Capsules are a common dosage form widely used in the fields of pharmaceuticals, health supplements, and nutritional supplements. In order to produce high-quality capsule products, capsule filling machines play a crucial role. This guide aims to explore the types, sizes, and filling techniques of capsule filling machines to help you understand how to choose the equipment that best suits your needs and optimize the capsule production process.

Hard-Shell Capsules: They are widely used in the pharmaceutical and health supplement industry due to their ease of manufacturing, low cost, stability, and compatibility with a variety of drug formulations. The investment cost for capsule filling production equipment is relatively low, allowing for rapid and large-scale production.

1.Structure: Composed of two cylindrical shells, a cap and a body, which can be locked together by an internal locking mechanism.

2.Material: Generally divided into "gelatin capsules," "vegetarian capsules," and "enteric capsules."

(1) Gelatin capsules: Mainly made from gelatin (GEL), which is a hydrolysis product of collagen. It is extracted from animal skin, bones, and connective tissues, which are rich in collagen, especially pigskin, cowhide, fish bones, and fish skin. Its hydrolyzed properties and ease of absorption by the human body make it widely used as a raw material for capsule production.

(2) Vegetarian capsules: Made from plant-based cellulose or other materials suitable for vegetarians (such as hydroxypropyl methylcellulose (HPMC)), vegetarian capsules are suitable for vegetarians, those allergic to gelatin, and certain religious groups.

(3) Enteric capsules: Designed to be insoluble in stomach acid, they release the drug once they reach the intestines and are made from materials that can withstand stomach acid, such as methacrylic acid copolymers.

3.Contents: The fill can typically consist of solid powders/granules, micro-pills, and liquids.

Softgels: Commonly used for drugs that are poorly soluble or unstable in solid form, they offer better bioavailability and convenience than traditional tablets or hard capsules. Softgels encapsulate the drug and shell together in a forming machine.

1.Structure: Softgels consist of a sealed, one-piece shell surrounding the contents.

2.Material: Softgels are also made from gelatin, but the formula includes plasticizers (such as glycerin or sorbitol) to make the capsule shell softer and more elastic.

3.Contents: Typically used to package fats, liquids, pastes, suspensions, etc.

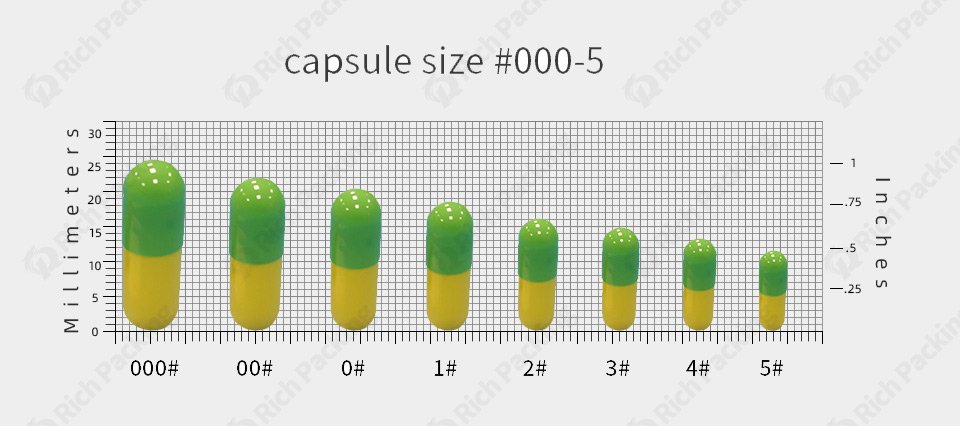

Hard-shell capsules come in a variety of standard sizes, commonly including: 000, 00, 0, 1, 2, 3, 4, and 5. The size of the capsule is denoted by a number, with smaller numbers indicating larger capsules. The following table shows the approximate dimensions and capacities of each capsule size:

|

Capsule Size |

Diameter (mm) |

Length (mm) |

Volume (mL) |

|

#000 |

26.0 |

15.0 |

1.37 |

|

#00 |

23.0 |

15.0 |

1.00 |

|

#0 |

21.0 |

15.0 |

0.75 |

|

#1 |

19.0 |

15.0 |

0.50 |

|

#2 |

17.0 |

15.0 |

0.30 |

|

#3 |

15.0 |

15.0 |

0.25 |

|

#4 |

14.0 |

10.0 |

0.15 |

|

#5 |

11.5 |

10.0 |

0.10 |

The capacity of a hard-shell capsule is not solely determined by its size. Several other factors can influence the amount of material that can be filled into a capsule, including:

·density of the fill material: Denser materials will occupy less volume than less dense materials.

