A high-speed rotary tablet press is a specialized machine used in the pharmaceutical industry to produce tablets at extremely high output and excellent consistency. The standard for evaluating whether it is a high-speed tablet press is whether the rotating plate speed exceeds 50 revolutions per minute. In this article, we will explore the key aspects of a high-speed rotary tablet press, including its design, working principle and application.

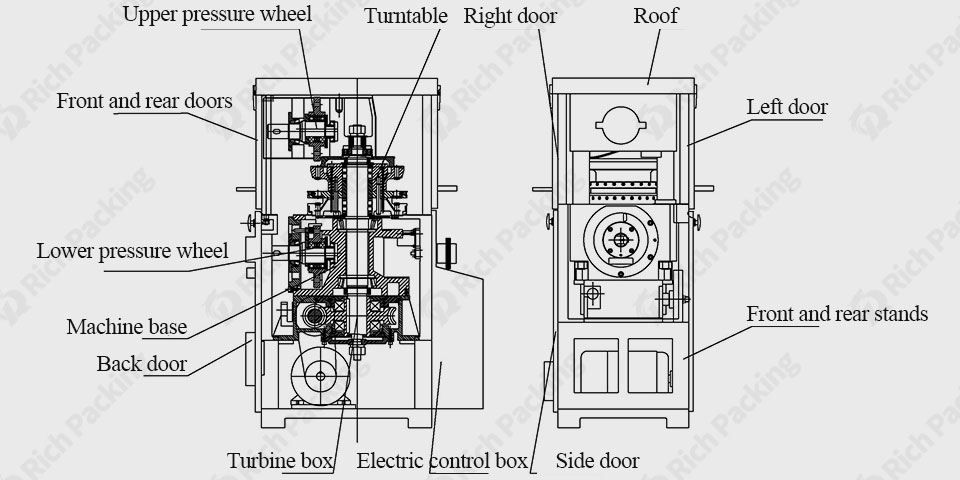

A high-speed rotary tablet press is a complex design designed to produce tablets at extremely high output while maintaining excellent stability. The main structure of the high speed rotary tablet press consists of several key components, includes the machine base plate, front and rear uprights, front and rear frames, worm gear box, machine base, punch plate assembly, the upper support block and the control cabinet. Now, let us take a closer look at these parts of high speed rotary tablet press one by one:

The bottom plate in rotary tablet press serves as the foundation of the machine and provides stability and support for all other components. It is usually made of a strong material such as steel to ensure that the machine remains level during operation, which is critical for accurate tablet forming.

The front and rear uprights are structural supports that hold the entire rotary tablet press machine in place. Both of them are usually made of high strength and high hard iron steel, and they are designed to withstand the forces generated during the tablet pressing production. The stand also serves as a mounting point for the punch and platen assembly and other drive systems.

The front and rear frames help stabilize the rotary tablet press machine and provide additional support for the moving parts. These frames are usually made of reinforced structures to ensure that the tablet press runs smoothly and efficiently. They may also contain some of the internal components of the machine, such as the punch rods.

The turbine box is a key component that converts the high-speed rotation of the motor into the low-speed, high-torque motion required for the tableting process. It usually contains gears and bearings that slow the running speed of the main motor output shaft while increasing the torque. The turbine box is responsible for driving the turntable, which is the core rotating component of the rotary tablet press.

The machine base is the main support structure that holds the entire rotary tablet press machine. It is usually made of strong and hard materials and designed to evenly distribute weight to the ground. The machine base also houses many of the internal components of the machine and is easy to maintain and repair.

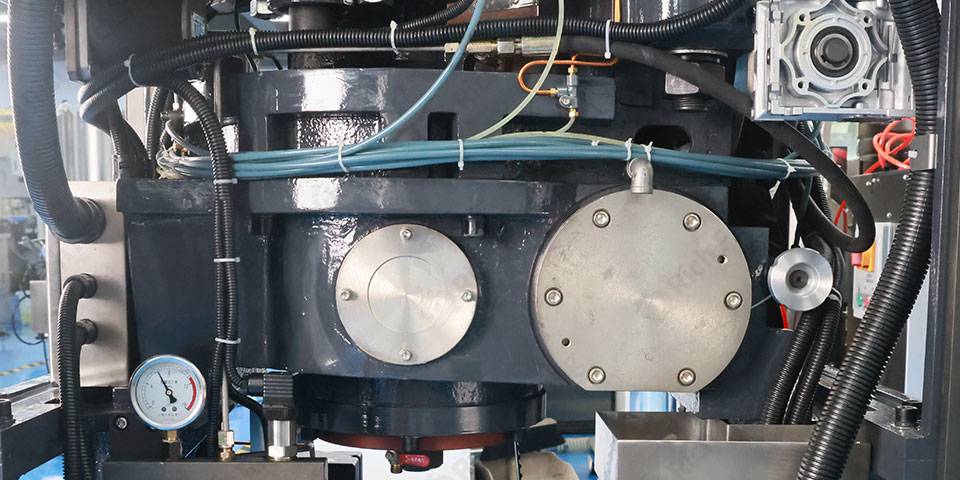

The Turntable combination includes upper and lower punches, which are the tools that compress the powder into tablets. The punches are usually made of high quality GCR15 steel and are designed to withstand the high pressures involved in the tableting process. They are mounted on the turntable and move in and out of the die cavity as the turntable rotates.

