Maintaining a tablet compression machine, also known as a tablet press machine or automatic tablet press machine, is crucial for ensuring consistent and efficient production of tablets. Keep doing the maintenance will make the machine run longer , at the same time, the tablet quality will remain consistently. This guide will help the user have a overview on how to maintain the tablet pressing machine. We'll cover which parts require attention during daily operation, the regular tasks that need to be performed after a certain period, how frequently maintenance should be conducted, and a step-by-step guide on maintaining the tablet pressing machine.

Daily operation of a tablet compression machine involves monitoring and inspecting various components to ensure smooth functioning. Here are the key parts that need your attention:

1. Turret

The turret holds the tooling (dies and punches) and rotates to compress the powder into tablets. Check for any signs of wear or damage, as this can affect tablet quality and machine performance.

2. Punches and Dies

Inspect the punches and dies for any signs of wear, chipping, or misalignment. Worn or damaged tooling can lead to tablet defects such as capping, lamination, or variations in tablet weight.

3. Lubrication System

Ensure that the lubrication system is normally working, and that all the parts required to lubricate are in good condition. Insufficient lubrication can lead to increased wear and tear. If the lubricant is not enough, the moving parts will be in the possibility of damage.

4. Compression Rollers

Check the compression rollers for smooth operation and any signs of wear. Worn rollers can affect the compression force and, consequently, the quality of the tablets.

5. Feeder System

Ensure that the feeder system is delivering powder consistently and evenly. Any blockage or inconsistency in the feed can lead to uneven tablets.

6. Electrical Components

Inspect the electrical components, including sensors and control panels, for proper operation. Any issue on these components will affect the normal production process.

7. Safety Guards

Check the safety guards are running without any problem. Safety must treat it as the most important thing , so it can avoid the unnecessary loss.

After a certain period of operation, more thorough maintenance tasks should be performed to ensure the longevity and efficiency of the tablet press machine. These tasks include:

1. Cleaning

Periodically clean the machine surface’s dust, powder etc. will keep it always in good performance status. Use appropriate cleaning agents that do not damage the machine's components. Please use the soft cleaning agents , so it won’t destroy the machine’s components.

2. Tooling Inspection and Replacement

The punches and dies need to be inspected every month, if you found it is worn , you need to replace it. This prevents tablet defects and maintains production quality.

3. Calibration

After a certain period of operation, the machine needs to re-align to keep it normal.

Calibration involves adjusting the compression force and other parameters.

4. Lubrication

Ensure that all moving parts are lubricated enough. Replace the lubricants as per the manufacturer's recommendations to prevent wear and tear.

5. Electrical System Check

Please make sure that the cable is not damaged, the sensors can run normally. Replace any faulty components to prevent machine downtime.

6. Bearing and Gear Inspection

If you found the bearing and the gear are not as good as the usual time, add lubricant or replace it.

How many times to have the machine maintained? You need to carefully refer to the tablet press machine manufacturer’s operation manual. Generally, daily inspections and cleaning should be performed, while more thorough maintenance tasks should be carried out weekly, monthly, or quarterly.

Daily Maintenance

- Visual inspection of all components

- Cleaning of surfaces and removal of powder residues

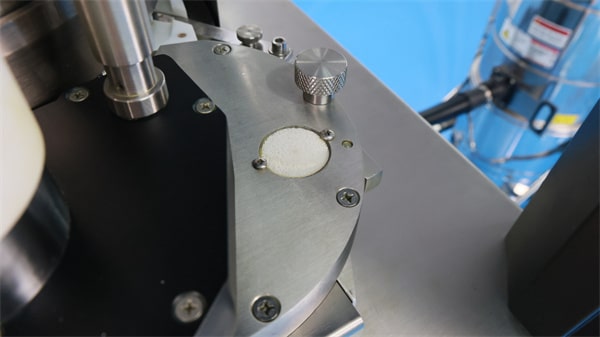

Another important lubrication is the grease for the bear and gear. If you run the machine with a consecutive 24 hours, you need to have the grease on it every two days. For the common operation, a weekly grease is ok. As you can see the following photo, just pull the handle, the grease will be added on.

