NJP 400C Capsule Filling Machine Automatic

*** Technical parameter

| Name | Fully automatic 400 C capsule filling machine |

|

Production capacity |

24,000 pcs /h |

|

Net weight of machine |

600 Kg |

|

Overall size of machine |

1000×710×1900(mm) |

|

Power |

380/220 V 50 Hz |

|

Total power |

3.5 KW |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

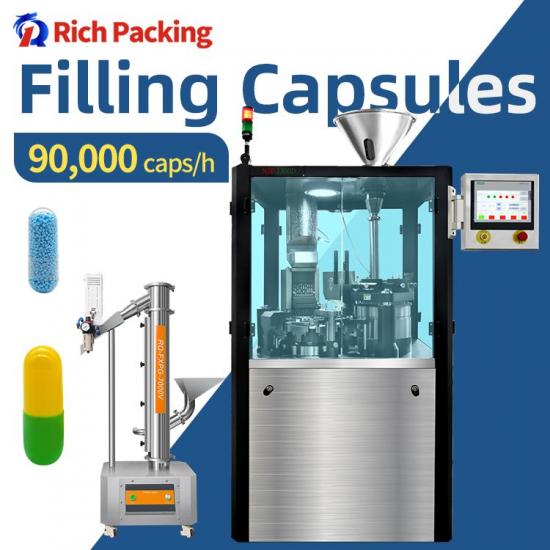

Now many pharmaceutical companies and industrial manufacturing companies use fully automatic capsule filling machines in their daily work, but many end customers do not know how to properly operate the fully automatic capsule filling machine? In fact, it is very simple to operate our Guangdong RICH PACKING capsule filling machine. The following is the simple process introduced in detail:

1. When running a piece of equipment, only by understanding its working principle can help the operator to better control the equipment. We have attached an operation manual to each machine that leaves the factory.

2. If you only purchased a single machine, then when using it, manually pour the products that need the capsule filling machine into the top feeding device. If equipped with a vacuum automatic hollow capsule feeding machine, the machine will automatically send the capsules into the feeding bin.

3. Our company's capsule filling machine adopts pneumatic valve feeding method on the powder material feeder, which can intelligently feed the machine faster and more accurately.

4. After starting the machine, the subsequent production process will be automatically completed by the machine, including a variety of processes: sowing capsules, dividing capsules, filling, rejecting waste and locking capsules, and finally the filled capsules are output.

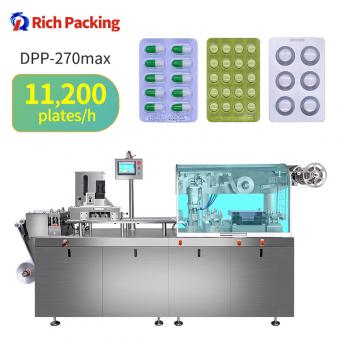

Guangdong RICH PACKING Co., Ltd. specializes in the production and sales of various types of capsule filling machines, automatic and semi-automatic counting machines, blister machines for capsule tablets, tablet presses, etc. The NJP series capsule filling machines produced by our factory adopt the original automatic capsules at home and abroad. The filling machine has been upgraded and improved, and its functions have reached the international level. I look forward to your inquiries and negotiations.

Complete Guide to Maintenance and Care Techniques: NJP-400C Capsule Filling Machine Automatic

In the fast-paced pharmaceutical industry, the quality and reliability of production equipment are critical to meeting stringent standards and maximizing efficiency. Among the essential machines in the manufacturing process, the NJP-400C Capsule Filling Machine Automatic stands out as a highly sophisticated tool for filling empty capsules with powders, granules, and other substances. This machine is particularly valuable in ensuring precision and speed during the capsule manufacturing process.

To maintain optimal performance and ensure long-lasting reliability, the automatic capsule filler machine must be properly maintained. Neglecting its upkeep can lead to costly repairs, reduced capsule filling productivity, and even compromised capsule quality. This guide offers an in-depth look at the best practices for maintaining and caring for the NJP Capsule Filling Machine, ensuring that it performs at its best for years to come.

Why Maintenance Matters for Capsule Filling Machines

The NJP-400C Capsule Filling Machine Automatic is designed to handle a variety of tasks related to capsule production. It efficiently separates, fills, seals, and ejects capsules. Despite its advanced technology, regular maintenance is essential to ensure the capsules machine runs smoothly. When properly maintained, this capsule making machine offers several benefits, including:

Increased Durability: Regular care ensures the longevity of key components, reducing the likelihood of costly breakdowns.

Improved Efficiency: Well-maintained machines perform better, reducing downtime and maximizing production efficiency.

Consistent Quality: Regular cleaning and calibration help ensure that each capsule is filled with the right amount of material, preserving the quality and integrity of the product.

Money Savings: Preventative maintenance is far less expensive than the cost of emergency repairs and replacements.

Given these benefits, it is essential for manufacturers to follow a detailed maintenance routine, tailored specifically for the NJP 400C Capsule Filling Machine.

Key Components of the NJP-400C Capsulator Machine Automatic

Before diving into maintenance techniques, it's very important to understand the key components that make up the NJP Capsule Machine. Proper knowledge of these components will help ensure that maintenance efforts are targeted and effective:

1. Capsule Feeding Mechanism: This is responsible for loading the empty capsules into the machine. It's vital to ensure this component operates smoothly to avoid jams or misfeeds.

