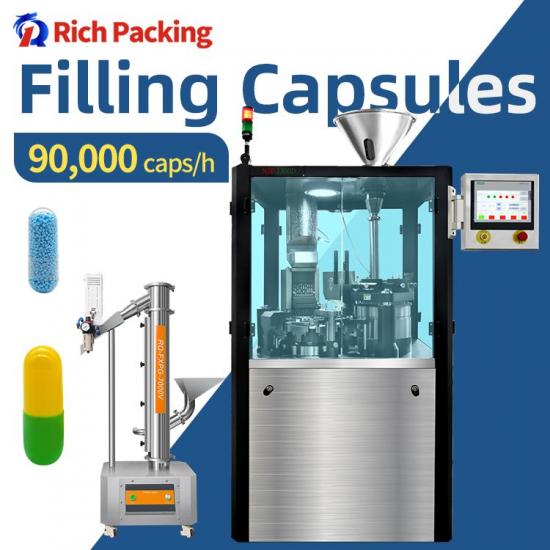

Capsule Filler Capsule Filling Machine Automatic NJP of Rich Packing

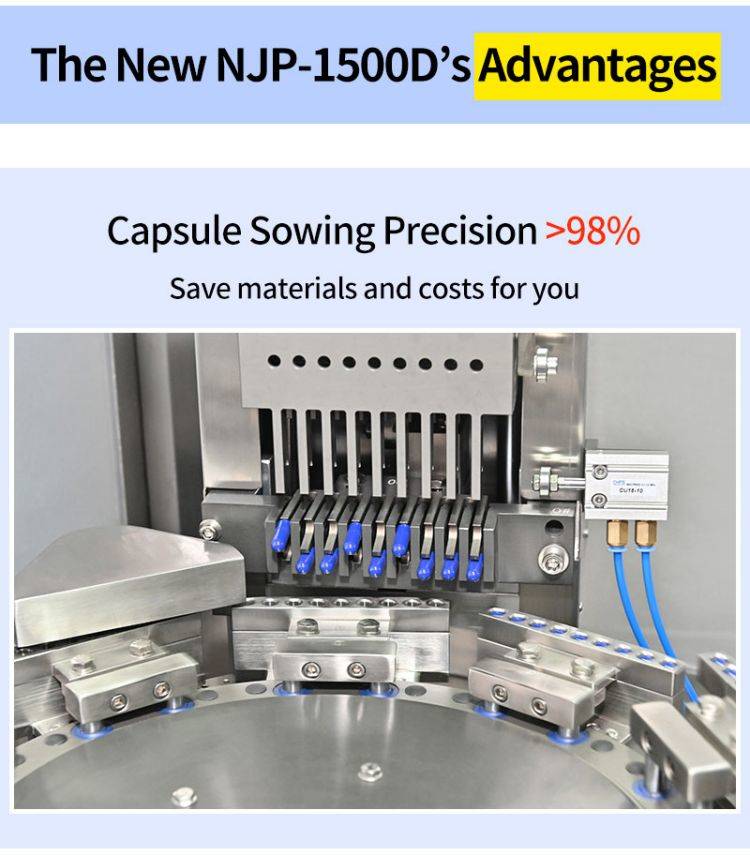

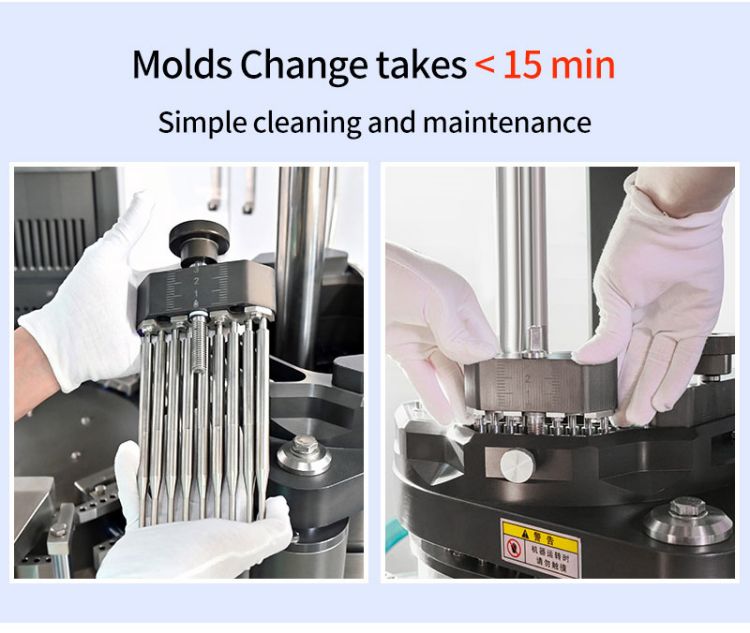

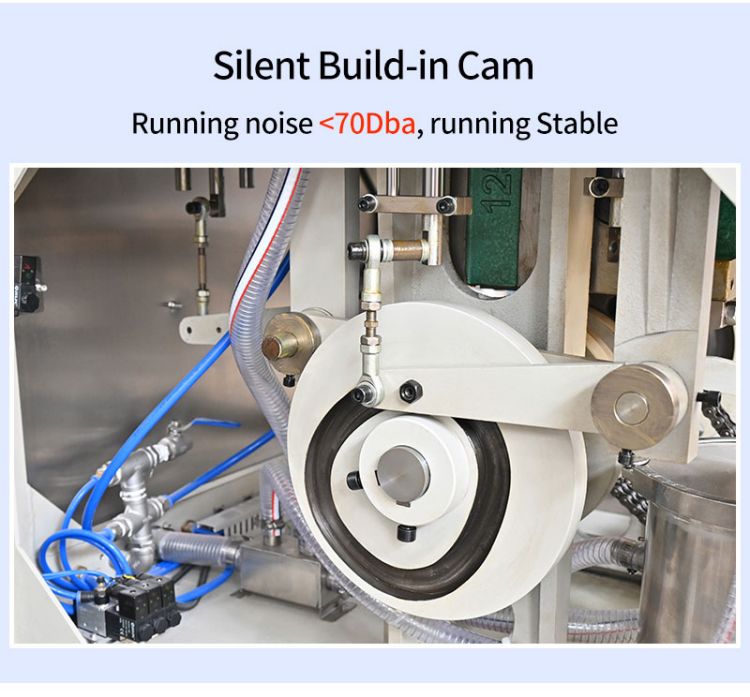

Capsule filling machine 1500D is easy for cleaning, zero dirty is one of 1500D’s strengths, it is very environmentally friendly and very economical. This machine can work very efficiently from the day morning to night under the condition of continuous running, and it can run with low less than 75dba noise. Moreover, many kinds of filling rods are easy to change and have zero deviation to make sure the quality of the capsules without any scratches or damage.

The adjustment process and the method of the gap between the capsule dosing disc and the sealing rubber ring of the automatic hard capsule filling machine. The gaps between the dosing disk and the capsule sealing ring of the automatic capsule filling machine is about 0.03 to 0.08mm. When the powder pellets are large, the interval would be adjusted to be larger. If the gaps are too small, the resistance between the dosing disk and the sealing rings will increase. During the filling operation of the fully automatic capsule filling machine, it is necessary to adjust the gaps when too many powder leakage or the excessive resistance is found.

This automatic capsule machine adjustment method: to loosen and remove the five screws on the baffle, loos the set screw and the set nut, then turn the five adjusting bolts evenly and carefully in turn for adjusting the height of the rubber rings, check it with a feeler gauge For the gaps, check about three to five measuring points, so the gaps at each point should be consistent, and make sure that the five adjusting sleeves are in contact with the sealing rubber rings. After the checking inspection is completed, the first tighten the set screw, and then tighten the set nut.

*** Technical parameter

|

Production capacity |

90000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size of machine |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

VFD015 B21A |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

CH-30-1100W |

1 |

Dongli |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwandaojin |

|

Vacuum pump(wet) |

SK-0.5A |

1 |

Shanghai |

|

Dust collector |

XLJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

IPv6 network supported

IPv6 network supported