Categories

New Blog

Tags

In pharmaceutical manufacturing, the feeding and filling of tablet presses are critical for achieving consistent quality and efficiency. From understanding powder flow dynamics to optimizing filling mechanisms, these processes form the backbone of tablet production. This article dives deep into how feeding and filling systems work, their challenges, and ways to optimize them.

Feeding and filling mechanisms ensure that the exact quantity of material enters the die for compression into tablets. Improper feeding can result in inconsistent weight, uneven hardness, and reduced product quality. Efficient systems not only ensure uniformity but also improve productivity and reduce waste.

Key aspects include:

· Maintaining a consistent powder flow.

· Achieving accurate weight and density in tablets.

· Reducing material loss and downtime.

Gravity Feeders

These rely on gravity to move powder into the dies. Best suited for free-flowing powders, they are simple but may not handle cohesive materials well.

Force Feeders

Force feeders use rotating paddles or screws to push powder into the dies, ensuring uniform filling even with poorly flowing materials.

Gravity feeders are among the simplest and most widely used feeding mechanisms in tablet presses, especially for materials with excellent flow properties. They rely on the natural force of gravity to channel powder or granules from a hopper into the die cavities. While straightforward in design, their effectiveness depends heavily on the physical properties of the material being processed.

· The material is stored in a hopper positioned above the tablet press.

· Gravity allows the powder to flow downward through a chute or nozzle directly into the dies.

· As the die table rotates, the dies pass under the hopper, filling with powder before compression.

Simplicity and Cost-Effectiveness:

The design is minimalistic, making gravity feeders cost-effective and easy to maintain.

High-Speed Operation:

Gravity feeders can keep up with high-speed production when the material flows smoothly.

Energy Efficiency:

No additional mechanical or electrical components are required, reducing operational costs.

Material Dependency:

Gravity feeders are highly effective for free-flowing powders, but cohesive or poorly flowing materials may lead to blockages or uneven die filling.

Risk of Segregation:

When powders contain particles of varying sizes or densities, segregation may occur during flow, resulting in inconsistent tablet composition.

Limited Control:

Unlike force feeders, gravity feeders offer less control over the filling process, making them less suitable for precise weight requirements.

Gravity feeders are ideal for:

· Simple formulations with good flowability.

· High-volume production of non-critical tablets where precision is less stringent.

