DPH-270Max Roller Blister Packing Machine

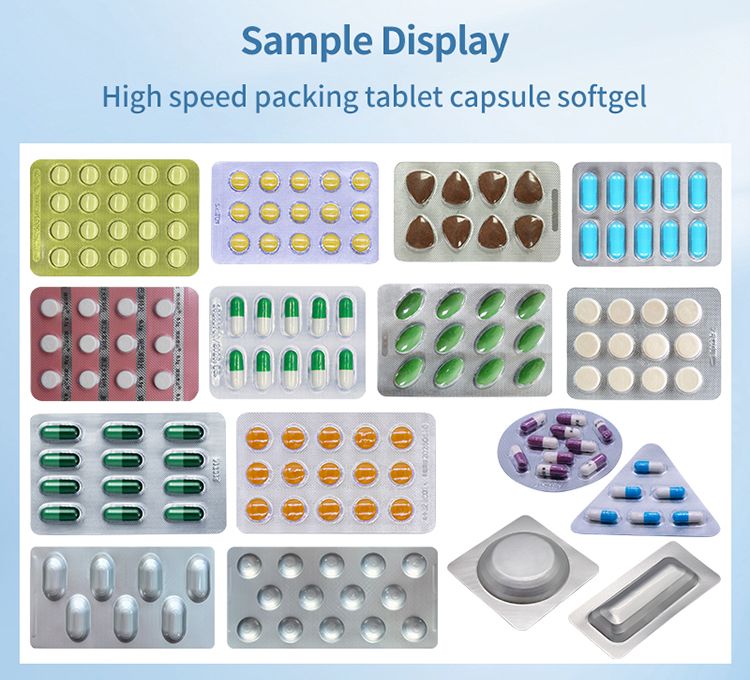

The DPH-270Max roller blister packaging machine can package various tablets, capsules, disposable medical devices, vials, etc. at high speed. It is compatible with aluminum-plastic, aluminum-aluminum, paper-plastic and other materials. The maximum packaging width of PVC and PTP reaches 260mm. It can automatically complete the functions of forming, feeding, sealing, cursor alignment, servo traction, punching and robot discharging.

The DPH-270Max high-speed blister machine adopts a partitioned modular design. The forming, heat sealing, traction, batch number indentation, punching and other stations are independently controlled and do not affect each other, so parameter adjustment and cleaning and maintenance are very convenient. According to our return visit data to old customers, it saves 58% of time compared with similar products.

The DPH-270Max fully automatic blister machine integrates digitalization and intelligence, and the mechanical transmission parts such as chains and belts are reduced by more than 85% compared with similar equipment. The service life exceeds 8 years and the operating noise is less than 70DBA.

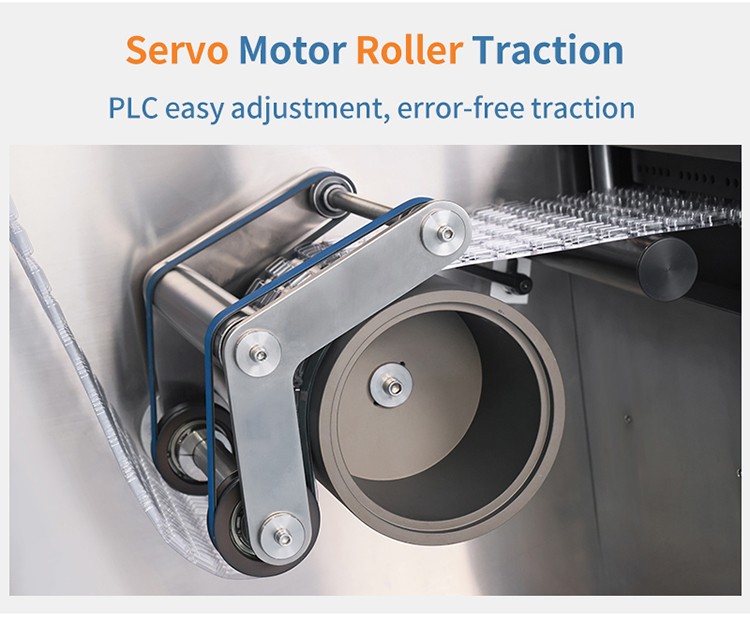

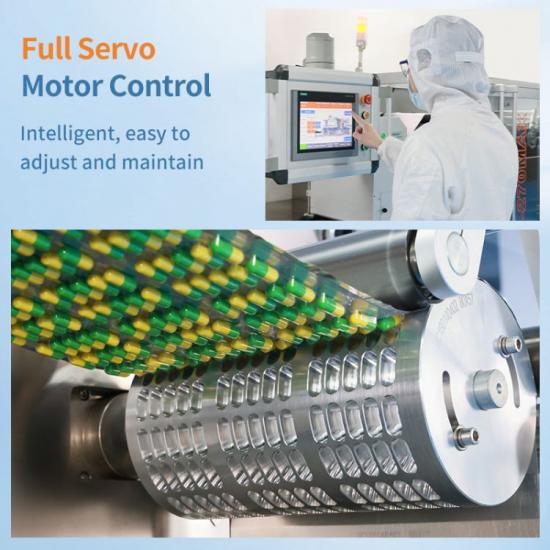

The six stations of the 270Max high-speed blister packaging machine, including forming, forming traction, heat sealing, cursor alignment, cutter, and cutter traction, are all controlled by a servo motor system, and the motion controller has autonomous intelligent tracking (when the speed of forming traction changes, the subsequent heat sealing and punching stations also automatically adjust the speed accordingly) and has a one-button reset function, which is simple to operate, convenient to maintain, low maintenance cost, and low labor cost.

