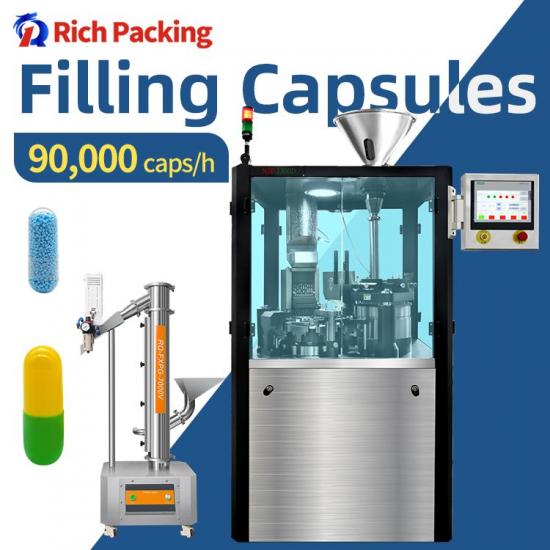

NJP-1500 Pharma Automatic Making Capsule Filling Machine

The automatic way of distinguishing the filling capsule automatic machine is that if the manual participation of users is required during the manual addition of the raw materials, such as the various sizes of hard hollow capsules shell and the herbal medicine edible powder, until the final finished capsule is made.

If there is necessary for users to pick up the capsule tray and fill it at the next working station during production, then this machine belongs to the semi-automatic filling capsule automatic machine.

That is a fully automated filling capsule automatic machine if it is operated by a machine program all the time and no human intervention was required.

There is no absolute advantages or disadvantages between these two machinery with different degrees of automatic. Semi-automatic type produce less, but do not waste materials. The output of automatic model is very large, but for the using of materials, relatively some waste.

Our company now develops and operates markets covering all major regions of the whole world, in which North America and Europe and other prosperous countries accounted for more than 50% of the market turnover. Customers in west Asia also like the equipment produced by RQ group workshops, accounting for 30%. South Africa and other less prosperous areas, the market accounted for more than 10%, but because of the numerous, broad area, the number of countries, the prospects of the market is very widely.

*** Technical parameter

|

Production capacity |

90,000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

IPv6 network supported

IPv6 network supported