2. Filling Station: The heart of the automatic gelatin capsule machine, the filling station is where the powders or granules are dispensed into the capsules. Regular machinery cleaning is essential to prevent contamination between different batches.

3. Dosing System: This precision filling system ensures the precise amount of material is filled into each capsule. Calibration is crucial for accuracy and consistency in the dosage.

4. Rejection System: After filling, any defective capsules (such as those that are over- or under-filled) are sorted out by the rejection mechanism. Ensuring this system works prevents defects from reaching the final product properly.

5. Machine Frame and Housing: The structure that houses all the components must be inspected for corrosion or damage. Routine checks help maintain the stability of the machine during high-speed operations.

6. Control Panel: The control panel regulates the settings for the entire process, including speed, dosing amount, and filling capacity. It is essential to keep the software up-to-date and the system properly calibrated.

Step-by-Step Maintenance Practices

Proper maintenance includes a series of actions that should be carried out daily, weekly, monthly, and annually. Below are the recommended maintenance practices for the NJP-400C Capsule Filling Machine Automatic:

Daily Maintenance

Clean the Filling Area: After each batch, clean the filling station, especially the filling needles and any other components that come in contact with the powder. This will prevent clogs and ensure that different materials do not mix.

Inspect the Empty Capsules Feeder: Check the capsule feeding mechanism for any jams or misalignments. Capsule misfeeds can cause operational delays, so keeping this area free of obstructions is essential.

Examine Parts for Wear: Inspect all belts, gears, and other moving parts for signs of wear. Lubricate wear components to reduce friction and prevent premature breakdowns.

Weekly Maintenance

Clean the Dosing System: Dust and powder buildup can cause irregularities in the filling process. Clean the dosing devices to ensure even and accurate powder distribution into the capsules.

Lubricate the Machine Components: Apply lubrication to all rotating parts, such as the cams, shafts, and gears. This reduces the risk of friction-induced wear, which can damage the machine.

Test the Capsule Rejection Mechanism: Ensure that the capsule rejection system is working correctly. Any defective capsules should be removed from the production line to maintain product quality.

Monthly Maintenance

Deep Clean the Capsule Feeder: Over time, small amounts of powder can accumulate in the capsule feeder. A thorough cleaning helps avoid misfeeds and jams.

Check the Calibration of Dosing Devices: The capsule filler machine automatic needs to be calibrated regularly to ensure the correct amount of material is dispensed into each capsule. Inaccurate dosing can result in product inconsistencies.

Inspect the Rejection System: This system should be cleaned and adjusted if necessary. Ensuring it is working at full capacity is vital for maintaining high-quality output.

Quarterly Maintenance

Conduct a Full Encapsulator Inspection: This includes inspecting the entire machine for signs of wear or corrosion. Check the electrical components, belts, seals, and other parts for any damage.

Examine Electrical Connections: Loose or worn electrical connections can lead to operational issues. Regularly check and tighten any electrical components as needed.

Check the Control Panel: Ensure it is functioning properly and that all settings are optimized for efficient production.

Annual Maintenance

Disassemble and Clean Thoroughly: Every year, disassemble the NJP Capsule Filling Machine for a more detailed cleaning. This is very important for areas that are hard to reach with routine cleaning.

Replace Worn Components: Parts such as seals, belts, and gears will naturally wear out over time. Replacing these parts annually ensures the machine operates at peak performance.

Recalibrate the System: Over time, minor discrepancies can develop in the machine's settings. Full recalibration ensures all components function as intended.

Troubleshooting Common Problems

Even with regular maintenance, problems may occasionally occur.. Here are a few common issues and potential solutions for the automatic encapsulation machine:

1. Problem: Capsule Jams

Solution: Ensure the feeding mechanism is aligned and clean. Jams can occur when capsules are not correctly oriented or when the feeding mechanism is obstructed.

2. Problem: Inaccurate Fillings

Solution: Check the dosing system for blockages or wear. Operators should perform calibration regularly to maintain filling accuracy.

3. Problem: Defective Capsules

Solution: Check the rejection mechanism to ensure it is functioning correctly. Defective capsules should be automatically rejected to guarantee product quality..

Why Choose Guangdong Rich Packing Machinery Co., Ltd.?

Guangdong Rich Packing Machinery Co., Ltd. has over 30 years of experience in designing and manufacturing high-quality packaging equipment, including the NJP-400C Capsule Filling Machine Automatic. Our products are trusted by over 4,320 customers globally, including major industry players like UCB and Robinson.

We provide full solutions tailored to your needs, including semi auto and automatic filling capsule machines. We uphold the principles of innovation, reliability, and customer satisfaction, providing comprehensive after-sales service, including installation, training, and technical support. In addition, we offer a three-year spare parts warranty and a one-year free supply of consumable parts.

At Rich Packing, we understand the importance of precision in pharmaceutical and Packaging Machinery manufacturing. Our capsule filler machine automatic models are designed for maximum efficiency and accuracy, and we offer full technical support to ensure your equipment runs smoothly.

Conclusion

The NJP 400C Capsule Filling Machine Automatic is a critical piece of pharma equipment in pharmaceutical manufacturing. By following the recommended maintenance plan above and addressing common issues early, you can ensure your automatic gelatin capsule machine continues to operate at its best performance. Regular maintenance not only extends the lifespan of the equipment but also ensures that the capsules meet better quality standards.

Whether you're a small business or a large-scale manufacturer, investing in proper maintenance for your capsule making machine will pay off in the long run, improving productivity, quality, and profitability.

IPv6 network supported

IPv6 network supported