HZP-26-40D High Speed Rotary Tablet Press

The turntable of the HZP-26-40D rotary high speed tablet press is made of high strength 2Cr13 austenitic stainless steel, combined with mixed tin QT600, with a surface hardness of HRC53 or above.

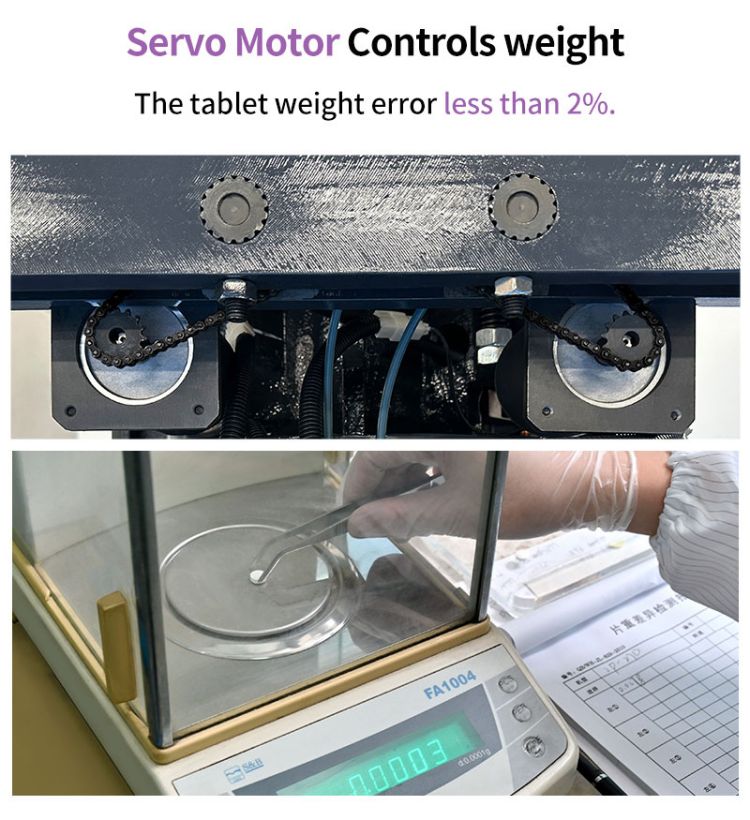

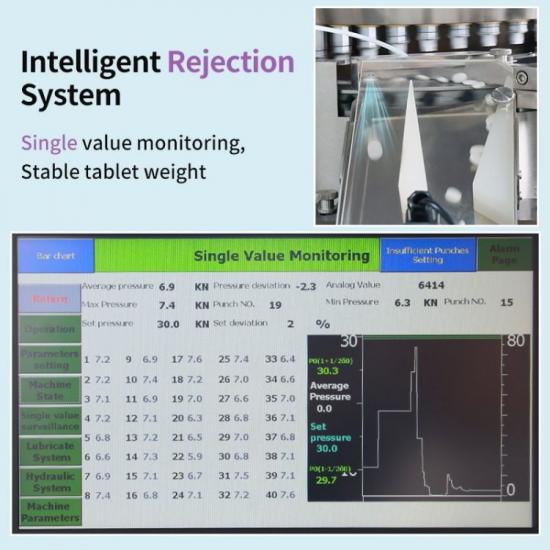

The integrated tablet weight automatic adjustment system does not require hand wheel adjustment. The Siemens servo motor controls the filling track, and the system automatically increases and decreases compensation. The average tablet weight accuracy of the tablet press is ≤±2%.

Our high-speed tablet press monitors the pressure of each die in real time, and is equipped with a real-time online detection and rejection system to automatically identify and promptly reject products with unqualified tablet weights. It can achieve batch rejection and accurate single-piece rejection.

