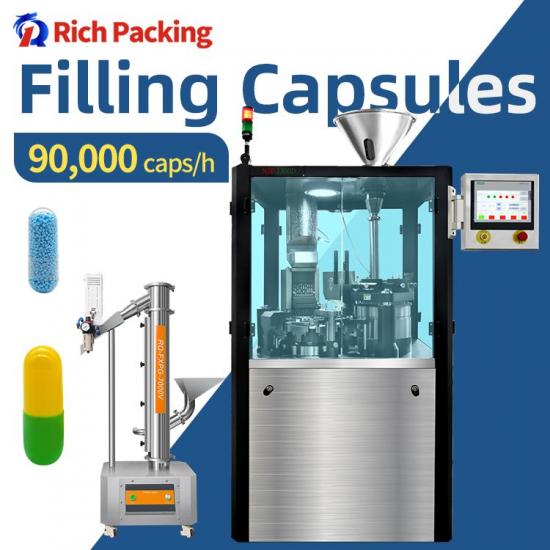

NJP 1500D Automatic Hard Capsule Filling Machinee of Rich Packing

capsule filler vacuum pump air pressure is a common systemic problem, that is, whether there is enough vacuum pressure to separate the capsule body from the capsule cap during the operation of the machine. Therefore, the user should check whether the capsule filler air pressure system meets the needs of the machine operation before using the capsule filler. , Such as whether the tightness is normal and whether the power is large enough.

At the same time, the user needs to check whether the capsule filler various stations are synchronized before the machine is turned on at full speed; it is also important to choose a mold that matches the capsule size. In addition, the normal operation of the capsule filler is also affected by other factors, such as the inappropriateness of the mold and the capsule , It may cause the capsule to freeze during the inoculation.

At this time, we should replace the mold or use tools to deal with the waste in the channel of the inoculation. In addition, sometimes it may happen that the capsule cannot enter the hole of the capsule filler capsule plate correctly. The reason may be that the capsule channel is not aligned with the space on the capsule plate, or the vacuum tube is not properly sealed, or the power of the vacuum pump is not enough. Proofread the mold, or clean the filter of the vacuum pump. Our RICH PACKING’s machine will not occur these problem, welcome to contact we RICH PACKING.

*** Technical parameter

|

Production capacity |

90,000 pcs/h |

|

Net weight of machine |

1,200Kg |

|

Overall size of machine |

900×870×1,950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Making rate |

Empty capsule 99.9% Full capsule 99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150 mm |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

VFD015 B21A |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

CH-30-1100W |

1 |

Dongli |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwandaojin |

|

Vacuum pump(wet) |

SK-0.5A |

1 |

Shanghai |

|

Dust collector |

XLJ Series |

1 |

Self-made |

IPv6 network supported

IPv6 network supported