The blister packaging machine’s invention is based on the new material development. As the scientist’s research on the PVC and aluminum foil, combined with the electricity and machinery technology, the first invention country is the USA. Because the blister packaging can clearly see the packed product and safe to keep it, it becomes popular all over the world.

The first type is manual operation, it is low production capacity, mainly use in laboratory, pharmacy, hospital, R&D institute etc. this machine can put on the table , so it also call table top blister packaging machine, from the blister forming to sealing, cutting, the whole process need to assist with a operation staff.

The second type is fully automatic packing. From the forming working station to pressing working station, sealing working station, cutting working station no need to use the labor, it will greatly increase the working efficiency and the packaging quality.

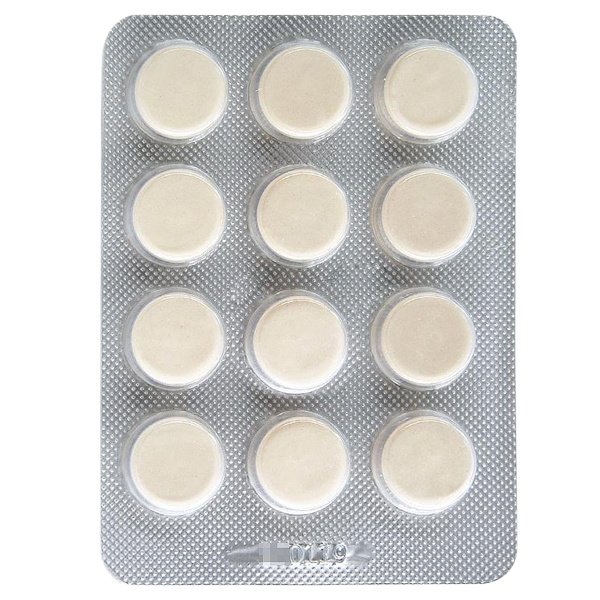

This type of blister packaging use aluminum foil for sealing , PVC for the blister pocket which is hold the tablets or capsules. When you use this material to pack, that means this kind of medicine can be kept in the common environment. 65% of the blister package use this material according to our experience in the pharmaceutical industry. Because this type of packaging cost is more attractive to use.

This packaging way use aluminum foil for two side : the pocket holding and the sealing.

When you consider to use this way to pack, that means this medicine need to avoid the sun, it need to be kept in a closed and a space which it can protect from the sunlight.

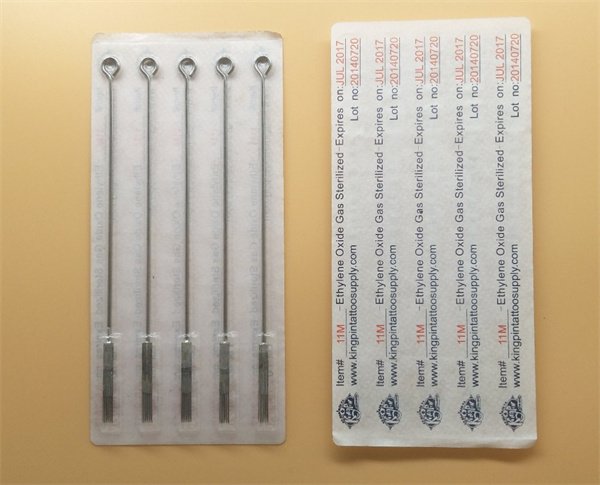

Many commodities are use these material to pack, such as the one time use bistoury, battery, blade etc. It can see the product without tearing the sealing. So it can show to customer with a closed package.

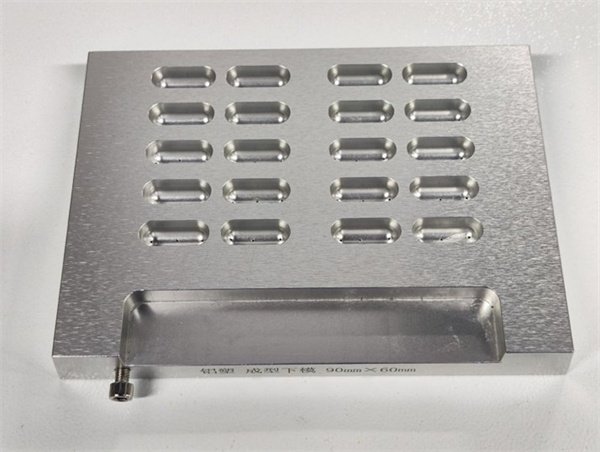

First, the the pvc or aluminum foil will be soften by a high temperature of 130 degree centigrade in the forming working station. In this working station , the softened material will be formed a blister pocket by the compress air.

After the blister pocket is formed, then it will move to a new position to fill the capsule or tablet into the blister pocket.

Then the plate will move to thermo sealing station, in this working station, the capsule or tablet will be sealed with a aluminum foil.

The fourth working flow is the pressing station, in this working station, you can press the batch number, production date on the plate. It can also press the easy tear line on the plate.

The last working flow is the cutting working station, the blister machine will cut the long piece into one intact plate that it will be put into the small box.

5.What Function The Blister Packing Machine Can Perform?

In a word, the machine can pack the capsule, tablet, vape, cosmetics, jam, honey, butter, gummies, disposable syringes, special-shaped objects, injections, vials, and other large-sized products with the pvc and aluminum foil material.

Step 1. Load one roll of material on the blister machine.

Step 2. Start the machine power, make the material move the whole working flow as I mentioned above .

