In the ever-evolving world of pharmaceutical manufacturing, efficiency and precision are paramount. As you delve into the realm of capsule production, you'll encounter various types of equipment designed to streamline the process. One such piece of machinery that has gained significant traction in recent years is the Semi Automatic Capsule Filling Machine. This innovative device offers a perfect balance between manual operation and automation, providing numerous advantages for pharmaceutical companies of all sizes.

To fully grasp the advantages of a semi-automatic capsule filling machine, it's crucial to delve into its fundamental operation and workflow. These machines are a bridge between manual and fully automated systems, offering a balance of efficiency, precision, and user control. Here's a detailed look at the key steps involved in the operation of a semi-automatic capsule filling machine:

The process begins with loading empty capsule shells into the machine. These shells are usually made of gelatin or a vegetarian alternative like HPMC (Hydroxypropyl Methylcellulose). The capsules are loaded into a designated hopper or tray, which is typically designed to handle a large number of capsules at once. This step is essential for ensuring that the machine can operate continuously without frequent interruptions, thereby enhancing productivity. The hopper's design often allows for easy loading and minimizes the risk of capsule damage during the process.

2. Capsule Orientation

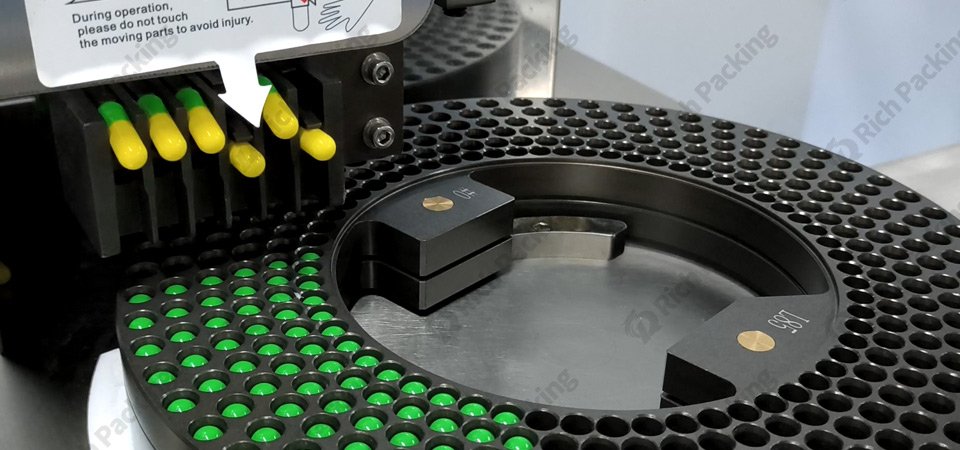

Once the capsules are loaded, the machine's orientation system takes over. This step is critical because the capsules must be positioned uniformly for the subsequent operations. The orientation mechanism uses a series of mechanical movements or vacuum suction to ensure that all capsules are aligned correctly, with the body (the larger part of the capsule) facing downward and the cap (the smaller part) on top. Proper orientation is vital to ensure that the capsules can be separated accurately in the next step.

After orientation, the machine separates the capsules into two halves: the body and the cap. This is achieved through a combination of suction and mechanical action. The machine gently pulls the cap away from the body, keeping both parts in separate positions while ensuring that they remain undamaged. The precision of this step is critical, as any misalignment or damage can result in capsules that cannot be properly filled or closed later in the process.

The most critical part of the process is the precise filling of the capsule body with the intended substance, which could be powder, granules, or pellets. The machine is equipped with a dosing system that ensures the exact amount of material is dispensed into each capsule. This system can be adjusted to accommodate different fill weights, depending on the specific requirements of the product being produced. The accuracy of this step is paramount because it directly impacts the dosage and, consequently, the efficacy and safety of the final product. Many machines offer adjustable settings that allow for the fine-tuning of fill weight and ensure consistency across all capsules.

5. Capsule Closing

Once the capsule bodies are filled, the next step is to securely reattach the caps. The machine gently presses the cap onto the filled body, ensuring a tight fit without compromising the integrity of the capsule. Proper closure is essential to prevent the contents from spilling out and to protect the active ingredients from external factors such as moisture and air. The closing mechanism is designed to apply just the right amount of pressure, ensuring that the capsule remains sealed throughout its shelf life.

