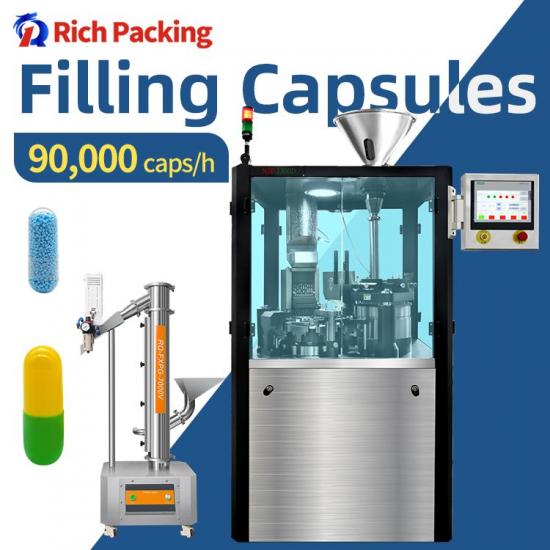

NJP 3800D High Speed Capsule Filling Machine By Rich Packing

The NJP-3800 capsule filler machine was designed by our team to meet the needs of high capacity capsule production. This type is the higher-speed model developed after the high-speed capsule filling model 2600. On the premise of fully meeting the GMP hygienic production requirements, we have upgraded the productivity per minute by more than 40% compared with NJP2600. Applications

The difference between NJP3800 D-model capsule making machine and 2600 C-model machine is mainly in several major aspects. The first one is the difference in appearance.

The pure metal sheet appearance has been upgraded to the frame structure like the car paint process to prevent users fingerprints and the oil stains from interfering with machine production.

The number of molds seeding holes on the capsule plate has also been upgraded to two rows, a total numbers of 27. With so many seeding holes, the output data can easily exceed 200,000 finished capsules in one hour.

Why choose ours NJP-3800C model? The capsule filling machine runs very stably, and the material of powder is loaded by starting and unloading which is similar to injection. The resulting advantages are that the amount of material added is very accurate, and it can achieve very good suppression of the powder spillage. The NJP-3800D capsule filling machine is complies with the GMP production standard. The parts and components used in the NJP 3800 are harmless to the human body and the biologically. Pharmaceutical and food industry safety are the first considerations for our machine production. The NJP-3800C full automatic capsule filling machine is suitable for filling the full size capsules, that is covering from #000 capsules to #5 capsules can be completed. This model of machine NJP-3800D has obtained six technological innovations and the number of creation patents.

*** Technical parameter

| Name | high speed capsule filling machine |

|

Production capacity |

228000 pcs/h |

|

Net weight of machine |

2200Kg |

|

Overall size of machine |

1395×1180×2200 |

|

Power |

380/220V 50Hz |

|

Total power |

10.5KW |

|

No.of segment bores |

27 |

|

Vacuum |

120m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BE11-3A0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3T42(3pcs)3T43(2pcs) |

5 |

Germany Siemens |

|

Frequency converter |

ATV320U40N4C |

1 |

Schneider |

|

Thermal relay |

3UA59 |

4 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

R57DRS100M4BES |

1 |

GermanySEW |

|

Cam |

RU-125DS-10 RU-100DS-6 |

2 |

Taiwan daojin |

|

Vacuum pump(wet) |

SK-2A |

1 |

Shanghai |

|

Dust collector |

XLJ Series |

1 |

Self-made |

|

Linear bearing |

LM12UU |

56 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM25UU |

16 |

Korea SAMICK |

|

Linear bearing |

LM50UU |

4 |

Korea SAMICK |

|

Plastic engineering bearings |

LIN-01-16 |

20 |

Germany Igus |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

2 |

Japan IKO |

|

Roller bearing |

CF16B |

3 |

Japan IKO |

|

Deep groove ball bearing |

CF20B |

2 |

JapanNSK |

IPv6 network supported

IPv6 network supported