DPP-270S Liquid Blister Packing Machine

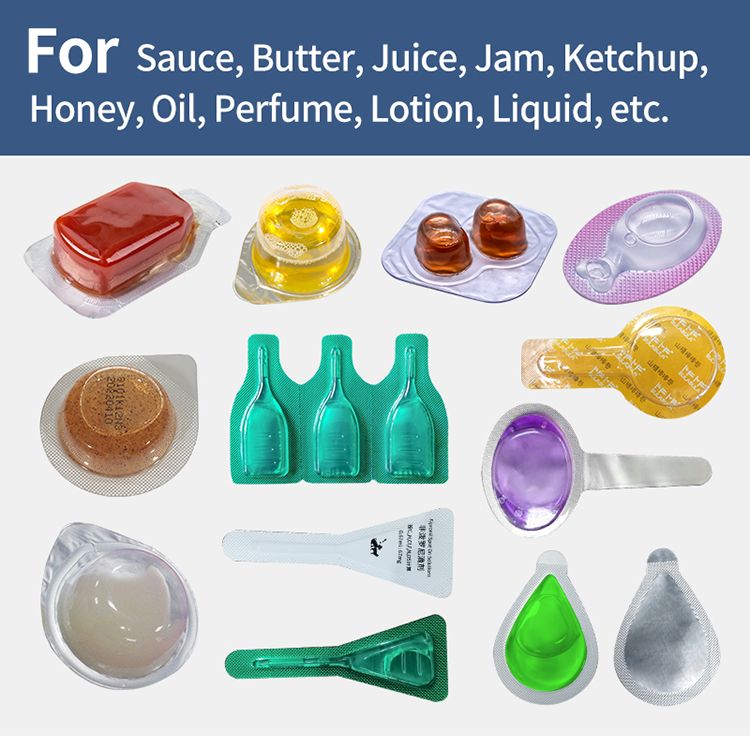

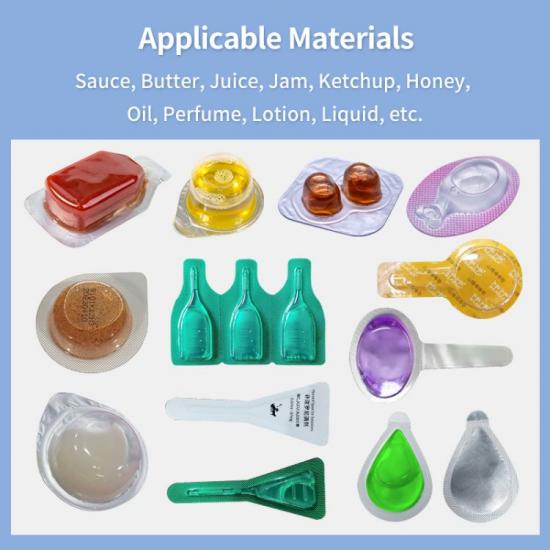

DPP-270S liquid blister machine is the latest high-speed flat blister packaging machine developed by Guangdong Rich Packing, specially designed for packaging liquid materials, such as ketchup, jam, honey, butter, perfume, etc. DPP270S is driven by Siemens servo motor, with higher packaging accuracy and more stable operation. With balcony platform structure, you can reach all corners of the machine without leaning over, which makes cleaning and maintenance more convenient. Mold adjustment is more convenient and quicker.

According to the different material properties, we have designed a variety of feeders for DPP270S. Ordinary materials use peristaltic pumps, which are cost-effective and have a feeding accuracy of more than 97%. Materials with higher viscosity can use plunger pumps. If the loading volume is relatively small and the loading accuracy is high, we can also use ceramic pumps for feeding. By configuring servo motors, the feeding accuracy of the blister machine can be improved. Each feeder is equipped with an independent servo, or a servo motor controls multiple feeders.

The four stations of forming, heat sealing, creasing and punching of the DPP270S liquid blister packaging machine are all positioned by mandrels, which can be freely adjusted through external hand wheels. Each station is equipped with a digital display, and the adjustment range is clear and clear, which greatly facilitates the adjustment and alignment of each station.

The forming, heat sealing, creasing and punching molds of the DPP270S liquid blister packaging machine are all designed with integrated modules, and are installed with quick-connect drawer-type pull-outs. It is very convenient and quick to replace the molds. After training, the operator can complete the replacement of the full set of molds in 10 minutes.

The modules connecting compressed air and cooling water at the blister forming station are independently placed downward, which solves the problems of difficult maintenance and easy wear of machine parts.

The heat sealing station adopts a double-cylinder four-column double-axis linkage, the heat sealing plate surface is horizontal and the pressure is balanced, so that the packaging materials on both sides have good adhesion, the finished product has clear texture, and the back of the blister is wrinkle-free.

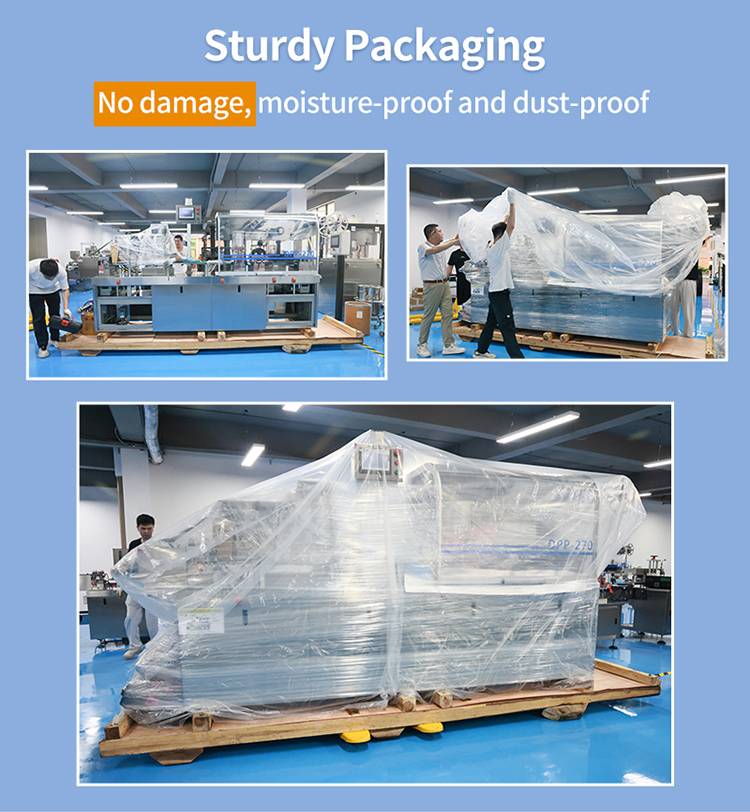

The DPP270S liquid blister packaging machine has fully automatic forming, feeding, sealing, batch printing, cutting and other functions, which meets GMP production requirements. It is popular in North America, Europe and Southeast Asia. It is an ideal product for medium and large-scale production in pharmaceuticals, health products, chemicals, food, etc.

*** Technical parameter

|

Model |

DPP-270S |

|

Production Capacity |

11,200 plates/hj |

|

Max. Shaping Dia. And Depth |

250*140*15mmMax. Depth26mm(custom-made) |

|

Power supply |

380V/220V/50Hz |

|

Standard Travel Range |

40~185mm |

|

Standard Plate |

80*57mm |

IPv6 network supported

IPv6 network supported