Blister packing machines play a crucial role in the packaging industry, particularly in the pharmaceutical sector. It is important to maintain the blister packed capsule or tablet in good condition without any damage. In this article, we'll delve into the development, applications, working principles, types, market trends, and more related to blister packing machines.

After the reading, you will unlock the expertise and knowledge in blister machine.

Blister packing machines from how to make it to become a commercial product. In the mid-20th century, the strong demand for advanced packaging led industry experts and R&D researchers to start considering a product that could really increase efficiency in the pharmaceutical industry. The early models were rudimentary, focusing primarily on basic functionality. As the technology and materials development, the blister machine has made a big progress in the design.

The development of blister machines has been driven by the pharmaceutical industry's stringent requirements. Innovations such as thermoforming and cold forming have enhanced the machines' capabilities, allowing for more precise and reliable packaging. Today, modern blister packing machines are equipped with sophisticated features like automated feeding systems, high-speed production capabilities, and advanced quality control mechanisms.

Blister packing machines are widely used across various industries, but their primary application is in the pharmaceutical sector. They are designed to protect tablets, capsules from malicious or nature environmental damage.

In addition to pharmaceuticals, blister packing machines are also used to pack the jam, cosmetic, perfume, vape, medical scalpel, ball pill, inject vaccine, etc. The electronics industry utilizes these machines to package small components, while the consumer goods sector uses them for items like batteries, razors, and stationery.

The working principle of a blister packing machine involves several key steps. These machines can be categorized into two main types: heat forming for pvc-alu blister packing, and room temperature forming for alu-alu blister packing.

1. Material Feeding: A roll of plastic film or sheet is fed into the machine.

2. Heating: The plastic film is heated to a pliable state.

3. Forming: The heated film is then molded into cavities using a forming die with a compressed air blowing.

4. Product Loading: Products are placed into the formed cavities either manually or automatically.

5. Sealing: A lidding material (usually aluminum foil) is placed over the cavities and sealed using heat and pressure.

7. Indentation: The indentation is optional for the blister machine, this process is to press the bath number and production date on the plate.

6. Cutting: The blister packs are cut into individual units.

1. Material Feeding: A roll of aluminum-based laminate is fed into the machine.

2. Forming: The laminate is pressed into cavities without heating.

3. Product Loading: Products are placed into the formed cavities.

4. Sealing: A lidding material (usually plastic film) is placed over the cavities and sealed using heat and pressure.

5. Cutting: The blister packs are cut into individual units.

Blister packing machines can be classified into several types based on their design and functionality:

1. Rotary Blister Packing Machines: These machines use a rotating drum for forming and sealing the blisters. They are suitable for high-speed production.

2. Flat-Plate Blister Packing Machines: These machines use flat plates for forming and sealing. They offer more precise control and are ideal for packaging delicate products.

3. Roller-Type Blister Packing Machines: These machines use rollers for forming and sealing and are known for their high efficiency and speed.

4. Continuous Motion Blister Packing Machines: These machines are designed for continuous operation and are used for large-scale production.

China is a major player in the global blister packing machine market. The country's manufacturing capabilities, coupled with advancements in technology, have positioned it as a leading supplier of these machines. However, the advanced blister machine is produced in USA and Europe. But China blister machine is highly competitive in the price and it’s sophisticated design. The market in China is in keen competition, which make the manufacturer focus more on the innovation and the quality. Chinese blister packing machines are known for the high performance cost ratio, making them an attractive option for pharmaceutical industry decision maker at the same time, no need to worry about the packaging quality.

| Year | Export Value (USD Million) | Export Volume | Key Influence |

| 2019 | 1000 | Stable | Steady demand from pharmaceutical and food industries. |

| 2020 | 1100 | Increase | Surge in demand due to COVID-19 pandemic, particularly for pharmaceutical packaging. |

| 2021 | 1300 | Rebounded Strongly | Recovery of global economies and continued high demand in the pharmaceutical sector. |

| 2022 | 1450 | Further Growth | High demand from pharmaceuticals and increased demand from electronics and consumer goods industries. |

| 2023 | 1600 | Continued Growth | advanced packaging solutions with sustainability and automation technologies. |

The cost to manufacture a blister packing machine depends on several factors, including the type of machine, its capacity, and the level of automation. Key cost components include:

1.Raw Materials: The cost of materials such as stainless steel, aluminum, and plastic films.