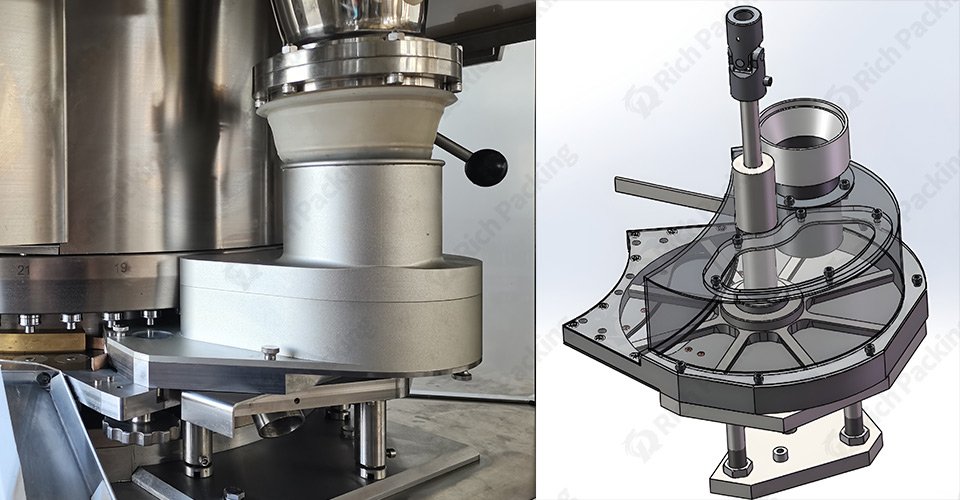

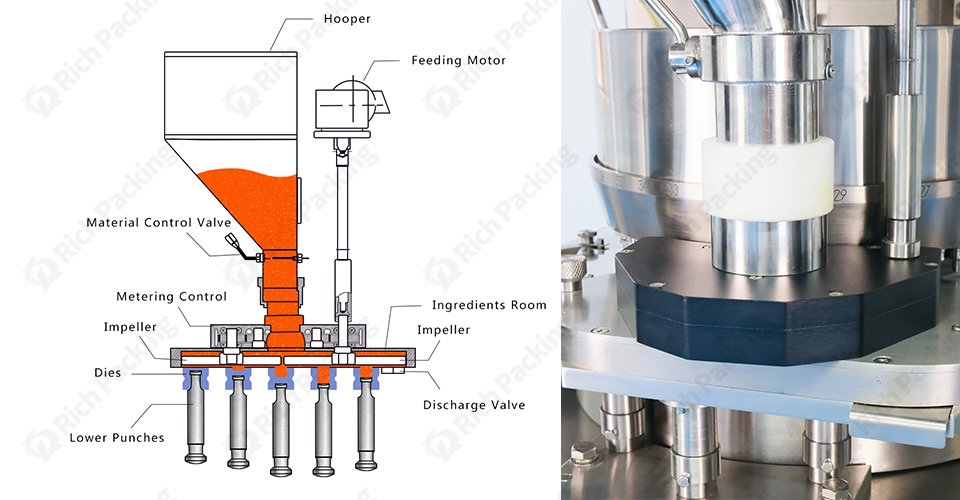

Force feeders are a more advanced feeding mechanism, designed to address the limitations of gravity feeders. They use mechanical components, such as rotating paddles or screws, to actively push the material into the dies, ensuring uniform filling and overcoming flow challenges.

· Material flows from the hopper into a feeding chamber equipped with paddles or screws.

· The rotating paddles create a controlled flow of powder, pushing it into the die cavities.

· This mechanical action ensures consistent filling, even with difficult-to-handle materials.

Enhanced Flow Control:

Force feeders regulate powder flow, ensuring uniform die filling regardless of material properties.

Compatibility with Poorly Flowing Powders:

Cohesive or sticky materials that would clog a gravity feeder are effectively managed by the mechanical action of force feeders.

Consistent Tablet Weight:

By evenly distributing the material, force feeders help maintain precise tablet weight, improving product quality.

Reduced Segregation:

The mixing action of the paddles minimizes segregation, maintaining a uniform blend throughout production.

Higher Cost and Complexity:

Force feeders are more expensive and require more maintenance due to their mechanical components.

Energy Consumption:

The additional moving parts consume more energy compared to gravity feeders.

Possible Overheating:

Friction from the paddles can generate heat, which may affect sensitive formulations.

Force feeders are best suited for:

· Complex formulations with poor flow properties.

· Tablets requiring precise weight and density control.

· High-speed production environments where consistency is critical.

|

Feature |

Gravity Feeders |

Force Feeders |

|

Material Suitability |

Free-flowing powders |

Cohesive or poorly flowing powders |

|

Control |

Limited control over flow and filling |

Precise and consistent flow control |

|

Cost |

Low |

Higher due to complexity |

|

Maintenance |

Minimal |

Requires regular upkeep of moving parts |

|

Segregation Risk |

Higher risk |

Reduced due to active mixing |

|

Production Speed |

High for suitable materials |

High for all material types |

Powder flow characteristics directly impact the efficiency of feeding systems. Materials with good flowability ensure consistent die filling, while cohesive or irregular powders can cause blockages and weight variability.

Factors affecting powder flow:

· Particle size and shape.

· Moisture content.

· Bulk density and compressibility.

Accurate filling is vital for ensuring uniform tablet weight and potency. Tablet presses typically use volumetric or gravimetric methods for filling.

In this method, the volume of powder in the die determines tablet weight. Adjusting the fill depth allows for control over tablet size and weight.

Advantages:

· Simple and fast.

· Ideal for high-speed production.

Challenges:

· Susceptible to variability with inconsistent powder flow.

Gravimetric filling measures the weight of the material in the die, ensuring precise dosage.

Advantages:

· Highly accurate, especially for low-dosage tablets.

· Suitable for critical applications requiring exact dosages.

Challenges:

· Slower than volumetric filling.

· Requires advanced sensors and controls.

Selecting a tablet press with advanced feeding and filling systems is essential for maintaining high-quality standards. Modern machines like rotary tablet presses feature integrated force feeders for consistent filling.

Advanced monitoring systems, such as real-time sensors, help detect and correct deviations during feeding and filling. Automated adjustments ensure that every tablet meets the desired specifications.

Inconsistent Tablet Weight

o Cause: Uneven powder flow or improper feeder settings.

o Solution: Use force feeders and optimize paddle speed.

Powder Segregation

o Cause: Particle size differences during feeding.

o Solution: Blend materials thoroughly and use appropriate feeders.

Rotary tablet presses are a cornerstone of modern tablet manufacturing. They combine high-speed operation with precision filling and compression, making them ideal for large-scale production.

Features of Rotary Tablet Press Machines:

· Multi-station turrets for high output.

· Force feeders for uniform filling.

· Real-time monitoring for quality control.

Continuous manufacturing systems integrate feeding, filling, and compression into a seamless process, reducing downtime and material waste.

IoT-enabled sensors and predictive analytics help identify potential issues in feeding and filling systems before they lead to production downtime.

The feeding and filling of tablet presses are vital for producing high-quality pharmaceutical tablets efficiently. By understanding these processes and investing in advanced equipment like rotary tablet presses, you can optimize production and ensure consistent results.

Have questions or need guidance? Contact us today to explore solutions tailored to your manufacturing needs!