Capsule filling machine, it also known as capsule filler machine or capsule filler, is an indispensable part in the pharmaceutical field. It is a mechanical equipment specially used to fill solid granule, powder or liquid ingredients into hollow capsule shells. It is usually used in the pharmaceutical industry and now is widely used in the manufacture of dietary supplements and other health products based on the popularity of health perspectives. This article will explore these models and their features in depth, hoping to bring you useful reference value based on your budget, production scale or site conditions.

Since the invention of the , with the continuous innovation of industry technology, there are now a variety of capsule machine models, which have been updated to adapt to different production needs.

Following are the different types of capsule machines

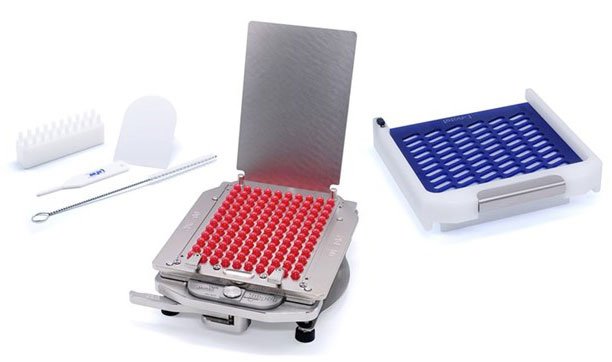

This is the most basic compact machinery capsule filling, suitable for small production or home workshops or laboratories. Due to their simplicity and low cost, manual filling machines are commonly used by people in developing countries in the early stages of starting a business or in the early stages of drug development. It is determined by poor filling accuracy and extremely low production efficiency.

The semi-automatic capsule filling machine is a more advanced equipment than the manual filling machine. It not only improves the production rate, but also reduces the waste of drugs caused by manual labor.

(1) Production efficiency: It can automatically complete the steps of capsule separation, filling and sealing, so the production efficiency is much higher than that of a manual filling machine.

(2) Easy operation: The operation and maintenance of the semi-automatic making capsule machine are simpler than that of the fully automatic model, and even non-skilled operators can use it easily.

(3) Versatility: Compared with manual capsule machines, the dosage of filling powder and granules can be accurately controlled by configuring different automatic feeders and stirring heads;

In addition, we have changed the situation that the semi-automatic capsules making machine could not fill liquid before by developing capsule liquid filling machine semi automatic with a special liquid feeding pump.

(4) Flexibility: The production capacity ranges from a few thousand capsules to 40,000 capsules per hour, so it can meet the needs of both small batch production and medium-scale production.

(5) Moderate cost: Compared with fully automatic encapsulating machines, semi-automatic models have lower purchase costs and are more suitable for start-up companies or companies with limited budgets.

The fully automatic capsule filling machine has the highest efficiency in production and can automatically complete the basic steps of hard-shell capsule sowing, ingredient filling, rejecting unqualified products, sealing, capsule output, etc. Our NJP model type machines also have a vacuum powder feeder, vacuum capsule shell loading machine, printing and other functions that are more convenient for customers to use.

If you want to help your business develop rapidly or the pharmaceutical industry in your country and region meets the requirements of cGMP, and your company requires production line machines to meet the requirements of Industry 4.0 (enable production equipment to support data upload and download), then a fully automatic capsule machinery. It is the first choice of pharmaceutical companies.

Let’s explore further about the fully automatic encapsulation machine and its advantages:

(1) The production speed of the fully automatic encapsulation machine is its biggest selling point. It can produce tens of thousands to hundreds of thousands of tablets per hour. This is a capacity that manual and semi-automatic equipment cannot reach.

(2) The fully automatic filling machine capsules model type has a very high accuracy, exceeding 97%, which is particularly important in medium and large pharmaceutical factories that require consistent product quality.

(3) It can greatly improve the automation of your pharmaceutical production line. Through advanced devices such as automatic material feeders, automatic production detection functions, automatic door control alarm functions, and Siemens PLC, while improving safety, human labor savings are achieved, thereby reducing production costs and improving production efficiency.

Choosing which filling capsules machine is not a simple matter, each model has its own advantages and disadvantages. The choice needs to be made based on your own production needs and actual budget. For example, manual and semi-automatic encapsulating machines are relatively low-cost and more suitable for early-stage startups or small-scale production; while fully-automatic filling machines have higher efficiency and accuracy in large-scale production and comply with European and American standards. With the advancement of technology, whether it is manual, semi-automatic or fully automatic filling encapsulation machines, their performance is constantly improving to meet the increasing market demand.

Browse our website content to learn about Rich Packing. As a leading manufacturer of capsules filler machines in China, we have been committed to providing innovative, efficient and reliable pharmaceutical production equipment for the pharmaceutical manufacturing industry. With more than 30 years of overseas commissioning experience and comprehensive services, Rich Packing's capsule filling machines have been widely recognized by customers and users in terms of safety, efficiency, ease of operation and long-term reliability.

Rich Packing's product line covers capsule filling semi-automatic and fully-automatic machine models, which can meet the needs of different scales of production. In order to ensure product quality, all machines undergo strict quality inspection before leaving the factory. We provide comprehensive after-sales services, including installation guidance, operation training, maintenance and timely technical support, to help customers maximize the production efficiency of their equipment. Therefore, we have won the trust and praise of our customers.

In general, as China's leading capsules machine manufacturer, Rich Packing not only provides high quality products, but also provides efficient solutions and high quality services. If you are considering purchasing a capsule filling machine, you may wish to get in touch with us , just send your requirements and leave the rest to us.