Weekly Maintenance

- Detailed inspection of punches, dies, and other tooling

- Checking the feeder system for blockages

- Inspecting the electrical components

Monthly Maintenance

- Check If the moving part need to be adjusted

- Lubrication of moving parts

- Inspection of compression rollers and bearings

Quarterly Maintenance

- All-Sided inspection and cleaning

- Replacement of worn parts

- Checking and replacing lubricants

Proper maintenance of a tablet press machine involves several steps. Here is a step-by-step guide to help you maintain your machine:

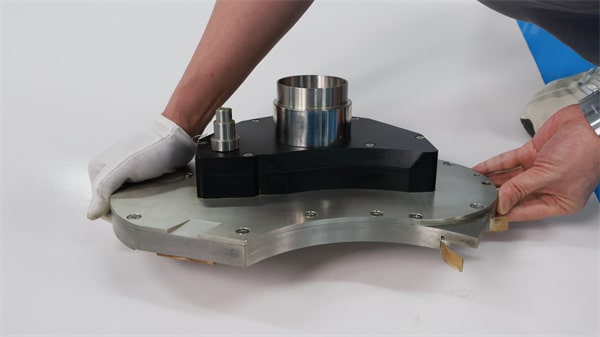

Step 1: Safety First

The first step is that you need to shut down all the electric power connected to the machine. Wear a glass and a glove is the right thing to do, these protective stuff will add more safety for operator.

Step 2: Cleaning

Clean the machine thoroughly. Remove any powder residues using a brush or vacuum cleaner. Use a suitable cleaning agent for the machine's surfaces, ensuring not to damage any components.

Step 3: Inspect Tooling

Remove the punches and dies and inspect them for wear or damage. Clean them with a suitable solvent and dry them thoroughly. Replace any tooling that is going to be not in a good performance.

Step 4: Lubrication

The manufacturer will give a detailed instructions on the lubrication, you need to get and read the manual before you do it. Ensure that the lubricating system work well and that there are no blockages.

Step 5: Check Compression Rollers

Inspect the compression rollers for smooth operation. Clean them and check if it can maintain a safe running. Replace the parts it’s “life” is going to be the end.

Step 6: Feeder System Maintenance

Inspect the feeder system for blockages or inconsistencies. Clean the feeder and ensure it is delivering powder uniformly.

Step 7: Electrical System Inspection

Check the electrical parts such as the integrated control panels and the electrical sensors.

Tighten loose parts and replace it when is no in the normal status or it is going to be dangerous.

Step 8: Calibration

Calibrate the machine to ensure the machine will produce the setting dose and intact tablet. Adjust the compression force and other parameters as needed.

Step 9: Bearing and Gear Check

Inspect the bearings and gears for wear. Put the grease on them or replace them according to their working hours.

Step 10: Final Inspection

A check list need to have to check all the task you have done. Run the machine for a short period to check for any issues.

Step 11: Documentation

Document all maintenance activities, including inspections, replacements, and calibrations. This helps in tracking the machine's maintenance record and planning the next maintenance.

Conclusion

Maintaining a tablet compression machine is essential for ensuring consistent tablet quality and prolonging the machine's lifespan. By paying attention to daily operations, performing regular maintenance tasks, and following a systematic maintenance schedule, you can keep your tablet press machine in optimal condition. Whether you are dealing with a manual, semi-automatic, or automatic tablet press machine, these maintenance practices will help you achieve reliable and efficient production.

Remember, regular maintenance not only prevents unexpected downtime but also enhances the safety and efficiency of your tablet compression machine.

By keeping the maintenance with the best practices, you ensure that your tablet compression machine operates well even in the full commitment status, producing high-quality tablets consistently. This comprehensive approach to maintenance will help you avoid common fault and ensure that your machine remains a reliable asset in your production process.