Categories

New Blog

Tags

Have you ever wondered how the tablets you take every day are made? As a pharmaceutical industry professional, it's important for you to understand how tablet presses work. This guide will provide you with a comprehensive understanding of tablet press operations, boosting both your knowledge and productivity.

Basic Concepts of a Tablet Press

A tablet press is an advanced mechanical device designed to compress powdered or granular materials into tablets of precise shapes and sizes. As a core piece of equipment in the pharmaceutical industry, it is also widely used in food supplements, chemicals and other industries that require solid dosage forms.

It is important for you to understand how tablet presses work. Whether you are a line manager, equipment purchaser, or process improvement engineer, a thorough understanding of this equipment will help you optimize your production process, improve product quality, and make informed equipment-related decisions.

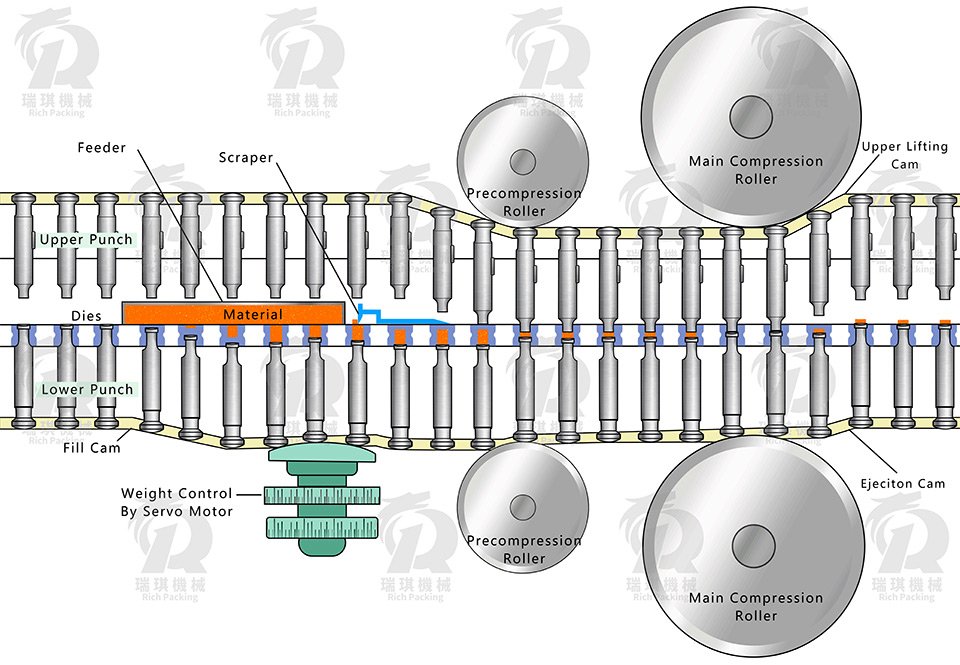

To fully understand how a tablet press works, you first need to familiarize yourself with its core components:

1. Hopper and feed system: This is the starting point for your raw material to enter the tabletting process. The hopper design needs to ensure that the material is delivered evenly and consistently to the compression zone. Some advanced systems are also equipped with a vibration device or forced feed mechanism to prevent bridging of the material and ensure consistent feed.

2. Compression zone: This is the most critical part of the tabletting process. In this area, your material will be pressed under high pressure into the desired shape. The compression zone usually consists of an upper punch, a lower punch, and a die.

3. Punches and Dies: These components determine the final shape and size of your tablets. The design of the punch directly affects the distribution of compression forces, while the die defines the shape of the tablet. Depending on your product needs, you may need to select different types of punches and dies.

4. Discharge system: Once compression is complete, your tablets need to be safely removed from the mold. A properly designed discharge system ensures that the tablet remains intact and avoids cracking or breaking.

Step-by-Step Explanation of the Tablet Pressing Process

Now, let's take a closer look at each step of the tabletting process:

1. Feeding: Your ingredients are transported from the hopper through the feeding system to the compression zone. This step needs to be precisely controlled to ensure a consistent amount of material is compressed each time. If you notice inconsistencies in the weight of the final product, something is probably wrong with this step.

2. Compression: In this stage, the upper and lower punches move simultaneously towards the mold, exerting tremendous pressure on the raw material. The amount and duration of pressure directly affects the hardness and solubility of your tablets. You need to adjust these parameters for different formulations and desired release characteristics.

3. Discharge: Once the compression is complete, the lower punch rises and pushes the formed tablet out of the mold.This procedure demands meticulous attention to prevent any damage to the tablet. If you notice scratches or nicks on the surface of the tablets, it may be due to the expulsion process not being smooth enough.

4. Cleaning: At the end of each cycle, the die and punch surfaces need to be cleaned to prevent residue from affecting the next tablet press. Thorough cleaning on a regular basis is essential to maintain the quality of your product and the life of your equipment.

Comparison of Different Types of Tablet Presses

Depending on your production needs, you may choose different types of tablet presses:

1. Single Punch Tablet Press: Ideal for small-scale production or the R&D phase. If you need to change molds or adjust parameters frequently, this type of tablet press will give you more flexibility.

2. Rotary Tablet Press: This is ideal when you need to increase production capacity. Multiple compression stations work simultaneously, greatly increasing productivity. However, please note that commissioning and maintenance of this type of machine may be more complicated.

3. Multi-layer tablet press: If you have a complex product formulation that requires the production of multi-layer tablets, this type of press can meet your needs. It allows the formation of multiple layers of different ingredients in a single pressing process.

To ensure that your tablet pressing process is stable and controllable, you need to pay close attention to the following key parameters:

1. Pressure control: Pressure directly affects tablet hardness and solubility. You need to adjust the pressure according to the raw material characteristics and target product attributes. Excessive pressure may result in tablets that are too hard and affect dissolution, while insufficient pressure may result in tablets that are fragile and prone to breakage.

2. Speed Adjustment: Pressing speed affects throughput, but it also affects tablet quality. Higher speeds may result in uneven filling or inadequate compression. You need to find a balance between yield and quality.

3. Fill depth: This determines the weight of each tablet. Precise control of fill depth ensures accurate dosing. You may need to adjust this parameter taking into account the fluidity and compressibility of the ingredients.

4. Pre-compression: For some formulations, the pre-compression step can significantly improve the quality of the final product. It helps to expel air, reduce delamination, and allow for more uniform final compression. If your product has problems with mold sticking or cracking, consider adding a pre-compression step.

During the tablet compression process, you may encounter the following common problems:

1. Tablet cracking: This can be caused by too much pressure, too fast a discharge rate, or the characteristics of the raw material itself. You can try to solve this problem by adjusting the pressure, increasing the binder or changing the discharge rate.

2. Inconsistent weight: This usually stems from a problem with the feed system or improper control of fill depth. Make sure your feed system is working properly and check and calibrate the fill depth setting regularly.

3. Sticky Mold Problems: This can be caused by excessive moisture in the raw material or improper mold surface preparation. You may consider adding an anti-stick agent to your formula or improving your mold surface treatment process.

4. contamination problems: to ensure compliance with GMP standards, you need to establish strict cleaning protocols, including regular deep cleaning and equipment maintenance.

Understanding how tablet presses work is critical to optimizing your production process. By acquiring this knowledge, you can increase efficiency, improve product quality, and stay ahead of the curve in a competitive marketplace. We hope this guide enhances your understanding and operation of tablet press equipment, as well as boosts your career growth.