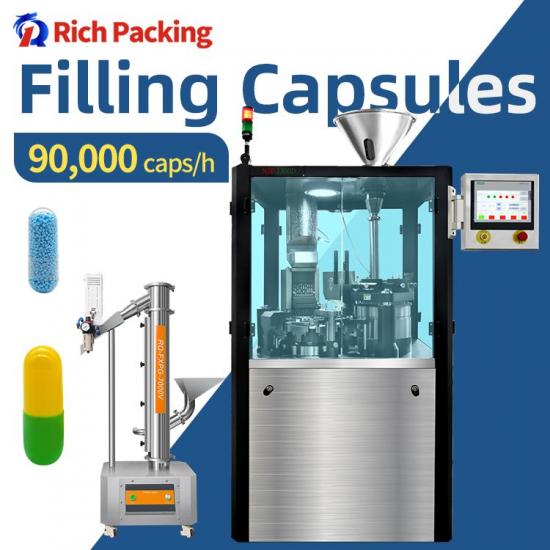

000 Capsule Filling Machine USA

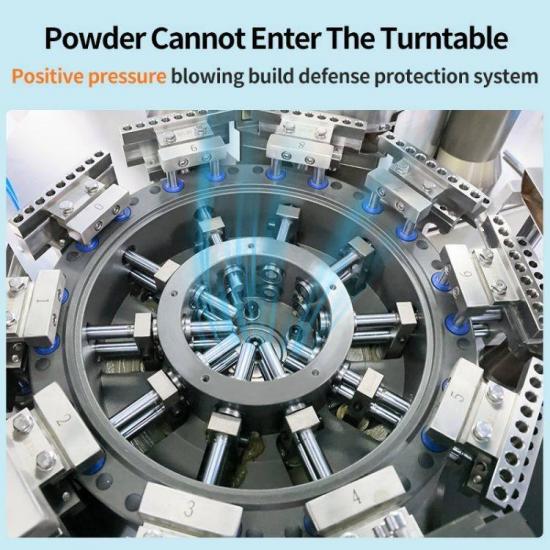

This automatic capsule filling machine filler not just suitable for the traditional medicine filling but also suitable for filling the western medicine. And capsule making machine this type has the advantages as the high loading accuracy and very stable operation and no dust. This Capsule Filling Machine no dust has success rate of 99.99% in capsule separating, and it has final product qualified rate of 99.8% and it meets the standards of GMP cGMP. The whole working of filling from the beginning of sowing to the end of the final putout of capsule is extremely low in failure rate.

This is the easy operating powder particle capsule filling machine which is perfect in smooth running of low smooth material filling.

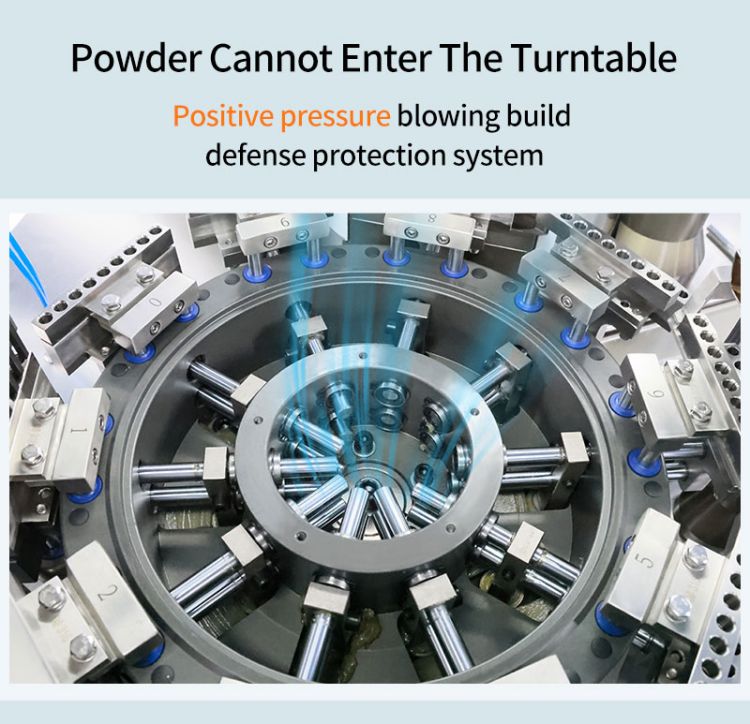

This machine can deal with the material that is not so easy to run and this special and has wonderful advantages for it has adoption of the novel Pneumatic discharge.

