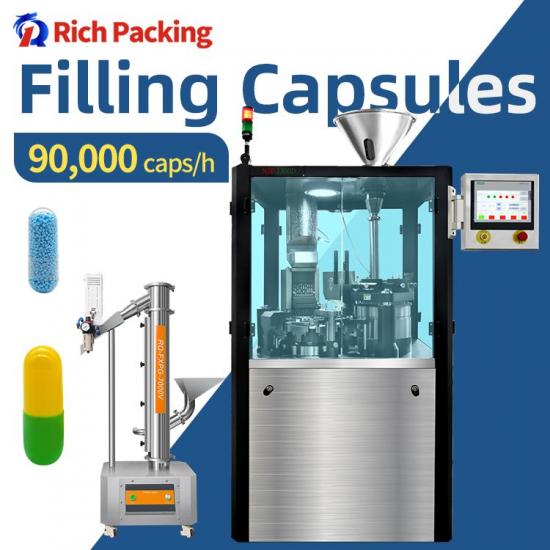

NJP-1500 Medicinal Capsule Filling Machine

In the old type medicine filling capsule machine, after the turntable runs for a very long time, powder particles will remain on the dosing plate and these bearing, affecting the stability of operating. At the end in contrast, our Rich Packing combines the new clean technology with the turntable.

Between the filling capsules process, the last working position is equipped with a large vacuum device system. After the machine finishes a circle of production fill process, it must pass through the cleaning working station point. The cleaning point absorbs the residual powder granules and capsule’s shell through the ultra high pressure exhaust device to ensure the smooth and the stable next operation.

Since the industrial upgrading brought about by the invention of the steam engine in Europe, about 150 years ago, many Western European facilities powers took the lead in replacing the pure manual production of multi functional individuals with machine production in the field of industrial production. So far, due to the changes of transportation mode, the human resources and technology exchanges between countries and the regions on the Earth are increasing. And some kinds of backward countries, such as capsule filling machines, can also gain their goals through continuous learning, so narrowing the gap in regional development.

Our mechanical capsule filling machine well welcomed by many countries and regions is sold to Bahrain, Jordan, Kuwait, Iran, Iraq, Egypt, Israel, Lebanon, Saudi Arabia, Syria, Oman, Qatar, Palestine, UAE and many other countries and regions.

*** Technical parameter

|

Production capacity |

90,000 pcs/h |

|

Overall size |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

IPv6 network supported

IPv6 network supported