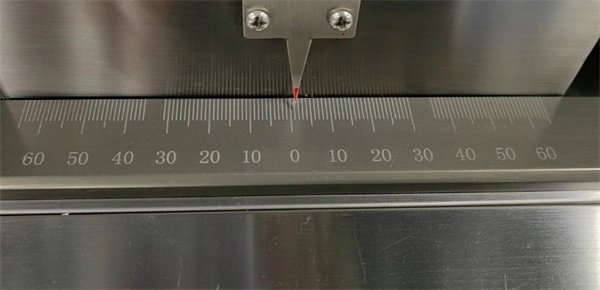

Step 3. Align the working station one by one base on the formed blister pocket.

The RichPacking machine has a ruler below each working station. Use a hand wheel to adjust it if the position is not right.

In the forming working station, it need to heat the pvc or alu foil to make the pocket. It need to keep the temperature on a stable level, if it is too hot, it will spoil the material and affect the forming quality. How we control the temperature? A liquid cooling system will be used in the blister machine. The cooling box will compress the air to make cool water, then the water will flow into the forming working station, then the water will take away the surplus heat, the temperature will be kept in a certain scope.

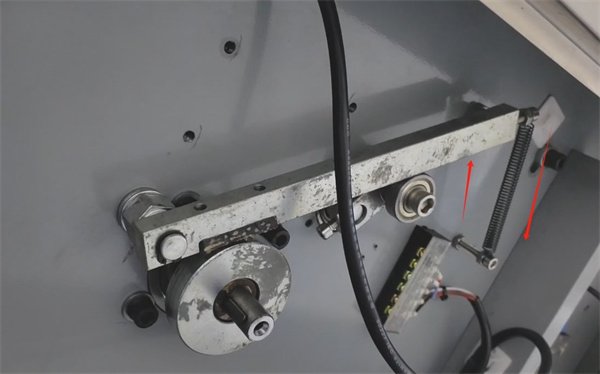

On the sealing working station, there is a roll of aluminum foil loading on. A braking system is controlling the plate stretched tension, so that the material will be tightened on the roller, when it is sealing, the foil or pvc material is exactly covered on the plate, no winkle or surplus material on the plate. As you can see the black roller, it can move upward and downward controlled by a special device with a spring. This braking system will control the foil roll movement according to each working station’s speed.

Front

Back

A.Regular Cleaning

The blister packaging machine will get more and more dust, debris, and residue on the surface after a long time, it you don’t clean, it will affect the performance of the machine. You can a towel or specialized use cloth to clean, you can also use a vacuum cleaner to suck the dust. So you need to clean the blister machine every week or every month according to your production capacity.

B.Lubrication

The gears, chains, bearings, and other mechanical parts will keep running when you operate the machine, which need to oil or lubricate to keep the machine run smooth, need to check periodically. You can refer to the blister packing machine supplier’s operation manual.

C.Consumable Parts

The parts such as sealing bars, cutting blades, and forming tools etc, are easy to wear and damage. If you don’t check it , it will affect the package quality.

D.Safety Check

Inspect safety features such as emergency stop buttons, safety interlocks, and guarding systems , so you can comply with safety standards and regulations. These safety mechanism is very important to ensure that operator can control anytime. Replace the damaged parts or malfunctioning safety components when you found it to prevent accidents or injuries.

E.Training and Education

When the machine is new for your pharmaceutical factory, you need to ask the supplier to train your staff to grip the operation skill. The management need to check your operation staff if he or she is skillful on the machine. Before the trouble occur, the operator need to familiar the solution, so when it happen, it can quickly response.

Qualification

First of all, you need to check the supplier’s qualification. You can check the government issued business license and the certificates of the supplier. You can check if this supplier is registered in the government administration systems. In this license, you need to check when it is established, and the registered capital. Right now China government is supervising the registered capital, the registered capital is equal to the paid in capital.

In China, it has 5 level for the registered capital.

Level 1 is bellow 500000 RMB.

Level 2 is 500000-1millionRMB.

Level 3 is 1 million to 3 million RMB.

Level 4 is 3 million to 10 million RMB

Level 5 is more than 10 million RMB

Our registered capital is 10 million, we are in the level 4.

Besides the business license, you can also check what certificate the supplier gained.

As you can see it, we has gained the CE certificate and the SGS verified supplier certificate .

After-Sale System

Secondly, you need to check if the supplier has a complete after-sale system.

A complete after-sale system include the on-site service center, training standard process. supportive team ,

Right now we have two on site service center, one in Hk, another one in USA.

For the training standard process, we will send you the operation manual for your reference, after your study with the manual , we will train the machine operator , then will take an exam to check if the operator has fully understand our machine’s operation process.

A support team is very important in the after sale system, our team include the supportive staff, senior engineer, our sportive team will answer the common issue you may meet, you can also refer to our social medial, such as youtube, twitter, etc. Our senior engineer has a strong education and working background on the machinery and electricity, this will enable us to offer you a better after-sale experience.

A.Production Requirements

Take the pharmaceutical manufacturer for example, you need to consider these factors: your production capacity, the size of the capsule or tablet, the size of each plate. The packaging material , such as alu-pvc or alu-alu. If you are very clear the above information, will help you choose a right blister machine and a efficient packaging solutions.

B.Cost and Return on Investment (ROI)

Please know, it is not that the more advanced you buy, it is the best for you. You need to match your factory’s actual condition. The final index is the ROI-cost and return on investment. If your product is profitable and the labor cost is high price. The fully automatic blister packing machine is the right one for you. If your country’s labor cost is low, your production capacity no need to produce in a fast speed, you can choose the semi-automatic blister packing machine. At present, you can choose the most cost-effective solution for your budget and production needs, but at the same time, you need to consider the future increased production capacity.

C.Regulatory Compliance

Different country has a standard for different line. In order to meet your local regulation, you need to check the local law and the supplier’s blister machine, if it is meet your requirement. Such as CE, GMP, cGMP,ISO,FDA, etc.