Categories

New Blog

Tags

In the pharmaceutical manufacturing realm, the NJP - 3800D Capsule Encapsulation Filling Machine has emerged as a top choice, offering a plethora of features that set it apart from the competition.

NJP-3800D automatic capsule filling machine main features

The NJP - 3800D offers an impressive maximum filling capacity of 228,000 capsules per hour. This enables pharmaceutical companies to meet large - scale production demands efficiently, reducing production time and costs.

New Pneumatic Discharging Mechanism

It provides better filling results for materials with poor flowability, ensuring accurate and consistent filling.

Vacuum Powder Feeding Machine

The vacuum powder feeding machine enables smooth and consistent powder flow, minimizing wastage and spillage.

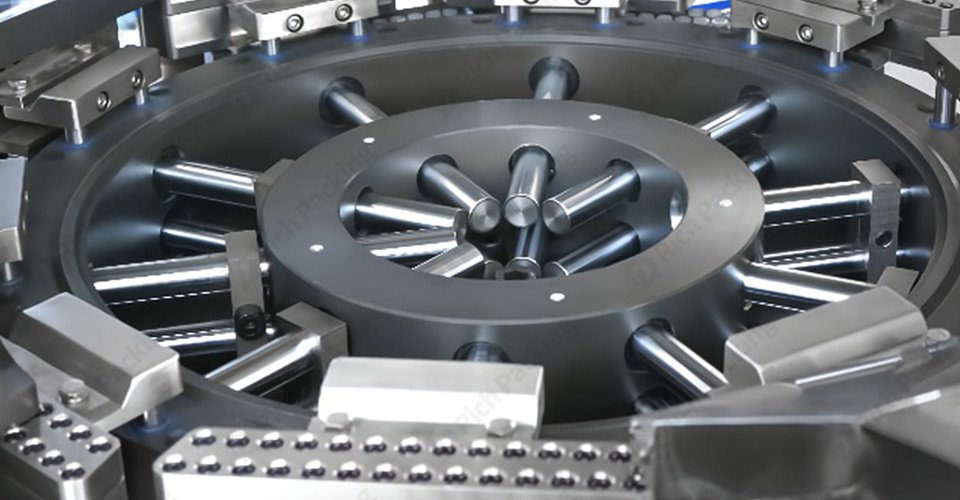

Precision Divider

Features a German Zeiss optical dividing head with a 3 - second division. The division axis is machined in a single operation, ensuring high dosing accuracy with an error of ≤3%.

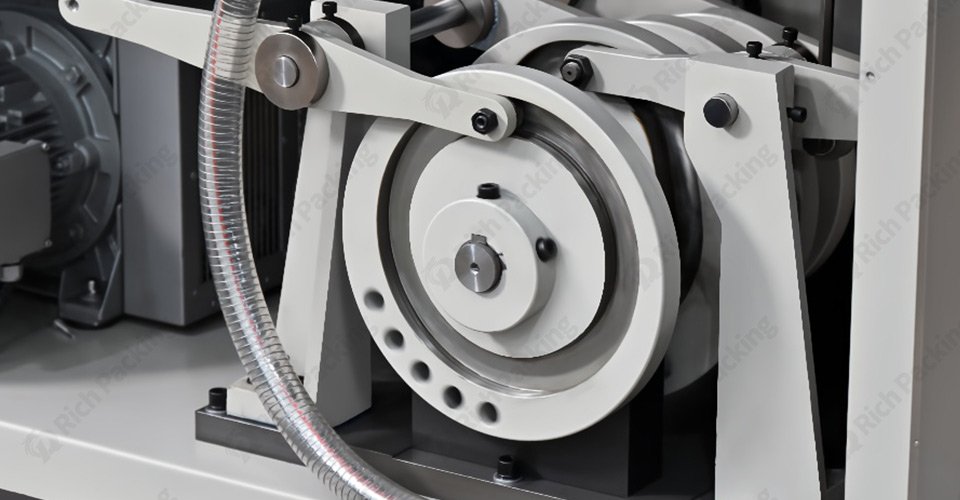

CNC - Machined Internal Groove Cam

This Capsule Filling Machine features an internal groove cam made in single operation from a CNC machining center, ensuring no seams or gaps for better stability. This design allows the drive mechanism to operate quietly during high - speed production.

