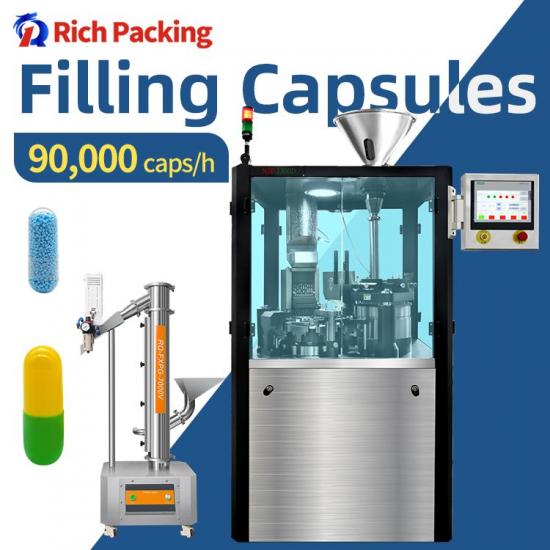

NJP 1500 Automatic Capsule Filling Machinery

Filling Capsules Machines Powder 1500D are very easy to clean, and zero dirt is one of its advantages, these are very environmentally friendly and very economically. This machinery can run efficiently from day morning to night under the conditions of continuous machinery, and 1500D can run with 0 noise. And all kinds of Fills capsules moulds are easily to change and have 0 deviation to ensure the quality of the capsules filled without any scratches or damage.

The adjust working process and ways of the gaps between the dosing disc and the sealing rings of the hard capsule Fills machines automatic. The gaps between the dosing disk and the sealing rings of the auto capsule Fills machine are from 0.03 to 0.08mm. When the powder pellets are too large, the interval can be adjusted to be larger. If the gaps are too mini, the resistance between the dosing disk and the sealing rings would increase. During the operation of the capsule Fills machines fully automatic, it is so necessary for adjusting the gaps when too much powder pellet leakage or excessive resistance be found.

Filling Capsules Machine Powder adjustment ways: loosen and remove the 5 screws in the baffle, loosen the set screw and then set nut, turn the 5 adjusting bolt evenly and carefully in turn to adjust the heights of sealing rings, check them with a feeler gauge For gaps, check the three to five measuring points.

*** Technical parameter

|

Production capacity |

90,000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

IPv6 network supported

IPv6 network supported