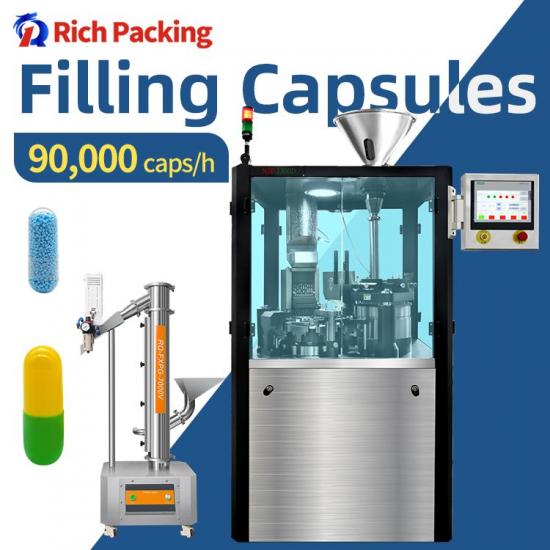

NJP1200 Capsule Filling Machine Full Automatic

The machine's cutting-edge technology includes intelligent control systems and precision-driven mechanisms that ensure seamless and precise encapsulation. Its ability to handle a wide range of capsule sizes, coupled with its adaptability to various formulations, makes it an indispensable asset in pharmaceutical production.

The NJP1200's advanced features extend beyond mere automation. Its intuitive user interface simplifies operation, allowing operators to navigate the machine's controls effortlessly. This simplicity minimizes the learning curve, enabling swift integration into production lines and reducing operational complexities.

Furthermore, the machine's robust design and adherence to stringent quality standards guarantee reliability and durability. This reliability translates into consistent, high-quality capsule production, meeting the rigorous demands of the pharmaceutical industry.

In addition to its operational prowess, the NJP1200C prioritizes safety and compliance. It incorporates safety features and follows strict regulatory guidelines, ensuring the integrity of the manufacturing process and the quality of the end products.

The NJP1200 Capsule Filling Machine stands as an embodiment of innovation, efficiency, and precision. Renowned for its efficiency, precision, and technological advancement, this machine stands as a testament to innovation in the industry. Its full automation capabilities redefine the landscape of pharmaceutical manufacturing, driving higher production capacities and maintaining dosage accuracy. As pharmaceutical companies strive for excellence and seek cutting-edge solutions, the NJP1200 remains a beacon of technological advancement, ensuring the efficient and reliable production of high-quality capsules for diverse healthcare needs.

*** Technical parameter

|

Production capacity |

72000 pcs/h |

|

Net weight of machine |

1100Kg |

|

Overall size of machine |

1100×910×2100MM |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

ATV320U07N4C |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

MTD-37-Y0.75 |

1 |

Omate |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwan daojin |

|

Vacuum pump(wet) |

RX25-V-0.3 |

1 |

Taiwan Ruixu |

|

Dust collector |

RQJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

IPv6 network supported

IPv6 network supported