Patented Turntable Design

The turntable design is patented and uses SIL - imported silicone sealing rings to effectively prevent powder from entering. It has excellent sealing properties with no dust leakage; the double - axis horizontal design employs PTFE oil - free bearings, requiring no lubrication or maintenance for life. Modular structure, allowing for easy point operation and disassembly for cleaning, with mold changes completed within 15 minutes.

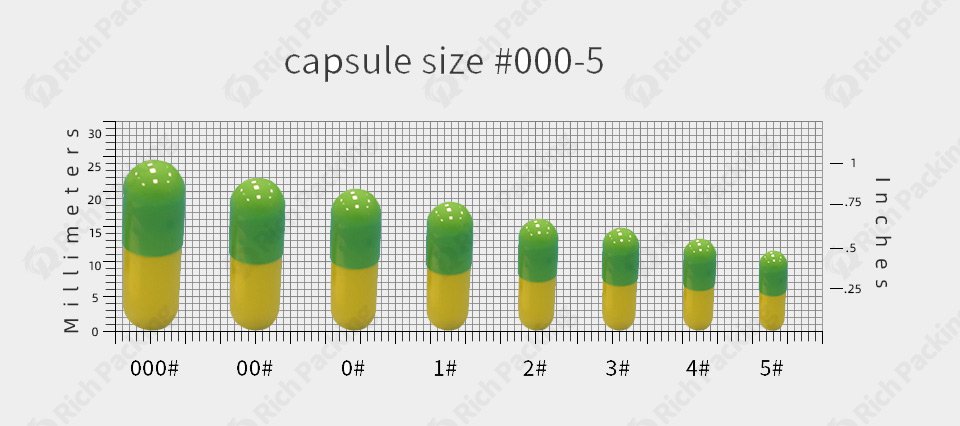

3. Versatility

Can handle a wide range of capsule sizes from 000 to 5#. Accommodates various formulations such as powder, granule, pellet, and tablet. It maintains a filling accuracy of ±3% for Western medicine and ±4% for Chinese medicine.

4. Quality Assurance

GMP Compliance

◦ The machine is designed to comply with GMP requirements. For example, it is equipped with a timed oil supply system that injects lubricant at set intervals, ensuring continuous lubrication of the cam mechanism, guaranteeing a smooth operation of the drive system.

• Certifications

◦ Holds certifications including cGMP, CE, ISO, and SGS, adhering to strict international quality and safety standards. This guarantees the reliability and compliance of the machine in pharmaceutical production.

Intuitive Interface

The Siemens human - machine interface provides real - time counting and can be equipped with printing devices upon customer request to print production dates, batch numbers, and codes. This simplifies the operation process, allowing operators to easily monitor and control filling parameters. This reduces the learning curve for new operators.

Easy Access

The machine's layout permits easy access to critical components, facilitating routine maintenance and troubleshooting.

Richpacking offers comprehensive after - sales services. This includes a 3 - year warranty, a team of engineers for on - site support overseas, a complete set of technical files for installation and maintenance, and on - site debugging services with reasonable charges.

|

Name |

Details |

|

Production capacity |

228,000 pcs/h |

|

Net weight of machine |

2200Kg |

|

Overall size of machine |

1395×1180×2200 |

|

Power |

380/220V 50Hz |

|

Total power |

10.5KW |

|

Applicable capsule |

000,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

In conclusion, the NJP - 3800D combines multiple advantages, making it an ideal choice for pharmaceutical manufacturers seeking to optimize their production processes and ensure product quality.