Have you ever wondered how those tiny capsules containing your daily supplements or medications are filled with such precision? The world of capsule filling is a fascinating blend of science, technology, and ingenuity. From manual methods used in small-scale operations to high-tech automated systems in pharmaceutical giants, the process of filling capsules is more complex and varied than you might imagine. Join us as we explore the diverse methods of capsule filling, and discover which approach might be right for your needs.

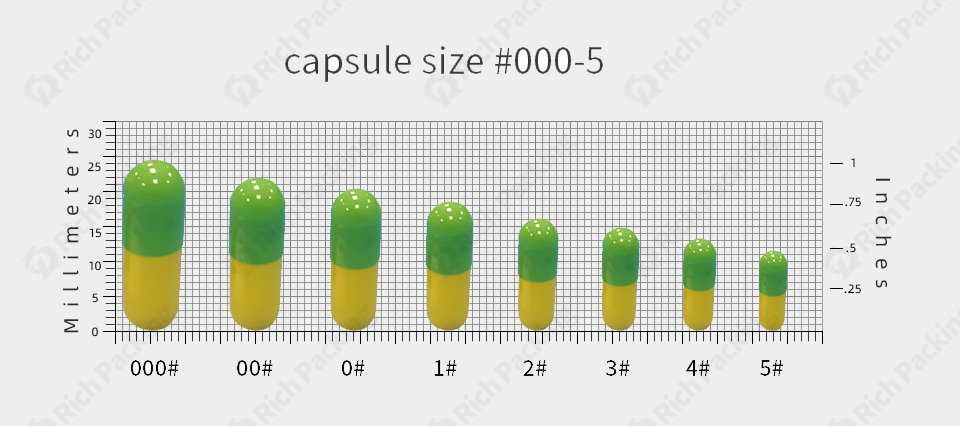

Before diving into the various filling methods, it's essential to understand the basics of capsules themselves. Capsules are typically made from gelatin or cellulose and come in two parts: the body (longer part) and the cap (shorter part). They're available in different sizes, usually numbered from 000 (the largest) to 5 (the smallest), with size 0 and 00 being the most common for dietary supplements.

Capsule sizes are crucial in determining the appropriate filling method and machinery. Here's a quick overview of common capsule sizes and their typical uses:

- Size 000: Largest size, used for bulky powders or multiple pills

- Size 00: Common for supplements and larger dosage medications

- Size 0: Widely used for supplements and medications

- Size 1 and 2: Often used for antibiotics and smaller dose supplements

- Size 3 and 4: Typically used for oils and lower-dose medications

- Size 5: Smallest standard size, used for very low-dose drugs or children's medications

Now that you're familiar with capsule basics, let's explore the various filling methods available.

Manual capsule filling is the most basic method and is often used for small-scale production or when creating custom formulations. Here's how it works:

1. Separate the capsules into body and cap sections.

2. Place the capsule bodies into a holding tray with holes sized to fit the capsules.

3. Fill each capsule body with the powder or content using a small scoop or spatula.

4. Tamp down the powder to ensure consistent filling.

5. Place the caps back onto the filled bodies and press to seal.

While time-consuming, this method allows for precise control over the filling process and is ideal for small batches or when dealing with expensive ingredients. It's commonly used by compounding pharmacies, herbalists, and small supplement manufacturers.

- Low initial investment

- Suitable for small batches

- Allows for custom formulations

- Time-consuming

- Labor-intensive

- Potential for human error

Semi-automatic capsule filling machine, capsule separation, powder filling and capsule closing operations to achieve mechanical automatic completion, only manual operation in each process step, greatly improve the output and save labor costs. Here's how they typically work:

1. Load empty capsules into the machine's tray.

2. The machine separates the capsule bodies and caps.

3. Fill the powder hopper with your product.

4. The machine dispenses the powder to each capsule in a set amount.

5. Optionally, you can add a tamping step to compress the powder.

6. The machine reattaches the caps to the filled bodies.

7. Finished capsules are ejected from the machine.

Semi-automatic machines come in various sizes, capable of filling anywhere from 100 to 5000 capsules per cycle. They're an excellent choice for medium-scale production or businesses looking to scale up from manual filling.

Here we use the CGN-208 semi automatic capsule filling machine of rich packing as an example. The output of this equipment can reach 28,000 PCS /h, which is more than 90 times higher than the output of 100-300pcs/h by manual filling. Save a lot of labor and time costs, greatly improve the production efficiency.