The final step in the process is the ejection of the filled and closed capsules. The machine carefully ejects the finished capsules into a collection tray or bin, ensuring they are handled gently to avoid any damage. The ejection system is often designed to minimize the risk of capsule deformation or breakage, which is crucial for maintaining the quality of the product. Once ejected, the capsules are ready for further processing, such as packaging or coating.

Throughout this process, the operator oversees the machine's operation, replenishes materials as needed, and performs quality checks.

Semi-automatic capsule filling machines bridge the gap between manual filling methods and fully automatic systems. They offer a cost-effective solution for small to medium-sized pharmaceutical companies or those producing smaller batches of specialized medications. These machines require a lower initial investment compared to fully automatic systems and are generally easier to operate and maintain.

Another key feature of semi-automatic capsule filling machines is their compact size. These machines typically have a smaller footprint compared to fully automatic systems, making them suitable for facilities with limited space. This compact design also contributes to their portability, allowing for easier relocation within a facility if needed.

1. Improved Efficiency: One of the primary advantages of semi-automatic capsule filling machines is their improved efficiency compared to manual filling methods. With these machines, you can significantly increase your production output without sacrificing quality. Depending on the model and the operator's skill, a semi-automatic machine can fill thousands of capsules per hour, far surpassing what could be achieved through purely manual methods.

2. Enhanced Accuracy: Accuracy is another key benefit of semi-automatic capsule filling machines. These devices are engineered to dispense precise amounts of medication into each capsule, ensuring consistent dosing. This level of precision is difficult to achieve with manual filling methods, where human error can lead to variations in the amount of medication per capsule.

3. Flexibility: Semi-automatic capsule filling machines offer remarkable flexibility. These devices can typically handle a range of capsule sizes, from the smallest (size 5) to the largest (size 000). This versatility allows pharmaceutical companies to produce various products using the same equipment, reducing the need for multiple specialized machines. Additionally, many semi-automatic machines can be easily adjusted to accommodate different fill weights, making them suitable for producing a diverse range of medications.

4. Cost-Effectiveness: Semi-automatic capsule filling machines offer an excellent balance between cost and productivity. They provide a significant increase in output compared to manual methods without the high investment required for fully automatic systems. This makes them an ideal choice for companies looking to scale up production without overcommitting their resources.

5. Easy Cleaning and Maintenance: Semi-automatic capsule filling machines are generally designed with ease of cleaning in mind. Many models feature removable parts that can be quickly disassembled for thorough cleaning and sanitization. This design not only helps maintain a hygienic production environment but also reduces downtime between production runs of different medications.

When comparing semi-automatic capsule filling machines to their fully automatic counterparts, several distinctions become apparent. Automatic Capsule Filling Machines offer even higher production speeds and require minimal human intervention. They can produce tens of thousands of capsules per hour and are ideal for large-scale manufacturing operations. However, they also come with significantly higher upfront costs and may be less flexible when it comes to changing capsule sizes or fill weights.

Semi-automatic machines are suitable for:

- Small to medium-sized pharmaceutical companies

- Companies producing smaller batches or specialized medications

- Businesses with limited production space

- Operations requiring frequent changes in capsule size or fill weight

- Companies looking for a balance between automation and cost-effectiveness

Automatic Capsule Filling Machines are ideal for:

- Large pharmaceutical companies with high-volume production needs

- Businesses producing standard capsule sizes and fill weights in large quantities

- Companies with ample production space

- Operations that prioritize maximum output and minimal human intervention

- Businesses with the capital for significant upfront investment

As you consider implementing a semi-automatic capsule filling machine in your production line, it's important to think about operator training. While these machines are designed to be user-friendly, proper training is essential to maximize efficiency and maintain product quality. Many manufacturers offer comprehensive training programs to ensure that your staff can operate the equipment safely and effectively.

In conclusion, semi-automatic capsule filling machines offer numerous advantages for pharmaceutical companies looking to enhance their production capabilities. From increased efficiency and accuracy to flexibility and cost-effectiveness, these machines provide a valuable middle ground between manual filling methods and fully automatic systems. As you explore options for upgrading your capsule production process, consider how a Semi Automatic Capsule Filling Machine could benefit your operations, potentially leading to improved productivity, product quality, and overall competitiveness in the pharmaceutical market.