The upper support block is a structural element that strengthens the frame of the rotary tablet press machine and provides support for the upper components. It helps to maintain the alignment of the tablet press machine's punch assembly and the other moving parts. The upper support block may also contain mechanisms for adjusting the punch position and ensuring correct tablet formation.

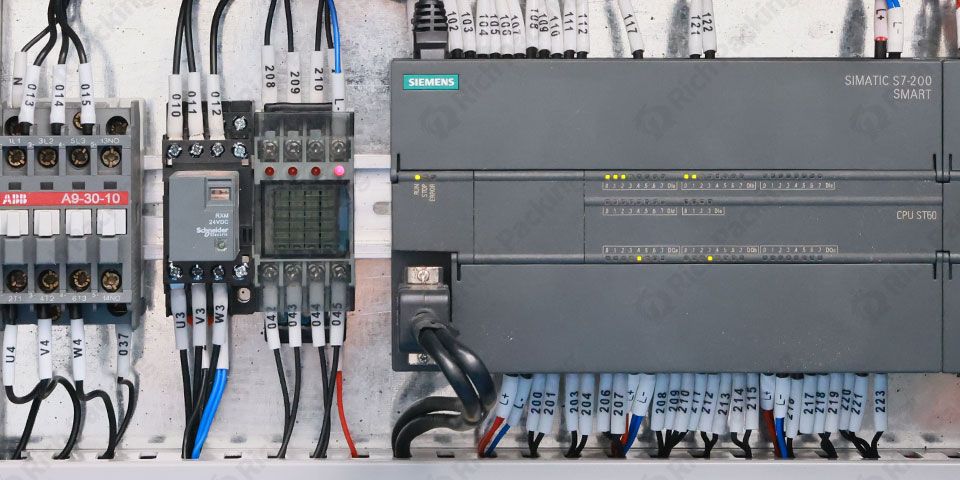

The control cabinet contains a electrical and electronic components that control the operation of the high speed rotary tablet press. It usually includes a programmable logic controller (PLC), a touch screen interface, sensors, and other monitoring and control devices. The control cabinet enables the operator to set and adjust various parameters such as tablet weight, compression force, and production speed.

The base plate, the front and rear uprights, front and rear frames and worm gear box are bolted together to form a fixed frame, which forms the foundation of the tablet press. The turbine box is fixed to the tablet pressing machine base. Based on the turbine box, the functional components of the tablet press, such as the tablet discharge guide, filling guide, lower punch protection guide, filling and metering mechanism, lower punch protection device, lower pre-pressing wheel, main pressing wheel adjustment mechanism and die removal block, are mounted on the machine base.

The support block connects the punching plate and the upper guide plate to the high speed rotary tablet press machine base through the left and right column tie rods and the tie rod passing through the center of the main shaft, forming the stable three-column frame structure. This structure has a extremely strong anti-bending and a anti-torsion capabilities to meet the load-bearing requirements of the high-speed tablet press even when it is running at high speed. The support block is equipped with a guide plate, an upper pre-pressing wheel, an upper main pressing wheel, an upper punch over-tightening protection device, etc. A vibration reduction system is installed between the upper top plate and the support block. Four plexiglass doors are installed on the four sides of the rotary tablet press's upper top plate, and each plexiglass door is equipped with a telescopic spring to provide supporting tension for each plexiglass door.

The upper part of high speed rotary tablet press is a completely sealed tablet press chamber, which is the part that completes the entire tablet press process. It includes a forced feeding system, a punching assembly, a tablet discharge device, and a dust collection system. The tablet press chamber is completely sealed by a top plate, a cover plate, and a plexiglass door through a sealing strip to prevent external pollution of the tablet press process.

The lower part of the high speed rotary tablet press nachine is equipped with the main transmission system, the lubrication system, and the handwheel adjustment mechanism. The left and the right door panels, the rear door panel, and the control cabinet seal the lower part of the rotary tablet press machine through sealing strips to prevent dust from entering the machine completely.

Understanding the functions of each component of a high-speed rotary tablet press is essential for effective operation and maintenance. Each component in the high speed rotary tablet press machine plays an important role in the overall function and the performance of the machine. By properly maintaining these components, manufacturers can ensure the consistency of tablet quality and maximize production efficiency.

Rich Packing has over 31 years of experience in manufacturing high quality tablet presses. If you would like to know more about tablet presses, please contact us.