A tablet counting and filling machine is a machine specifically used to accurately count small solid objects and put them into containers. The materials that can be packaged include tablets, capsules, pills, soft capsules, soft candies, buttons, etc. The loaded containers include various bottles, prefabricated bags, cartons, metal containers, etc.

The counting filling machine usually includes the following key components and functions:

Counting system: This is the core part of the automatic counting machine, and its function is to accurately count the number of products. The first equipment used the simplest mechanical counting method. Although the efficiency was very low, it solved the basic counting needs. With the development of science and technology, modern tablet counting machines usually use photoelectric sensors, infrared detectors or other more advanced sensing technologies to achieve higher accuracy and more efficient counting and packaging.

Feeding system: that is, the material to be packaged is sent to the counting area, usually using a vibrating plate, a lifting feeder or a similar automatic feeding machine to ensure that the product to be packaged can enter the counting and packaging process stably, orderly and uninterruptedly.

Positioning system for container filling: Except for manual and semi-automatic machines, the counting machine is equipped with a positioning system as standard. The function of this system is to ensure that the bottle, pouch or other container is accurately aligned with the filling port. This ensures that once the container is in place, the accurately counted product is automatically and quickly loaded into the container.

Capping system (optional): When the packaging container is a bottle, some models of counting and filling machines integrate an automatic capping function, which can tighten the bottle cap on the bottle mouth immediately after the counting and filling is completed. This not only saves the space and cost of configuring a separate capping machine, but also improves production efficiency and hygiene standards.

Control system: The control system of the fully automatic model includes a microprocessor, touch screen interface, photoelectric sensor, contact sensor, visual inspection camera, etc., for the purpose of setting counting parameters, monitoring the production process, adjusting speed and handling faults.

Counting machines can be divided into several main categories according to their design, function and degree of automation. The following outlines several common types of counting machines and their respective advantages and disadvantages, aiming to provide a more comprehensive and differentiated perspective.

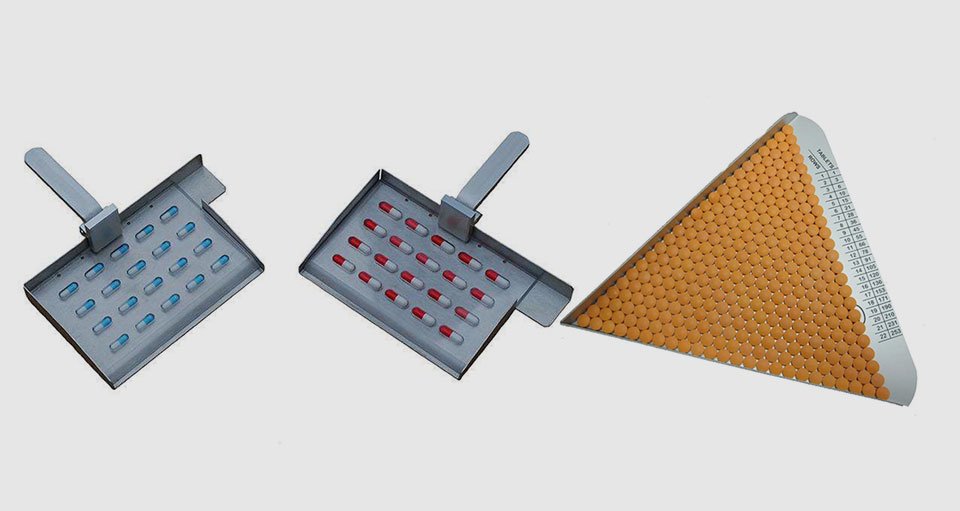

Manual counters are shaped like triangular trays and rectangular trays, with holes all over the surface, and the shape of the material is used as the hole. The principle is very simple. When the material fills the holes on the surface, the excess material is removed, and the number of materials left is the corresponding number of holes.

Its advantages are low cost. Due to its simple structure and low manufacturing cost, it is cheap and easy to obtain; small size and light weight, it can be used in a variety of environments, so it is not restricted by power supply or network; only simple operation is required to complete the counting task, without special training or skills.

