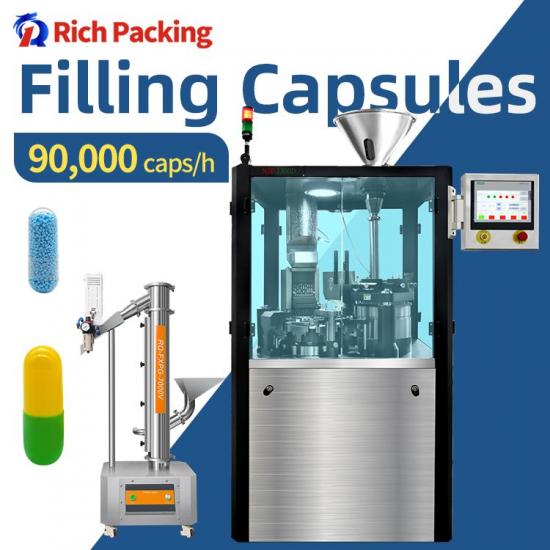

Automatic Capsule Filling Machine Powder

The D-Model 1500d capsule filling machine for using to fill powders, particles and other materials into a hollow capsules, only for the hard shell capsules. The size ofcapsules ares from 000,00,0 to material 5 size. 1500D can be used in the pharmaceutical industry, pharmacy subpackage, all kinds of enterprises and universities to produce Hard capsules.

*** Applications

*** Technical parameter

| Name |

Fully automatic powder filling machine |

|

Production capacity |

90000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size of machine |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

*** Operation mechanism of automatic capsule powder filling machine

Ten working stations for filling capsule size 000 :

--------------------------------Capsule feeding

--------------------------------Capsule separating

--------------------------------Free station or pellet device

--------------------------------Capsule filling (patent)

--------------------------------Free station

--------------------------------Rejection device

--------------------------------Free station

--------------------------------Capsule locking

--------------------------------Finished output

--------------------------------Mold cleaning

*** The capsule filling mechanism-Patent

Adopting three-dimensional adjustment, high dosing accuracy, morestable operation.adding powder recovery device, the recovery rate is100%.Patent number: CN205215743U.

*** A new patent used in 1500D model, has recovery device.

The material collection system

The separation device has been innovated to separate the powder from the waste capsule and avoid the pollution of the reclaimed powder.

*** Seperate the powder of working to avoid the 1500 D pollution

*** Why choose us?

Our capsule filling machine the 1500 D is an improved D model. The volume is smaller than the same products, but the production of the speed is also the excellent. Different from the old type products, the D models have been the solved and upgraded in the working process of the turntable, filling and the waste removal. What we to pursue is the to create the greater benefits for customers, the design of the turntable is evenly stressed and the frictions is small; the filling position which needs to be the replaced frequently is modularized; the waste removal position with the improved accuracy is specially added.

After the our long-term market investigation and the field research, in the process of the filling capsules, there will be some errors such as the incorrect separation of capsules, the capsule rupture, lack of materials, material the overflow and so on. In order to improve the working accuracy of the capsules filling machines, we installed the vacuum suction device after the filling material working position, which is the functions of the weeding waste.

IPv6 network supported

IPv6 network supported