed and accuracy of the High-Speed Tablet Press rely on the precise coordination of these mechanical actions, and understanding each phase is essential to troubleshooting and optimizing production.

The design of the die in a High-Speed Tablet Press Machine is fundamental to the tabletting principle. The die not only defines the tablet’s shape and size but also influences critical quality attributes such as weight uniformity, hardness, and disintegration behavior.

The geometry of the die is a complex interplay of dimensions and angles. When you examine a tablet press die, you will notice features such as:

Die design also involves selecting the appropriate materials. High-speed operations demand materials that are wear-resistant and maintain precision over prolonged use. Common materials include hardened steel alloys, which provide durability and consistency. You must ensure that the material chosen for the die can withstand the high compression forces without significant wear or deformation.

The precision in die manufacturing is paramount. Tight tolerances ensure that every die performs consistently, leading to uniform tablets. Variability in die dimensions can lead to fluctuations in tablet weight and thickness. In your operations, investing in high-quality dies with exact tolerances can significantly improve the overall performance of your High-Speed Tablet Press.

Numerous factors impact the performance of your tablet press and the quality of the tablets produced. As you work with a High-Speed Tablet Press, consider the following:

The compression force applied during the tablet pressing process is critical. As you adjust the force, you will see its direct impact on tablet hardness and disintegration. Finding the optimal force is a balancing act:

Proper alignment between the die and punches ensures that the tablet is uniformly compressed. Uneven pressure distribution from misalignment can produce tablets with erratic forms and variable quality. Maintaining correct alignment requires routine calibration and upkeep.

In a High-Speed Tablet Press, the dwell time—the duration during which the punches are in contact with the powder—is critical. A short dwell time may not allow sufficient compression, while an excessively long dwell time can lead to over-compression and degraded tablet quality. You need to optimize the speed and dwell time based on the formulation and die design to achieve consistent results.

To maximize the efficiency and performance of your High-Speed Tablet Press, you must implement optimization techniques that address both the mechanical and process-related aspects.

Upgrading certain machine components can also boost performance:

It is crucial to put strict quality control procedures into place:

A well-maintained High-Speed Tablet Press ensures continuous production and minimizes downtime. Regular maintenance routines and prompt troubleshooting can prevent issues that compromise tablet quality.

Establish a scheduled maintenance program that includes:

Even with preventative maintenance, issues may arise. Here are some common problems and their solutions:

Weight Variation:

Tablet Capping or Lamination:

Die Wear and Damage:

By addressing these issues promptly, you can maintain a high level of performance and reduce the likelihood of production interruptions.

The pharmaceutical industry continuously evolves, and advancements in High-Speed Tablet Press technology are causing efficiency and quality to rise dramatically. Keeping up with these advancements can help you gain a competitive advantage.

Modern dies and punches are now manufactured using advanced materials and coatings that enhance durability and reduce friction. For instance, ceramic coatings and specialized alloys can extend the lifespan of the components and improve the consistency of tablet compression.

Integration of IoT technology has transformed tablet press operations. Real-time data collection, automated parameter adjustments, and predictive maintenance systems allow you to monitor machine performance closely. These innovations help reduce downtime and improve overall efficiency.

Newer models of High-Speed Tablet Press Energy efficiency is a consideration in the design of machinery. In addition to lowering energy usage, improved drive systems and sophisticated motors also help to cut operating expenses. These upgrades might have a big financial impact as energy prices keep rising.

Emerging digital twin technology enables you to create virtual models of your tablet press operations. You can experiment with various parameters without interfering with real production by modeling the production process. This technology offers insightful information that can promote ongoing development.

To maximize the performance of your High-Speed Tablet Press, you must adopt best practices that encompass both operational procedures and technological upgrades.

Develop and enforce robust SOPs for all aspects of tablet production. Clear guidelines for machine operation, maintenance, and troubleshooting ensure that every team member understands their role in maintaining high efficiency.

Operators must get ongoing training. Make sure your employees are knowledgeable on the newest tools and methods for pressing tablets quickly. Competent operators can minimize downtime and increase output by promptly identifying problems and modifying machine settings.

