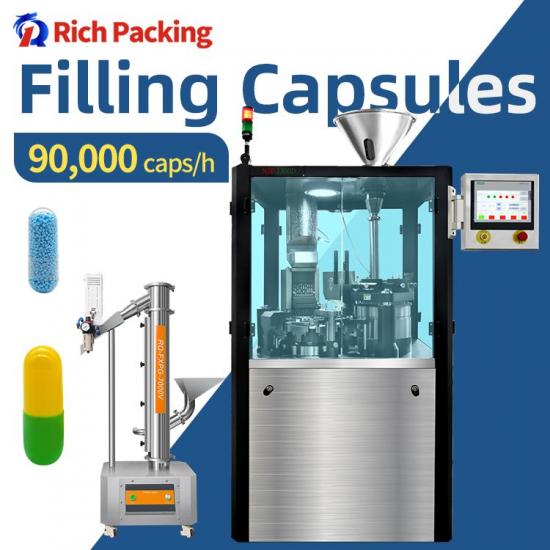

NJP 1500D Automatic Capsule Filling Machine By Rich Packing

The primary working progress of the fully automatic capsule filling machine is that when the capsule machine running, the capsules from the capsule hopper will vertically enter in the first delivery fork of the dispensing equipment one by one.The downward movement of the leading pick will send six capsules at one time, and the rubber cap is on the top. In the first running task, the vacuum separating system will slide the capsules into the module and at the same time move the capsule body cap away.

When the turntable is intermittently twisted to the second workstation, the upper dies meter quickly rises and moves inwards. In the fifth workstation, the capsule filling rod pushes the compacted grain into the capsules of the lower dies.The capsule that has not left is on the eighth workstation. The upper and lower modules are combined together on the tenth workstation, and the lower capsules’ body is pushed upward to make it buckle.

*** Why choose us?

In the eleventh workstation, the buckled capsule product is pushed out and is collected. In the twelfth workstation, the vacuum cleaner enters the next cycle after the clearing the module.

This kind of full automatic capsule filling machine will not make the noise during the high speed operation of capsule filling, and can change the molds conveniently and quickly for up to 15 minutes.

The auto intelligent machines 1500D can ensure 100% of the zero capsule damage and 100% of the capsule quality, all of which benefit from its 100% crystallize dilution accuracy.

*** Technical parameter

| Name |

fully automatic capsule filling machine |

|

Production capacity |

90000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size of machine |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

VFD015 B21A |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

CH-30-1100W |

1 |

Dongli |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwandaojin |

|

Vacuum pump(wet) |

SK-0.5A |

1 |

Shanghai |

|

Dust collector |

XLJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

IPv6 network supported

IPv6 network supported