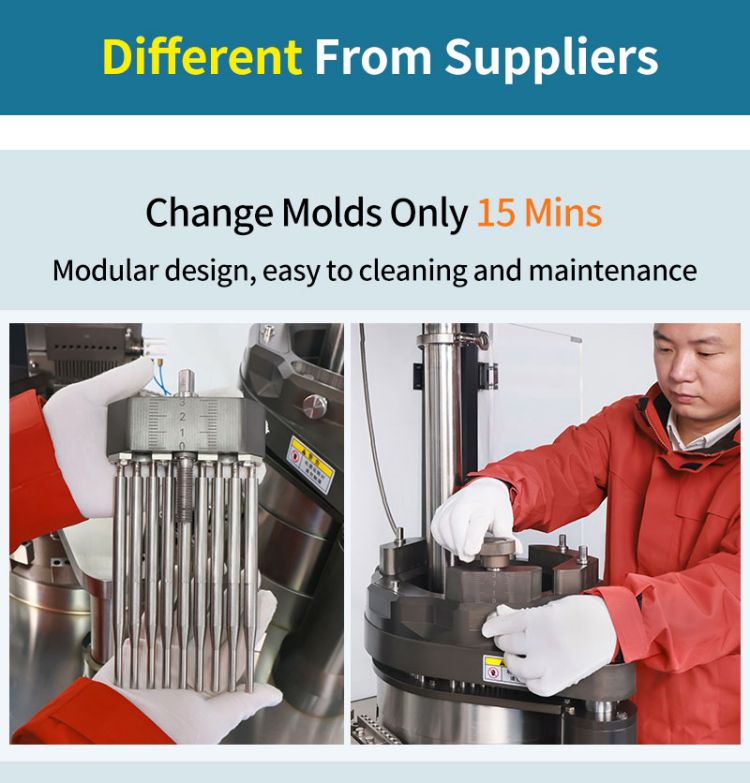

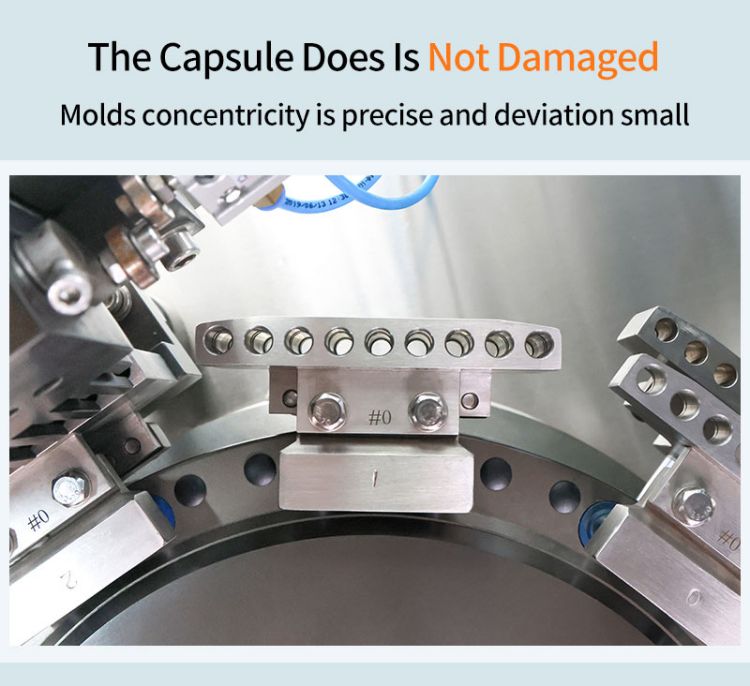

This 1500D machine is very easy to operate and the reason is 1500D has better scientific design in both the body structure as well as the molds.