Use data analytics to keep an eye on important performance metrics like energy usage, error rates, and manufacturing throughput. Make well-informed judgments regarding equipment improvements, maintenance plans, and process modifications using this data.

To cut waste and optimize production processes, apply lean manufacturing strategies. Value stream mapping and kaizen are two strategies that can assist you in finding inefficiencies and promoting ongoing development.

Real-world examples can provide valuable insights into the effective use of High-Speed Tablet Press technology. Consider the following case studies:

A leading pharmaceutical company integrated advanced sensor technology with their high-speed tablet press. By monitoring weight variations in real time and adjusting compression force dynamically, they reduced weight variability by 20%, enhancing product consistency and regulatory compliance.

Another manufacturer upgraded to a next-generation high-speed tablet press featuring IoT connectivity and automated quality control. This upgrade led to a 30% increase in production throughput and a significant reduction in downtime, showcasing the economic benefits of technological innovation.

A facility focused on predictive maintenance by installing real-time monitoring sensors on their tablet press dies. The data collected allowed for early detection of wear, leading to scheduled maintenance that minimized production interruptions and improved overall efficiency.

These case studies demonstrate how continuous improvement and technological upgrades can drive significant performance gains in high-speed tablet pressing operations.

The future of High-Speed Tablet Press technology is bright, with continuous innovations shaping the way you manufacture tablets. Some of the trends to watch include:

Future dies will likely incorporate even more precise machining and advanced materials, further reducing wear and improving consistency. The integration of computer-aided design (CAD) and simulation software will allow for optimized geometries that enhance tablet quality.

The trend toward full automation will continue to grow, with machine learning algorithms playing a greater role in process optimization. These systems will automatically adjust parameters in real time, ensuring that each tablet is produced with minimal variation.

Environmental considerations are driving the development of more energy-efficient and sustainable high-speed tablet presses. As you invest in new equipment, consider models that not only boost production but also reduce your facility’s carbon footprint.

The integration of digital twin technology, AI analytics, and IoT will create more resilient and adaptable production systems. These innovations will allow you to simulate, monitor, and optimize your operations like never before.

Modernizing your production line is critical for maintaining competitive advantage. Consider the following equipment and tools to enhance your High-Speed Tablet Press operations:

| Equipment Type | Function | Key Benefits |

|---|---|---|

| Tablet Press Die | Shapes and compresses powder into tablets | Ensures uniformity, quality, and precise dosage |

| Automated Feeding System | Delivers a consistent powder flow into the die cavity | Reduces variability and increases production speed |

| IoT Sensors & Data Loggers | Monitor real-time performance and machine health | Enables predictive maintenance and process control |

| Control Software | Integrates automation and adjusts operational parameters | Improves consistency and reduces human error |

These tools, when integrated with your high-speed tablet press, allow for a fully optimized production line that delivers superior quality and efficiency.

As you optimize your tablet production, integration with your supply chain and adherence to regulatory standards remain crucial. The efficiency of your High-Speed Tablet Press is not only a function of machine performance but also of seamless coordination with upstream and downstream processes.

Ensure that your raw material sourcing, inventory management, and packaging processes are aligned with your tablet production. Consistency in material quality and timely supply can directly impact the performance of your high-speed tablet press.

Compliance with GMP, FDA, and EMA standards is non-negotiable. Maintain rigorous documentation of your production processes, quality control tests, and maintenance schedules. This will help you build a robust quality management system and meet regulatory requirements consistently.

Data-driven insights are key to optimizing your high-speed tablet press operations. You can find bottlenecks, modify process settings, and apply ongoing improvements by gathering and evaluating production data..

Monitor metrics such as:

Using this data, you can implement corrective measures and refine your production strategy, ensuring that your high-speed tablet press operates at peak efficiency.

To maximize the performance of your high-speed tablet press, follow these practical guidelines:

These measures will help you maintain a competitive edge and consistently produce high-quality tablets.

Understanding the tabletting principle of a High-Speed Tablet Press die is key to optimizing your pharmaceutical production. By mastering die design, process optimization, and quality control, you can enhance tablet quality and efficiency. For further inquiries or personalized consultation, please contact us today.