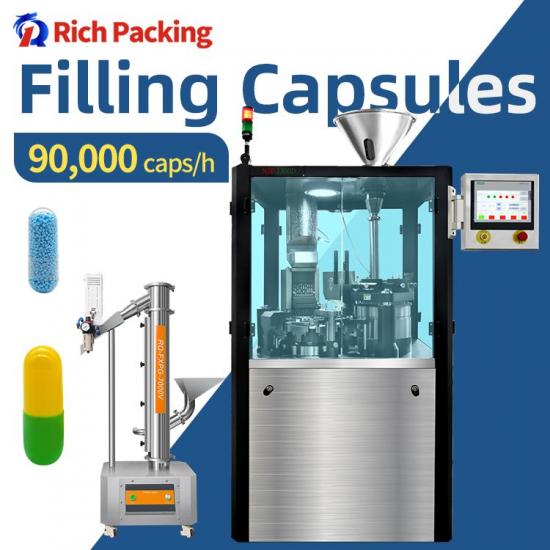

NJP1500 Capsule Filling Machinery

The working process of the capsule filling machine is as follows:

Capsule Separation: Capsules are separated and lined up with the help of vibrating discs.

Filling: The powder, granule or liquid is delivered to the filler through the powder supply system, and the filler will quantitatively fill the material into the capsule.

Compaction: After filling, the material in the upper portion of the capsule is exposed, at which point a compactor compresses the material and causes it to tightly fill the capsule.

Capsule discharge: After the capsule is filled, the capsule discharge system discharges the capsule for subsequent sealing work.

The principle of the capsule filling machine is to automate the capsule filling process by using technologies such as mechanical structure, electrical control, and sensor detection. Specifically, its principles mainly include the following aspects:

Capsule separation principle: through the vibration of the vibrating plate, the capsules are separated from each other under the action of centrifugal force.

Filling principle: Through the powder supply system, the material is sent into the filler, and the filler performs precise quantitative filling.

Compaction principle: Through the pressure of the compactor, the material is compacted in the capsule to fully fill the capsule.

Capsule-out principle: Through the mechanical structure, the filled capsules are sent into the capsule-out system, and the capsule-out operation is finally completed.

In addition, the capsule filling machine also needs precise mechanical processing and assembly, precise electrical control and debugging, and continuous optimization of process design to ensure its normal operation and high-efficiency work.

*** Technical parameter

|

Production capacity |

90,000 pcs/h |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

IPv6 network supported

IPv6 network supported