2. Labor: Skilled labor is required for assembly, testing, and quality control.

3.Technology: Investment in advanced technology and machinery for precision manufacturing.

4. Research and Development: Continuous innovation and improvement efforts.

5. Compliance: Follow the industry standards and regulations.

Blister packaging machines are widely regarded as the best option for the pharmaceutical industry due to several reasons:

1. Protection: They provide excellent protection against moisture, light, and contamination.

2. Convenience: Blister packs are easy to handle, store, and transport.

3. Compliance: They facilitate compliance with dosage and regulatory requirements.

4. Tamper-Evident: Blister packs are tamper-evident, enhancing product safety.

While blister packing machines are highly effective, they are not the only option. Other packaging methods, such as strip packaging and bottle filling, are also used in the pharmaceutical industry. The decision on choosing what kind of packaging method depends on the consumer’s and expert’s recognition, the government’s supervision legal system.

After purchasing a blister packing machine, there are several ongoing costs to consider:

1. Maintenance: Regular maintenance is essential to ensure the machine operates efficiently and has a long lifespan.

2. Spare Parts: Replacement of parts that are closed to lose the normal function.

3. Training: Training the staff who is going to use this blister machine.

4. Energy Consumption:The cost of electricity to run the machine.

5. Consumables: Materials such as plastic films and foils used in the packaging process.

There is a common misconception that Chinese blister packing machines are of lower quality compared to those from other countries. However, this is not necessarily true. Many Chinese manufacturers has a strict quality control system to ensure their product quality. The key is to select a reputable supplier with a proven track record.

Chinese manufacturers often offer good price with good quality. By conducting thorough research and due diligence, businesses can find reliable Chinese suppliers that provide machines with excellent performance and durability.

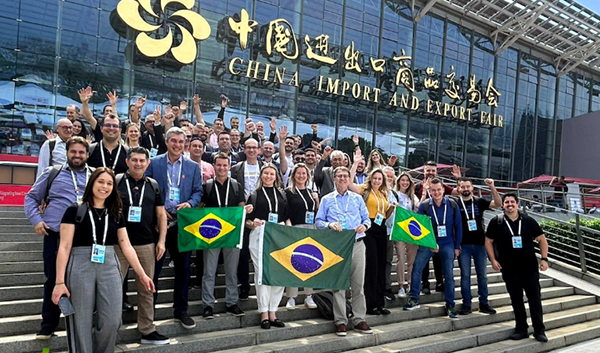

The Canton Fair, also known as the China Import and Export Exhibition Fair. It is an excellent platform to find reputable blister packing machine suppliers. It is one of the most comprehensive fairs in the world, attracting exhibitors and buyers from various industries. At the Canton Fair, you can:

1. Meet Suppliers: Interact directly with manufacturers and suppliers.

2. See Demonstrations: Observe live demonstrations of blister packing machines.

3. Compare Products: Compare the features, quality, and prices of different machines.

4. Negotiate: Discuss terms and negotiate deals directly with suppliers.

To ensure a blister machine supplier is qualified, consider the following steps:

1. Reputation: Research the supplier’s reputation and read customer reviews.

2. Certifications: Verify if the supplier has relevant certifications and complies with industry standards.

3. Experience: Assess the supplier’s experience in manufacturing blister packing machines.

4. References: Ask for references and contact previous customers to inquire about their experiences.

5. Factory Visit: If possible, visit the supplier’s address to audit and verify customer’s real condition.

6. Quality Control: Ensure the supplier’s quality control are effective and continous.

In a word, blister machines are a must have machine in the packaging industry, particularly for pharmaceuticals. Understanding their development, applications, working principles, types, and market dynamics can help decision makers keep an updated information. With careful consideration and research, finding a reliable supplier, even in competitive markets like China, is entirely feasible.