Pros:

- Increased production speed compared to manual filling

- More consistent fill weights

- Suitable for medium-scale production

- Higher initial investment than manual methods

- May require some training to operate effectively

- Less flexible than manual filling for custom formulations

Automatic capsule machine output of up to 468000pcs/h, suitable for mass production, with vacuum powder feeder and hollow capsule feeder can achieve no manual intervention production.Here's a simplified overview of the process:

1. Empty capsules are loaded into a hopper.

2. The machine orients and separates the capsules.

3. Capsule bodies are positioned in the filling area.

4. The powder or content is precisely dosed into each capsule body.

5. Capsules are optionally tamped to ensure consistent density.

6. Synchronize the capsule cap to the filled valve body.

7. Complete the lock combination of capsule cover and shell to automatically pop out and collect.

8. Quality control, quality prosecution of weight, appearance and metal detection.

Fully automated machines can handle a wide range of capsule sizes and filling materials, including powders, particles, liquids, and even combinations of these. The filling mechanism can be added and the PLC program can be upgraded through the refilling rotary table to achieve the effect of multiple material combinations, which is suitable for the use of special formulas. The world's cutting-edge fully automated capsule fillers also include advanced features such as weight checks, metal detection and automatic removal of defective capsules, and real-time connectivity of production data to service terminals.

Such as Rich Packing NJP-3800D Automatic Capsule Filling Machine, can fill different types of capsules such as #000-#5, can fill powder, particles, liquid or combined material filling and automatic waste removal function, the output can reach 228000psc/h. It is an ideal choice for mass production of drug capsules in pharmaceutical and health product companies.

Pros:

- High production speed (up to 228,000 capsules per hour)

- Consistent fill weights and quality

- Reduced labor costs

- Suitable for large-scale production

- High initial investment

- Requires skilled operators and maintenance staff

- Less flexible for small batches or frequent formulation changes

While powder filling is the most common method, liquid filling is also widely used, especially in the pharmaceutical industry. There are several approaches to liquid capsule filling:

1. Thermo Sealing: Liquid is filled into the capsule body, and the cap is sealed using heat.

2. Banding: After filling, a gelatin band is applied around the joint of the capsule to prevent leakage.

3. Liquid Encapsulation: The entire capsule is formed around the liquid content in one step.

Liquid filling machines can be semi-automatic or fully automatic, depending on the production scale. They require careful temperature control and precise dosing to ensure consistent fill volumes and prevent leakage.

Pellet Filling Methods

Pellet filling is another specialized method, often used for controlled-release formulations. Pellets can be filled using two main approaches:

1. Gravimetric Filling: Pellets are dosed by weight into each capsule.

2. Volumetric Filling: A specific volume of pellets is dispensed into each capsule.

Pellet filling machines often incorporate features to prevent pellet breakage and ensure even distribution within the capsule.

Selecting the appropriate capsule filling method depends on several factors:

1. Production Volume: Manual for small batches, semi-automatic for medium scale, and fully automatic for large-scale production.

2. Product Characteristics: Powder, liquid, or pellet formulations require different filling approaches.

3. Capsule Size and Type: Ensure your chosen method can handle your specific capsule requirements.

4. Budget: Consider both initial investment and long-term operational costs.

5. Flexibility: If you frequently change formulations, a more flexible method might be preferable.

6. Quality Control Requirements: Automated systems often offer more consistent results and built-in quality checks.

7. Regulatory Compliance: Ensure the chosen method meets relevant industry standards and regulations.

As technology advances, new innovations are shaping the future of capsule filling:

1. 3D Printed Capsules: Custom-shaped capsules for unique formulations or branding.

2. Smart Capsules: Incorporating sensors for targeted drug delivery or monitoring.

3. Robotic Systems: Increasing automation and flexibility in capsule filling processes.

4. AI and Machine Learning: Optimizing fill weights and detecting potential issues in real-time.

5. Continuous Manufacturing: Moving away from batch production for increased efficiency.

As you've discovered, capsule filling is a diverse and evolving field, offering solutions for everything from small-scale custom formulations to massive pharmaceutical production runs. By understanding the various methods available, you're better equipped to choose the right approach for your needs. Whether you're a small supplement producer or a large pharmaceutical company, the world of capsule filling continues to innovate, promising even more efficient and precise solutions in the future.