Categories

New Blog

Tags

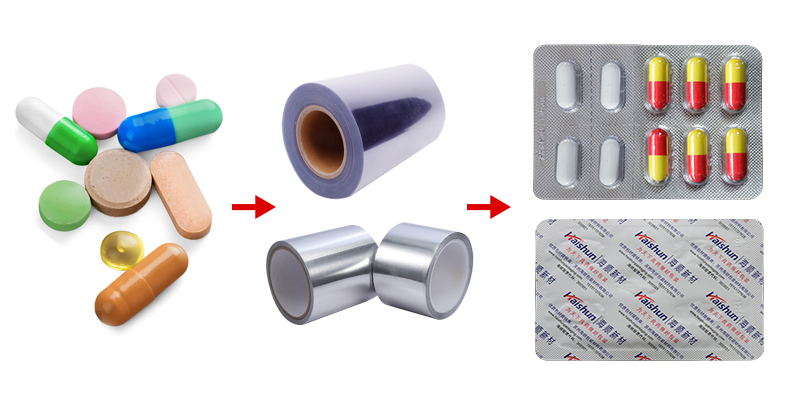

Blister packaging machine are game-changers in the pharmaceutical packing field. They offer unmatched protection for medications, improve efficiency, and ensure regulatory compliance. If you're in the pharmacy industry, understanding how these machines enhance packaging processes can help you make informed decisions about integrating them into your operations. Let's dive into their significance, applications, and innovations.

The Importance of Blister Packaging in Pharmacy

Blister packaging is more than just a way to store medications—it’s a critical tool in safeguarding products and enhancing user experience.

Your primary concern is keeping medications safe from environmental factors like moisture, light, and air. Blister packs act as a protective barrier, ensuring your products remain effective and uncontaminated throughout their shelf life. Whether you’re dealing with delicate capsules or temperature-sensitive tablets, this packaging method offers superior protection.

Patients rely on clear dosage instructions and tamper-proof seals to ensure they’re taking medications correctly. Blister packs make this possible by providing transparent, individually sealed units that prevent unauthorized access and help users adhere to prescribed dosages.

In an industry where compliance is non-negotiable, blister packaging ensures you meet FDA and international standards. These machines streamline processes, reducing the risk of cross-contamination and ensuring every pack is uniform and traceable.

Blister packaging machines cater to a wide range of needs in the pharmaceutical sector. Their adaptability and precision make them indispensable for various applications.

If you handle solid dosage forms, blister packaging machines provide unmatched precision and efficiency. Each tablet or capsule is securely sealed, ensuring consistent quality and appearance. This not only improves consumer trust but also simplifies inventory management.

Some drugs are highly sensitive to environmental factors. Blister machines, especially those using aluminum foils or cold-forming techniques, offer the robust protection required for these medications, extending their shelf life and maintaining efficacy.

With the rise of combination therapies, blister machines allow you to pack multiple drugs in a single blister. This approach simplifies the user experience while maintaining product integrity.

Whether your product requires specific branding, unique blister designs, or varying pack sizes, modern blister machines can adapt to your requirements. This flexibility makes it easier to meet market demands and enhance your product's appeal.

Adopting blister packaging machines offers numerous advantages, from operational efficiency to improved consumer satisfaction.

Automating your packaging process reduces manual labor, minimizes errors, and speeds up production. These machines handle high volumes with consistent accuracy, ensuring you meet tight deadlines without compromising quality.

Blister packaging machines optimize material usage, significantly cutting waste. With the ability to pack in bulk, you save on production costs while maintaining high standards.

Blister packs provide a clear view of the product, instilling confidence in consumers. Features like easy-to-tear perforations and single-dose accessibility enhance convenience, ensuring your product stands out in a competitive market.

Whether you're a small business or a large-scale manufacturer, blister packaging machines can be tailored to your needs. Their modular designs make it easy to scale operations as your business grows.

The pharmaceutical industry is constantly evolving, and blister packaging machines are no exception. Staying updated on these innovations can give you a competitive edge.

Modern machines are equipped with IoT capabilities, enabling real-time monitoring and automated quality checks. This ensures every package meets stringent standards while providing actionable insights for process optimization.

Sustainability is becoming a priority for many businesses. Today’s blister machines support eco-friendly materials, reducing your environmental footprint without compromising product protection.

Whether you need heat sealing for standard products or cold-forming for sensitive medications, blister machines now offer a range of advanced options to meet diverse requirements.

With so many options available, selecting the right machine can be challenging. Here’s what you should focus on:

Start by analyzing your production volume, packaging material, and design requirements. A machine suited for small-scale operations may not perform well in a high-volume setting.

Look for key features like speed, automation, and compatibility with different materials. A versatile machine ensures you’re prepared for future market demands.

Reliable technical assistance, availability of spare parts, and operator training are essential for smooth operations. Partner with a manufacturer that provides comprehensive support.

Blister packaging machines are indispensable in the pharmaceutical packaging field. They enhance product safety, streamline operations, and meet regulatory requirements, making them a valuable investment for any pharmacy business. By staying informed about their applications and benefits, you can leverage these machines to elevate your packaging processes and stay ahead in a competitive industry.