ZP-29D Single Sided Rotary Tablet Press Machine

Single-sided rotary tablet press play an important role in the pharmaceutical industry, especially machines like the Model 29D. This type of easy to operate automatic tablets machine press has attracted attention for its efficient production and diverse tablet pressing capabilities.

Highly efficient production capacity

The equipment for tablet press model 29D is known for its efficient production capacity. It can produce up to 110,000 tablets per hour, making it an ideal choice for pharmaceutical companies. This high-efficiency production capacity helps meet market demand and improve production efficiency.

Diverse tableting capabilities

The special feature of this pharmaceutical pill tablet press machine is its ability to press tablets of various sizes and shapes. Whether it is round, oval, square or other special shapes, they can be produced by the 29D model single-sided rotary tablet press. This flexibility allows pharmaceutical companies to adapt to different product needs.

Tablet process

The working principle of a single-sided pill machine automatic making tablet press involves a series of process steps. First, the medicinal powder or granules enter the mold cavity of the tablet press. Subsequently, the mold compresses the material into tablet shape by pressing and rotating. The characteristic of one-sided pressing means that each mold cavity only has one movement during pressing, which makes the operation of the tablet press simpler and more efficient.

Technical features

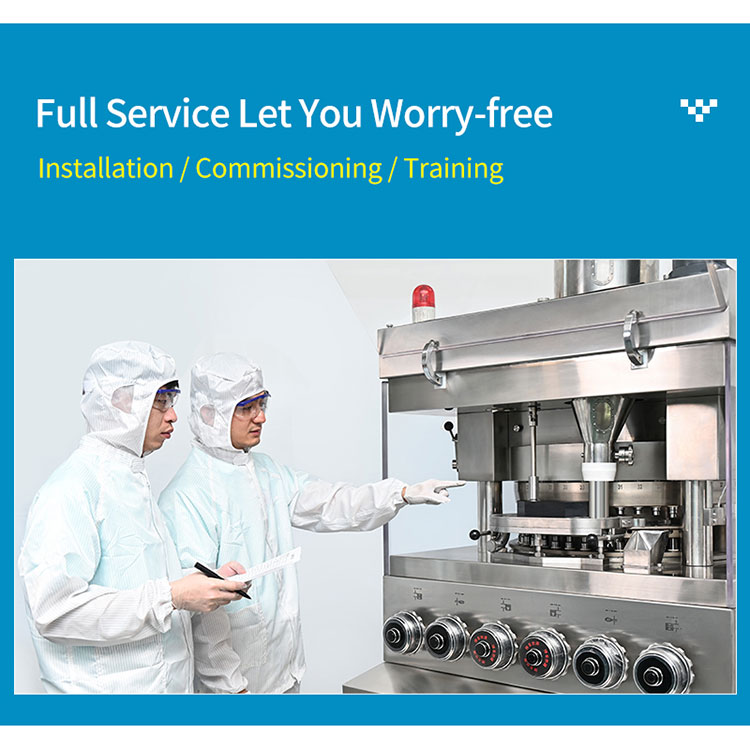

In addition to efficient production and diverse pill making tablet press machine capabilities, this model of single-sided rotary tablet press typically features advanced automated control systems to ensure consistency and quality of tableting. At the same time, they may also have compact designs and easy maintenance to meet pharmaceutical companies' requirements for production efficiency and equipment reliability.

*** Technical parameter

|

Dies No. |

29 set |

|

Max. Production Capacity |

110000 pcs/h |

|

Max. Pressure |

100KN |

|

Max. Dia. of Tablet |

24mm |

|

Max. Depth of Filling |

24mm |

|

Max. Thickness of Tablet |

12mm |

|

Length of Upper/Lower Punching Bar |

115mm/133.4mm |

|

Rotary Speed |

5~21 r/min |

|

Motor |

5.5kw |

IPv6 network supported

IPv6 network supported