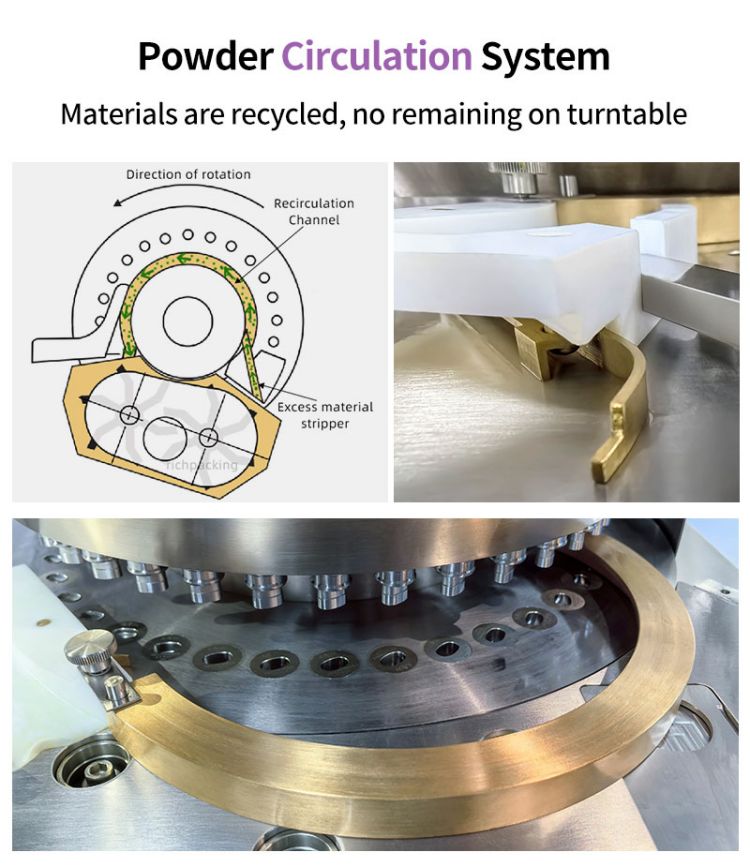

This cutting edge series of rotary tablet presses is equipped with a residual powder recycling system. The powder return turntable recycles the residual powder that flows out to the forced feeder, and there is basically no powder residue on the disk.

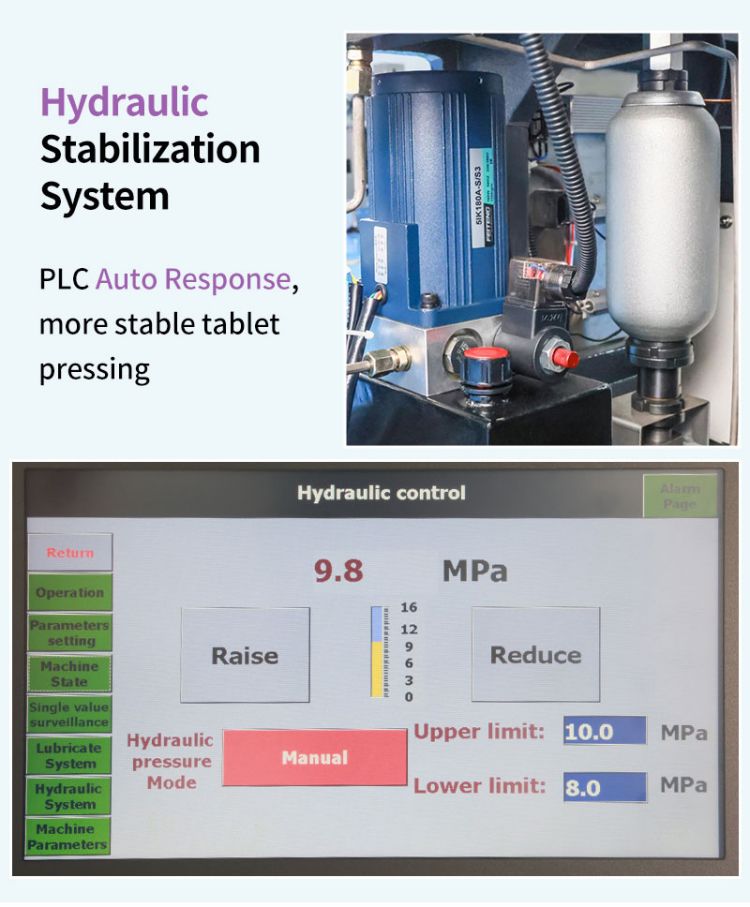

The hydraulic pressure stabilization system makes the weight of tablets produced by this tablet press stable, because the standard pressure hydraulic stabilization device, the plc automatically responds, the hydraulic pressure is stable, the stability of tablet pressing is improved, and the noise is low.

Our high capacity automatic tablet press is equipped with a truly intelligent lubrication system, which realizes the automatic sealed oil supply function of liquid and solid lubricants, and automatically lubricates the molds, guide rails, pressing wheels, bearings, etc.

*** Technical parameter

|

Model |

HZP-26/40D |

|

Max. Production Capacity |

260000 pcs/h |

|

Max. Pressure |

100KN |

|

Max. Dia. of Tablet |

25mm |

|

Max. Thickness of Tablet |

12mm |

|

Length of Upper/Lower Punching Bar |

115mm/133.4mm |

|

Rotary Speed |

5~21 r/min |

|

Motor |

5.5kw |

IPv6 network supported

IPv6 network supported