In the pharmaceutical industry, High speed tablet press have become indispensable key equipment. With the rapid development of the pharmaceutical industry, pharmaceutical companies have increasingly higher requirements for production efficiency, product quality and accuracy. High-speed tablet presses meet the stringent needs of modern pharmaceutical production with their high efficiency, precision and stability. This article aims to comprehensively introduce the importance of high-speed tablet presses in the pharmaceutical industry and its wide range of application scenarios, and understand its working principle and functional structure to help everyone better understand the core role of this advanced equipment in modern pharmaceutical production.

As the name suggests, the biggest feature of high-speed tablet press is the high efficiency brought by high speed. Compared with traditional tablet pressing equipment, high-speed tablet presses can produce thousands or even tens of thousands of tablets per minute, producing more tablets per unit time, significantly improving production efficiency. For pharmaceutical companies that produce drugs on a large scale, the high degree of automation of high-speed tablet presses reduces manual operations and production costs, which can significantly shorten the production cycle and improve production energy efficiency to meet the growing market demand for drugs.

The high-speed tablet press can accurately control the thickness, powder content and hardness of each tablet during the tableting process to ensure that the ingredients of each tablet are uniform, avoid unstable drug effects caused by uneven weight or insufficient hardness, and reduce the impact of human factors on influence on drug quality and improve drug safety.

In addition, the high-speed tablet press is equipped with an advanced monitoring and detection system, which can monitor various parameters in the production process in real time, detect and correct deviations in production in a timely manner, and accurately classify tablets that do not meet production requirements when discharging. Waste removal further improves product quality and ensures the efficacy of tablets.

Although the initial investment of a high-speed tablet press is high, its efficient production capacity and stable product quality can help companies save a lot of manpower, material resources and maintenance costs. The high-speed tablet press reduces the scrap rate and rework rate during the production process, thereby reducing production costs. Functions such as automated safety monitoring, intelligent lubrication and mold self-cleaning also greatly reduce equipment maintenance costs. In the long run, the use of high-speed tablet presses can bring considerable economic benefits and healthy growth to enterprises.

As the pharmaceutical market continues to change, pharmaceutical companies need to produce drugs of different types and specifications. The versatility and flexibility of high-speed tablet presses enable them to quickly adjust production parameters to adapt to the production needs of different pharmaceuticals. Whether you are producing large batches of a single variety of tablets or small batches of multiple varieties of tablets, high-speed tablet presses are capable of the job.

In the production of oral solid dosage forms, pill tablet press machine are one of the most common pieces of equipment. Tablets are widely used in various therapeutic fields due to their advantages such as portability, convenience in taking, and accurate dosage. The high-speed tablet press can efficiently and stably produce various tablets in large quantities and is an important equipment for pharmaceutical companies to produce oral solid preparations.

As people's health awareness increases, the market demand for health care products continues to grow. Health care products come in various forms, and tablets are one of the important forms. The high-speed tablet press is not only suitable for the production of pharmaceuticals, but also for the production of various vitamins, mineral tablets and other health products, and can meet the high standards of health product production.

Some drugs have special requirements for the production environment and process, such as sustained-release tablets, controlled-release tablets, etc. The precision control system and advanced technical means of the high-speed tablet press can meet the production needs of these special drugs and ensure the efficacy and safety of the drugs. Especially during public health emergencies, large quantities of emergency medicines are quickly produced to meet demand.

The working principle of a high-speed tablet press can be summarized as the following steps, which mainly include raw material transportation, measurement and distribution, compression molding, demoulding and collection, etc. The following is an introduction to its detailed working principle:

The feeding system is one of the key parts of the high-speed tablet press. Its main function is to feed uniformly mixed powder or granular drugs into the mold. The feeding system usually consists of a hopper stirring device, a metering plate and a forced feeder. The powder in the hopper is kept uniform through the stirring device to avoid uneven tablet composition due to powder deposition or stratification. The precise measurement of the metering plate and the forced feeder feed the powder into the mold accurately and quantitatively, ensuring that the amount of raw materials for each tablet is accurate.

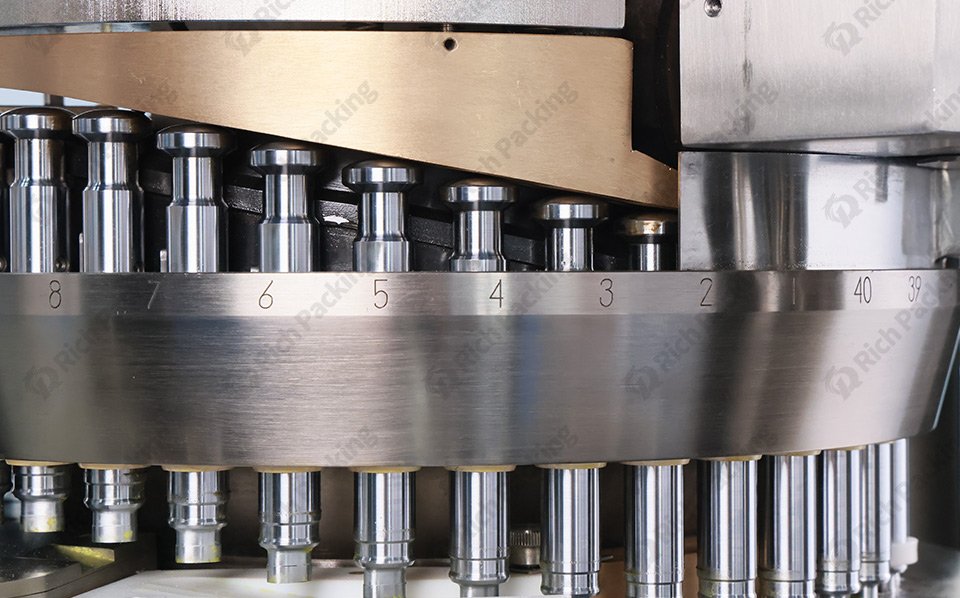

The compression molding system is the core of the high-speed tablet press, and its main task is to compress the powder in the mold into shape. The tableting system consists of upper punch, lower punch and mold. The tableting process is divided into the following steps:

