ZP-29D Dietary Supplements Tablets Machine

State-of-the-Art Automation

Equipped with advanced tablet press effervescent tablet automation features, this machine optimizes the tablet production process. It efficiently compresses formulations into tablets of consistent weight, size, and hardness, meeting stringent quality standards.

High-Speed Production

Renowned for its high-speed capabilities, the automatic tablet press machine offers remarkable production rates, significantly increasing manufacturing efficiency. Its ability to produce a large quantity of tablets in a short time enhances productivity in pharmaceutical facilities.

Versatility and Precision

Adaptable to various formulations, the automatic medicine pill press machine accommodates different types of powders, granules, or mixtures to create tablets. Its precision in dosage ensures accurate medication delivery, crucial for pharmaceutical efficacy.

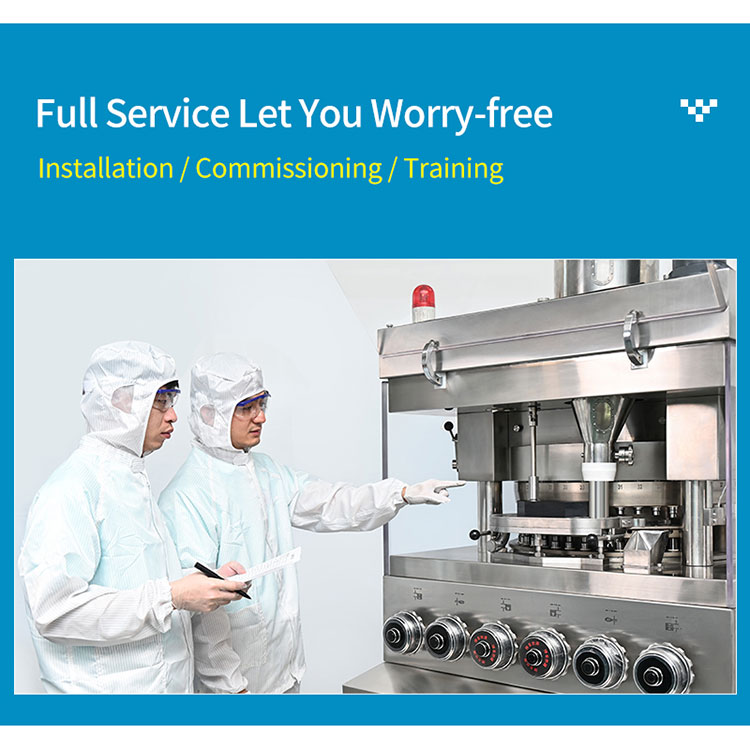

User-Friendly Interface

The machine's intuitive interface simplifies operation, allowing operators to monitor and adjust settings effortlessly. This user-friendly design reduces training time and enhances operational efficiency.

Quality Assurance

Committed to quality assurance, the automatic tablet press machine undergoes rigorous testing and adherence to industry regulations. It ensures consistent tablet production, meeting the highest standards for pharmaceutical and nutraceutical manufacturing.

Innovative Technology

Integrated with innovative technology, such as intelligent control systems and safety features, this machine ensures smooth operations while prioritizing user safety and product integrity.

Meeting Industry Demands

As pharmaceutical needs evolve, the automatic tablet press machine remains pivotal in meeting the increasing demand for high-quality tablets. Its reliability, precision, and efficiency contribute significantly to fulfilling the pharmaceutical industry's requirements.

The pill making machine press machine is a cornerstone of pharmaceutical manufacturing, revolutionizing the production of tablets with its efficiency, precision, and high-speed capabilities. Its role in streamlining tablet formation processes and ensuring dosage accuracy underscores its significance in pharmaceutical production. As the industry continues to advance, this machine remains a vital asset, driving the production of high-quality tablets that meet healthcare demands worldwide.

*** Technical parameter

|

Dies No. |

29 set |

|

Max. Production Capacity |

110000 pcs/h |

|

Max. Pressure |

100KN |

|

Max. Dia. of Tablet |

24mm |

|

Max. Depth of Filling |

24mm |

|

Max. Thickness of Tablet |

12mm |

|

Length of Upper/Lower Punching Bar |

115mm/133.4mm |

|

Rotary Speed |

5~21 r/min |

|

Motor |

5.5kw |

IPv6 network supported

IPv6 network supported