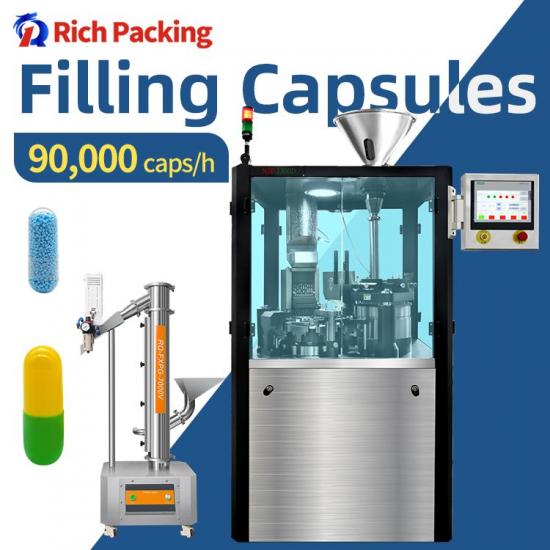

NJP 400C Capsule Filler Filling Machine

NJP 400C Powder Capsule Filling Machinery is easy to clean, low dirt is one of 400c’s strengths, this is very friendly environmentally or say economical. The machine can run efficiently from day to night under the condition of the continuous machine, and this can run with low noise. So, many kinds of filler rods are easily to change and have low deviation to ensure the qualities of the capsules without any damage or scratches.

The adjusting process and methods of the gap between the dosing disc and the sealing rings of the auto hard capsule fill machine. The gaps between the dose disk and the sealing rings of the capsule filling machine automatic is from 0.03 to 0.08mm. When the granule powder are big, the interval can be adjusted to be bigger. If the gaps are too mini, the resistances between the dosing disk and the sealing ring would be increased. During the operating of the capsule filling machine fully automatic, this is necessary to adjust the gaps when too many powder leakage or excessive resistance is found.

capsule automatic machine adjustment way: it is loosen and remove the five screws on the baffle, then loosen the set screws and the set nut, turn the five adjusting bolts carefully and evenly in turn to adjust the height of the sealing ring, check with feeler gauge for gaps, checking the three to five measuring points, the gaps at points shall be consistent, and ensure that the 5adjusting sleeves are in contact with the sealing rings.

*** Technical parameter

| Name |

400 C capsule filling machine Fully automatic |

|

capacity |

24,000 pcs /h |

|

Net weight of machine |

600 Kg |

|

Overall size of machine |

1000×710×1900(mm) |

|

Power |

380/220 V 50 Hz |

|

Total power |

3.5 KW |

IPv6 network supported

IPv6 network supported