- Filling: The lower punch reaches the lowest position, and the powder enters the mold through the feeder.

- Pre-pressing: The upper punch and the lower punch move to the center of the mold at the same time to pre-press the powder, discharge excess air, and initially form.

- Main pressure: The upper punch and lower punch further apply pressure to make the powder pass through high pressure and compress it into tablets.

A high-speed tablet press is composed of multiple systems and components, and each part works closely together to ensure the smooth progress of the tableting process. The following is a detailed introduction to the main functional structure of the high-speed tablet press:

The control system is the "brain" of the high-speed tablet press, responsible for managing and coordinating the operation of various components. Modern high-speed tablet presses are usually equipped with advanced PLC (programmable logic controller) and HMI (human machine interface), which can realize fully automatic control and real-time monitoring of the tableting process. The operator sets production parameters through HMI, such as tableting speed, pressure, filling volume, etc., and the control system accurately controls the operation of each component according to the set parameters.

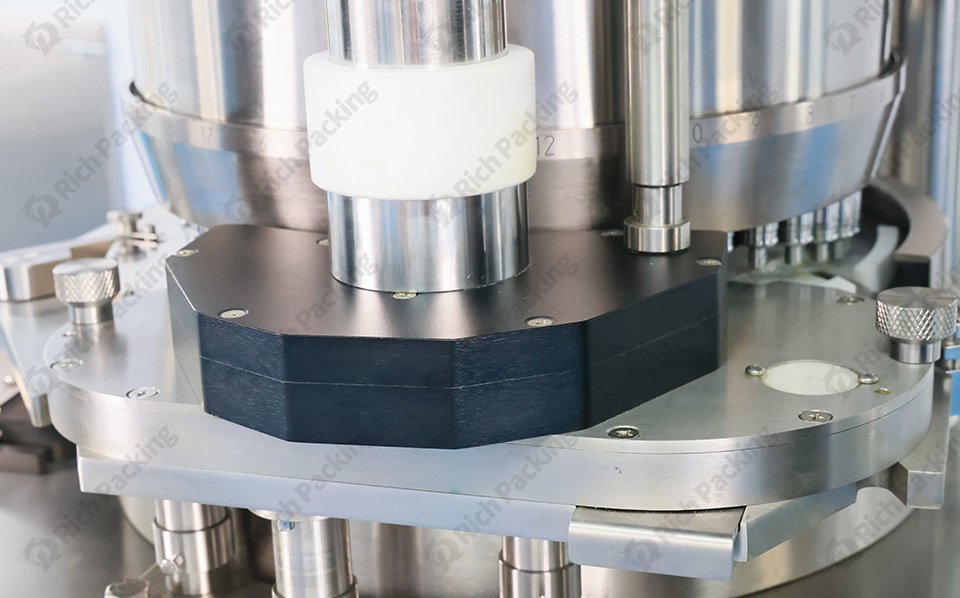

The feeding system is the key to ensuring uniform distribution and quantitative filling of medicinal powder. The feeding system includes a hopper stirring device, a metering plate and a forced feeder. The hopper is used to store the medicinal powder, and the stirring device keeps the medicinal powder uniform and avoids sedimentation or stratification. The feeder feeds the powder into the mold quantitatively, ensuring that the composition of each tablet is consistent.

The tablet press system is the core part of the high-speed tablet press, including upper punch, lower punch and mold. The upper punch and the lower punch exert pressure on both sides of the mold to compact the powder into tablets. The design and manufacturing accuracy of the tableting system directly affects the quality of the tablets. Therefore, the tableting system of a high-speed tablet press usually uses high-strength materials and precision processing technology.

The tablet ejection system is responsible for removing the formed tablets from the mold.

The lubrication system is used to reduce the friction between moving parts and ensure the normal operation of the equipment. The lubrication system usually includes a lubrication oil pump, a lubrication oil tank and a lubrication pipeline. The lubricating oil pump delivers lubricating oil to various components that need lubrication, the lubricating oil tank stores the lubricating oil, and the lubrication pipeline distributes the lubricating oil to various lubrication points. The high-speed tablet press can automatically control equipment distribution, lubrication and maintenance operations through the integrated PLC system.

The detection system is used to monitor various parameters during the tableting process, such as tablet weight, hardness, thickness, etc. Detection systems usually include pressure detectors, material detectors and reject detectors. The detection system can provide real-time feedback on detection results, promptly discover and correct deviations in production, and ensure product quality.

High-speed automatic tablet press machine has become an indispensable and important equipment in the pharmaceutical industry due to its high efficiency, accuracy and stability. It not only significantly improves production efficiency and ensures product quality, but also can meet diversified production needs and brings huge economic benefits to pharmaceutical companies.