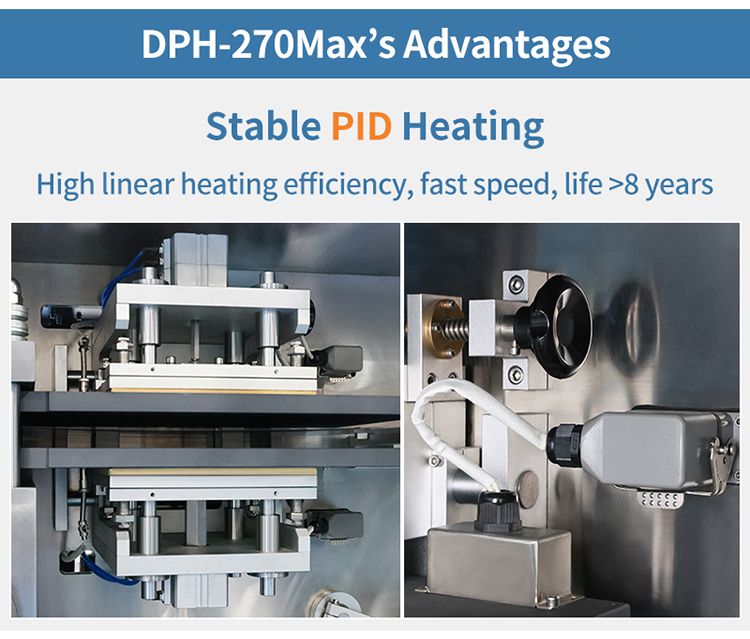

The heating station is different from the flat blister packaging machine, and adopts the PID temperature control system algorithm to achieve multi-segment linear heating with high heating efficiency. The heating plate adopts an adjustable module structure, and the surface adopts a Teflon flat coating, which has higher heat conduction efficiency. Calculated based on 8 hours of use per day, the service life of the thermoforming station exceeds 8 years.

The punching station is controlled by Siemens servo motor, which has higher control accuracy. The punching, creasing and batch number stations also use automotive industrial-grade crankshafts. Compared with traditional eccentric shafts, the DPH270Max high-speed blister packaging machine has strong pressure-bearing capacity, balanced force, high stability, and noise less than 75DBA. It is also equipped with a disassembly pedal, and daily mold changes can be completed in 10 minutes.

*** Technical parameter

|

Model: |

DPH-270Max |

|

Production Capacity: |

Max 150 cuts/min, Max 450 blisters/min |

***Configuration List

| Name | Specification | QTY. | Manufacturer |

| Oil-free vacuum pump | VT4.25 3Ph 0.75/0.9KW | 1 | Germany BECKER |

| Servo Motor | MHMF082L1U2M | 6 | Panasonic |

| Servo Drives | SV630PS5R5I | 6 | Panasonic |

| PLC Master Module | H3S-1616MT-XP | 6 | Panasonic |

| 32-axis motion controller | GM1CSEC16T | 1 | Panasonic |

| Frequency Converter | AVF200-0152 | 1 | Panasonic |

| PLC expansion modules | GL10-0016ER | 4 | Panasonic |

| PLC temperature control module | AX6-C | 1 | Omron |

| PLC touch screen | 6AV6/648-0BC11-3AX0 | 1 | Germany Siemens |

| Encoder | ZSP3806-003G-1500BZ3-5-24F | 1 | USA Avago |

| PLC Isolation Protection Module | DC-12-30V | 1 | Germany Siemens |

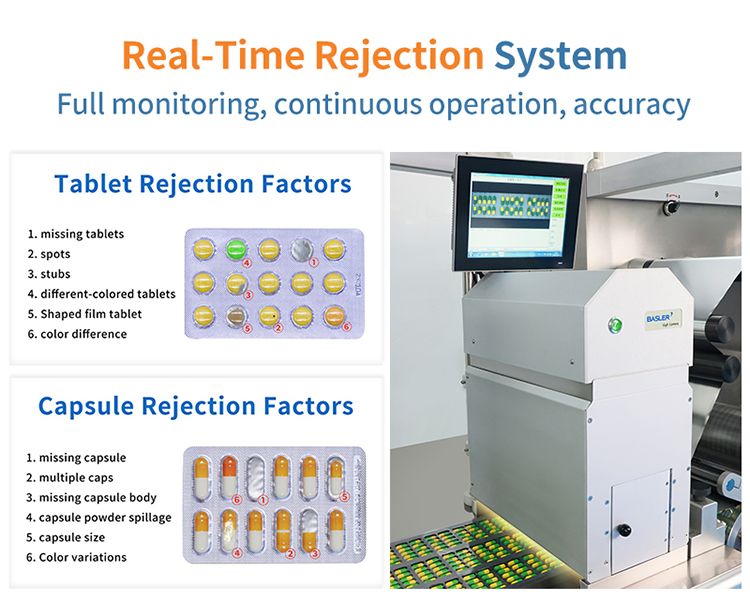

| Color camera detection system | Basler-200 | 1 | Germany, Basler |

| Digital regulating vibration controller | CUH204578CF1 | 1 | CUH |

| Main motor (electromagnetic brake) | YEJ2-100L1-4 | 1 | XINLIN |

| Solid State Relays | VFD015B43A | 6 | KSR40DA |

| Stainless steel plate | Cr12 40Cr Gcr15 45# Q235-A | / | South Korea, Japan |

| Main power switch | ABL2REM24065K | 1 | Schneider |

| Proximity switches | NPN TL-Q5MCI-Z | 17 | Omron |

IPv6 network supported

IPv6 network supported