The corresponding disadvantage is slow counting speed. Manual operation will inevitably limit the counting speed, and the efficiency is low for fast counting of large amounts of data. Efficiency can only be improved by long-term manual work. Manual operation is easy to fatigue and very easy to cause counting errors.

Manual counting counters are usually used in simple, small, intermittent counting tasks, but in cases where high-speed, large, continuous or complex counting is required, automated counting equipment is inevitably a better choice.

Automatic counting machines are usually small turntable counters or desktop counting machines. The counting system uses electronic components with photoelectric sensing or optical fiber detection. This part is fully automatic. The container replacement after adding and filling requires manual operation.

Compared with fully automatic counting machines, semi-automatic models have compact structures and small footprints, which are suitable for production environments with limited space. At the same time, the procurement cost and maintenance cost are lower. Small or start-up companies can choose this model to save initial investment and reduce maintenance and operating costs.

Semi-automatic counting machines are suitable for small batch or customized production. They can usually flexibly cope with a variety of products and containers of different sizes and shapes. When changing different product types, it is easier to adjust than fully automatic models.

Semi-automatic counting machines provide a compromise solution in balancing cost, efficiency and flexibility. They are suitable for companies with limited budgets and limited space or product diversity.

3 Photoelectric induction type automatic counting machine

The photoelectric induction type tablet capsule counter uses optical sensor technology to achieve non-contact high-speed counting. It can be used to accurately count and fill solid materials such as tablets, capsules, seeds, and soft candies. It is widely used in the pharmaceutical, food, and chemical industries.

The core of the photoelectric induction type tablet counter lies in its photoelectric sensor. Its working principle is that when the particles pass through the sensor area, the light beam is blocked or reflected. After the sensor receives the signal change, it will trigger the count. The entire counting process avoids physical contact and will not damage the material. At the same time, due to the instant response of the speed of light, the counting speed is extremely fast and the accuracy has been significantly improved. For example, the counting accuracy of our Rich Packing photoelectric tablet counter exceeds 99.97%, far exceeding the standards of the industry and peers.

The advantages of Rich Packing photoelectric tablet capsule counting machine are extremely high counting speed. We have various models, distinguished by counting channels, including 4, 8, 12, 16, 32, etc., which can adapt to customers' small, medium and large-scale production needs, with a maximum output of 12,000 bottles per hour.

Stable high precision, using Japanese and German photoelectric sensors, the material detection sensitivity is extremely high, the accuracy exceeds 99.97%, combined with the intelligent waste rejection system to ensure the accuracy of each count, so that the finished product can also achieve 100% accuracy under 24-hour continuous packaging production.

It is very versatile, not only can it handle tablets and capsules of different sizes, shapes, colors and even transparency, but also can handle materials such as soft candies with sticky surfaces. This is mainly due to Rich Packing's research and development innovation in the material distribution system. We use a variety of lifting feeders to achieve even material supply; the dual motor roller silo disperses the materials in the first step; the special cylinder slide and soft candy anti-stacking device ensure that the soft candy is fully dispersed before entering the counting channel; the counting channel uses Teflon coating, and combined with the dimple-shaped surface, the soft candy slides faster on the channel to achieve higher production capacity.

Our photoelectric induction automatic counting filling machine can be integrated with bottle unscrambler, desiccant inserter, cotton plugger, automatic capping machine, labeling and bottle collecting machine system to form a complete packaging production line. With its high precision, high speed and flexibility, we provide accurate and reliable solutions for leaders in various industries, and have won praise from Fortune 500 companies such as GSK, UCB, and USPharma, becoming their long-term partners.

Counting machines are classified in various ways. Facing different needs, each type has its own advantages and more applicable scenarios. Choosing a suitable counting machine depends not only on the nature of the packaging materials to be counted, but also on the production scale, accuracy requirements, cost budget, and future scalability. As a manufacturer with 31 years of experience in the counting and filling machine manufacturing industry, we have rich project experience and numerous solutions for reference. If you have any questions, please contact us.