Cartoning machine is specialized packaging equipment designed to streamline and automate the process of forming cartons, inserting products, and sealing them for retail or distribution. Whether packaging delicate items, liquids, or irregularly shaped goods, a cartoning machine can handle a variety of products efficiently and consistently.

The basic operations of a cartoning machine—carton forming, product insertion, and sealing—provide significant advantages. Carton forming prepares the packaging, product insertion places the item securely within the carton, and sealing ensures the contents are protected and tamper-evident. This automation not only improves the pace and consistency of packaging but also minimizes handling, reducing risks of contamination or damage.

The versatility of cartoning machines means they come in various configurations to fit specific production needs. Here’s a look at the primary types:

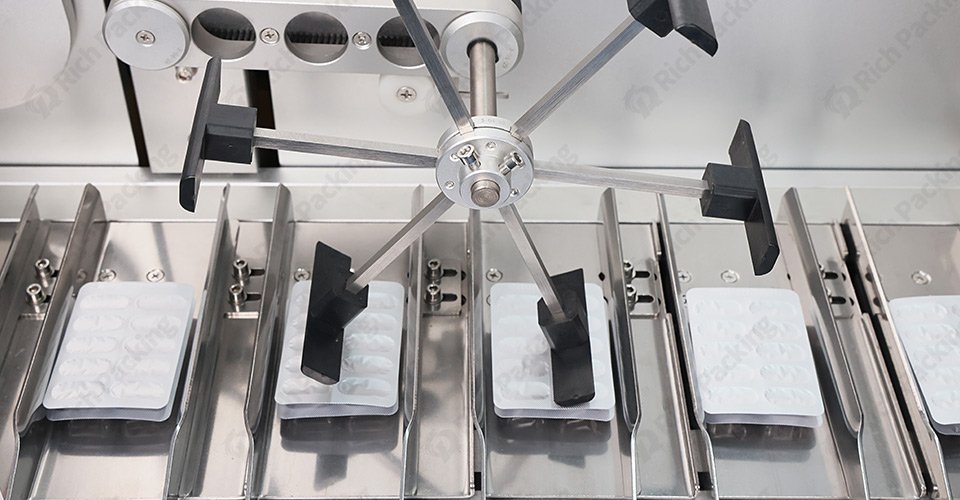

With horizontal cartoning, the machine loads products from the side, making it ideal for items that need to be gently handled or arranged horizontally. These machines are perfect for items like tubes, trays, and other easily stackable products. They also handle fragile or semi-solid items well, ensuring that the product shape and integrity remain intact.

Vertical cartoning machines load products from the top, suitable for items that fit naturally into cartons via gravity, such as pouches, bottles, or irregularly shaped goods. These machines are often used in the food and beverage industry for ease of loading, and they are particularly effective for high-speed lines requiring minimal manual handling.

Cartoning machines also vary in automation level. Fully automated machines provide hands-free operation from start to finish, ideal for high-output facilities needing rapid packaging. On the other hand, semi-automatic machines may require manual assistance for tasks like product feeding or sealing, making them suitable for smaller-scale productions or businesses transitioning into automated solutions without the budget for fully automated systems.

Cartoning machines come equipped with specialized features that make the packaging process both efficient and precise. Let’s break down these core components:

The forming mechanism of a cartoning machine opens and positions each flat carton for product insertion. The technology involved, whether suction cups or precision arms, ensures each carton is accurately shaped and ready for the next stage. This setup reduces the risk of misalignment or structural damage to the cartons, ensuring that every box maintains a high-quality appearance.

Each cartoning machine has a filling system tailored to the type of product it handles. For solid items, such as soap bars or small boxes, the filling system positions products securely within each carton. Meanwhile, machines designed for liquid products include compartments or supports that minimize spillage, ensuring safe and sanitary packaging.

One of the most critical aspects of a cartoning machine is its sealing mechanism. Some machines rely on tuck-in flaps for lightweight products, while others use glue sealing or heat sealing for added strength and durability. This flexibility lets you choose the sealing type that best suits your product, whether you prioritize security, aesthetics, or ease of opening.

User-Friendly Controls

Most modern cartoning machines feature touch-screen panels and programmable logic controllers (PLCs) for intuitive operation. These user-friendly controls simplify production adjustments, allowing you to customize speed, dimensions, and other settings based on the packaging requirements. User-friendly controls also mean faster training for operators, reducing downtime and boosting productivity.

Investing in a cartoning machine can yield numerous benefits for your production line:

Automated packaging drastically increases speed, allowing you to package a large volume of products in a short period. This efficiency not only enhances output but also optimizes labor allocation, reducing the number of operators needed for repetitive tasks.

Cartoning machines provide consistency in every package, maintaining product integrity and appearance. Whether the machine is packing pharmaceutical items or food products, uniform packaging enhances brand reliability, helping you maintain high quality standards across all products.

By automating the packaging process, a cartoning machine reduces the need for manual labor. Operators can focus on other valuable tasks, such as quality control or machinery maintenance, leading to an overall more cost-effective production.

With regulatory standards increasing, particularly in the pharmaceutical and food sectors, safety and hygiene are paramount. Cartoning machines minimize product handling, reducing contamination risks and helping you comply with stringent health regulations.

Various industries rely on cartoning machines for their specific packaging needs. Here are some examples:

Pharmaceutical companies rely on cartoning machines to package products like tablets, syrups, and medical devices. These machines are calibrated to maintain high hygiene standards, ensuring that medicines remain uncontaminated and safely stored until use.

From tea bags to snack bars, cartoning machines package consumable goods safely and attractively. Their sealing options allow food producers to maintain freshness and appeal to consumer demands for hygiene and safety.

For products like lotions, soaps, and perfumes, cartoning machines ensure secure packaging that enhances visual appeal. These items are often fragile or sensitive to environmental factors, and cartoning provides the necessary protection.

Cartoning machines are also used in the packaging of various household and industrial goods, from light bulbs to small hardware items. The packaging is designed to withstand handling and transportation, ensuring products reach consumers intact and ready for use.

When selecting a cartoning machine, several considerations can guide you toward the best choice:

Evaluate how many units per minute the machine can package and whether it aligns with your production goals. A high-speed machine may be crucial if your business deals with large volumes, while a slower machine may be more cost-effective for smaller operations.

Ensure the machine is suitable for your product type and dimensions. For instance, machines designed for pharmaceutical applications may not be ideal for large or bulky items, so consider your product characteristics before making a selection.

Fully automated machines are ideal for high-output facilities, while semi-automated machines may be preferable for smaller or custom packaging runs. Determine whether the machine’s automation level aligns with your production needs and labor capacity.

Cartoning machines vary in size and installation complexity. Make sure to account for the physical footprint of the machine, available space in your facility, and any specific setup requirements it may have.

Choosing the right cartoning machine for your production needs can optimize packaging efficiency, ensure product safety, and enhance brand presentation. By automating the packaging process, you’ll improve productivity, maintain quality standards, and reduce operational costs, keeping you competitive in today’s demanding market. A reliable cartoning machine is more than just a tool—it’s an investment in your business’s future, allowing you to meet industry standards and customer expectations with ease.