·particle size of the fill material: Smaller particles will pack more tightly into the capsule.

·flowability of the fill material: Free-flowing materials will fill the capsule more efficiently than poorly flowing materials.

·compression properties of the fill material: Some materials can be compressed to increase their density and reduce their volume.

The choice of capsule size is typically based on the following considerations:

desired dosage of the drug: The capsule size should be large enough to accommodate the required amount of drug.

properties of the fill material: The capsule size should be compatible with the density, particle size, flowability, and compression properties of the fill material.

desired filling method: Some capsule sizes are more suitable for certain filling methods than others.

desired appearance of the product: Larger capsules may be more visually appealing for certain products.

In addition to the standard sizes listed above, custom capsule sizes can also be manufactured to meet specific requirements.

Capsule filling machines are mechanical devices specifically designed to fill solid particles, powders, or liquid ingredients into hollow capsule shells, commonly used in the pharmaceutical industry and, with the popularization of health concepts, also widely used in the manufacture of dietary supplements and other health products.

Since the invention of automatic capsule filling machines, with the continuous innovation of industry technology, there are now various models of capsule machines to meet different production needs. Different types of capsule filling machines include: manual, semi-automatic, and fully automatic capsule filling machines.

This is the most basic compact type of capsule filling machine. Manual capsule filling machines are generally used for filling medications or powdered substances into capsules. They are very useful for small-scale production, research, and clinical trials. They are suitable for individual use, small-scale production, or laboratory applications. Due to their simplicity and low cost, manual filling machines are commonly used during the initial stages of dietary supplement or drug development.

Semi-automatic capsule filling machines are devices that fall between manual operation and fully automated production. They combine ease of operation with a certain degree of automation. These machines are typically used by small to medium-sized pharmaceutical companies, especially those with specific production efficiency requirements but without the investment capacity for a fully automated production line. Working Steps and Principles:

1) Capsule Positioning and Separation: First, empty capsules are sorted and placed into capsule trays and separated to prepare for filling.

2) Automatic Material Filling: The operator places the separated capsule body tray onto the material filling station, where it automatically fills with the desired powder or granular material.

3) Capsule Closure: After filling, the capsule tray is placed on the automatic capsule closure station to complete the sealing process.

4) Ejection and Sorting: Closed capsules are then ejected and sorted for the next steps, such as packaging or quality inspection.

The working principle of semi-automatic capsule filling machines relies on the operator’s manual filling steps, which somewhat limits production speed but provides greater flexibility and direct control over the filling process.

Fully automatic capsule filling machines play a crucial role in pharmaceutical capsule encapsulation. They ensure the integrity and precision of medication capsule filling production and significantly enhance production efficiency. These machines handle the entire process, from sorting and separating empty capsules to precisely controlling the dosage of filling materials and screening defective capsules, all the way to capsule closure—without any manual intervention. This automation saves labor and boosts production efficiency.

Here are the working steps and principles of fully automatic capsule filling machines:

Empty capsules are placed in the capsule hopper. The main board moves up and down, allowing capsules to enter the capsule guide through gravity. Horizontal forks then position the capsules with the cap facing up and the body facing down, entering the upper and lower modules. Vacuum suction separates the capsule body from the cap. The module then moves to the powder material filling station.

Sensors control the pneumatic butterfly valve above the powder material hopper, continuously adding powder material to the filling metering disc.The material height in the metering disc remains constant. While the metering disc intermittently rotates, multiple filling rods sequentially compact the powder material into the metering disc holes.At the filling station, the powder material column is pushed into the capsule body.

At the rejection station, photoelectric sensors detect whether the capsules are intact and contain sufficient filling material.Any defective capsules are automatically rejected.

Qualified capsules move to the closure station, where the upper and lower modules align.

The cap is pressed onto the body, completing the closure process.

Locked capsules are ejected, completing the entire filling process.

Selecting an appropriate capsule filling machine requires careful consideration of various factors. Each model has unique advantages and limitations, so the choice should align with specific production needs and financial constraints. For example, manual and semi-automatic machines are cost-effective and suitable for start-ups or small-scale production. Conversely, fully automatic machines aim to improve efficiency and precision, meeting the demands of large-scale manufacturers while adhering to strict European and American quality standards.

As technology advances, the performance of manual, semi-automatic, and fully automatic capsule filling machines continues to improve, ensuring that manufacturers of all sizes can obtain reliable equipment capable of delivering high-quality results to meet the growing market demands.