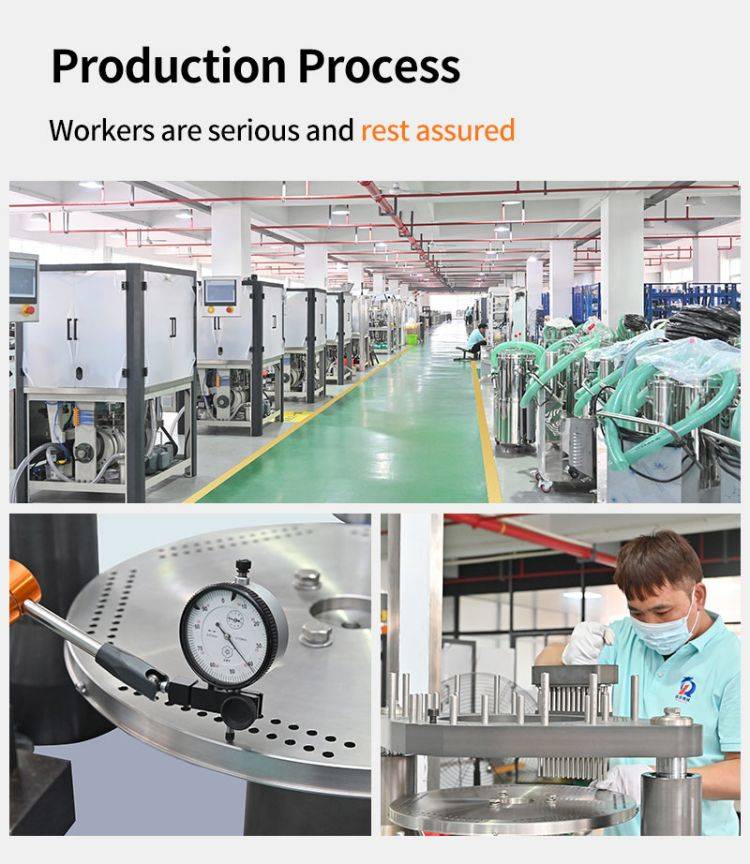

Why choose us?

This is a good-performance pharmaceutical capsule filling filler machine which is easy to maintain . And these capsules machine are very easy to add lubricating oil. 1500D will never have the situation of the oil leaking.

And it running smoothly all the time in the filling running and the adding oil progress can ensure the smooth running of the drive mechanism.

This filling capsule machine has high degree of safety and it has low error rate in less than 3% or even less than that.

*** Technical parameter

|

Production capacity |

90000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size of machine |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

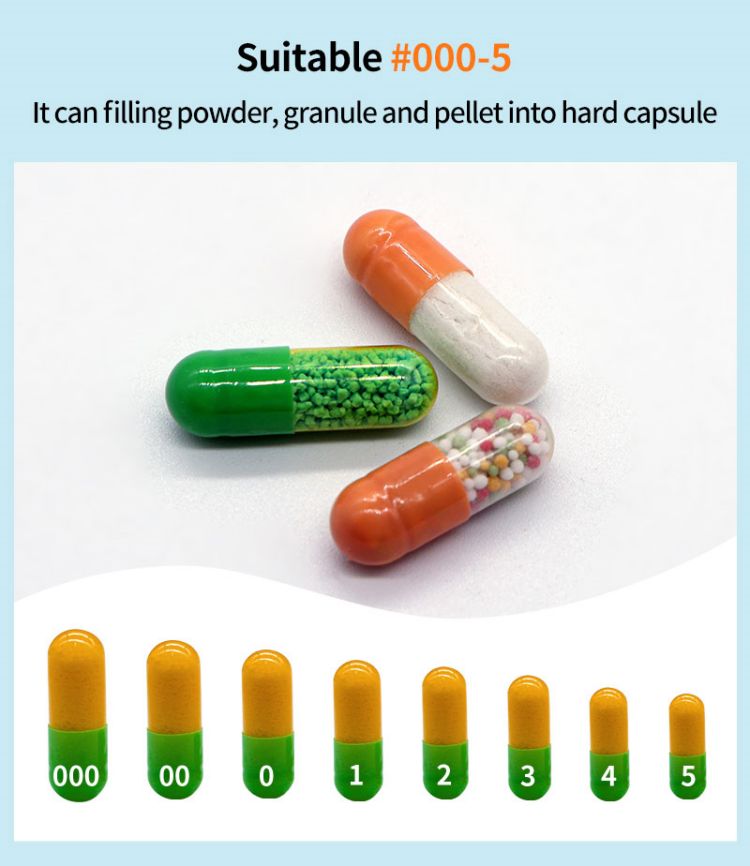

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

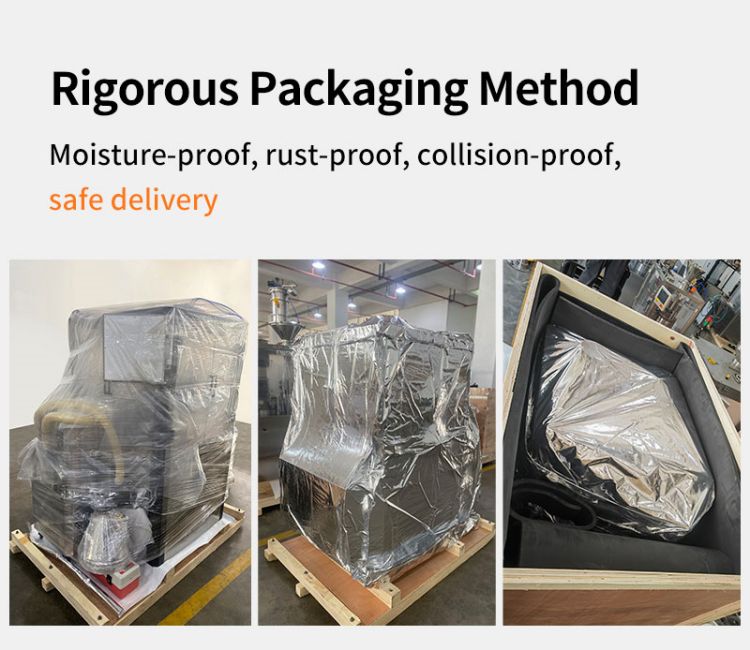

Packing size |

1490×1260×2150mm |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

VFD015 B21A |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

CH-30-1100W |

1 |

Dongli |

|

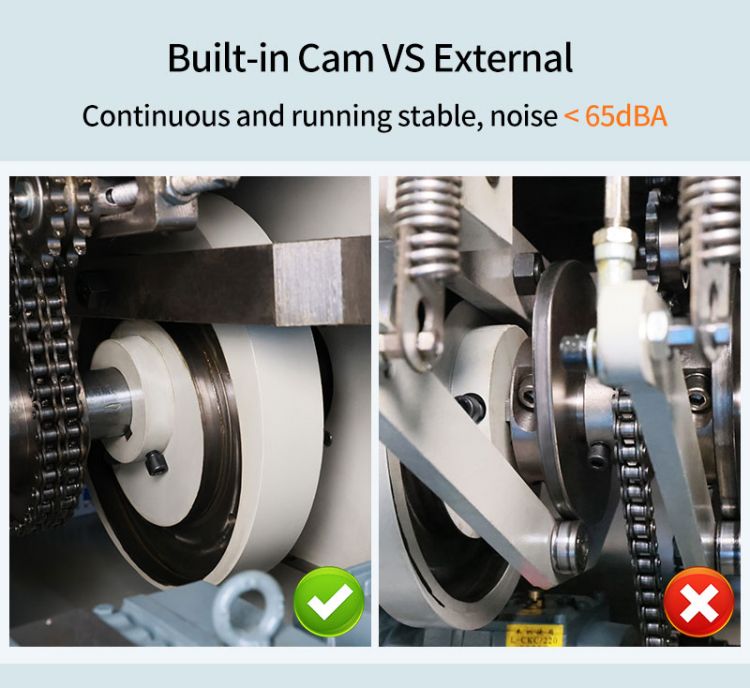

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwandaojin |

|

Vacuum pump(wet) |

SK-0.5A |

1 |

Shanghai |

|

Dust collector |

XLJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

IPv6 network supported

IPv6 network supported