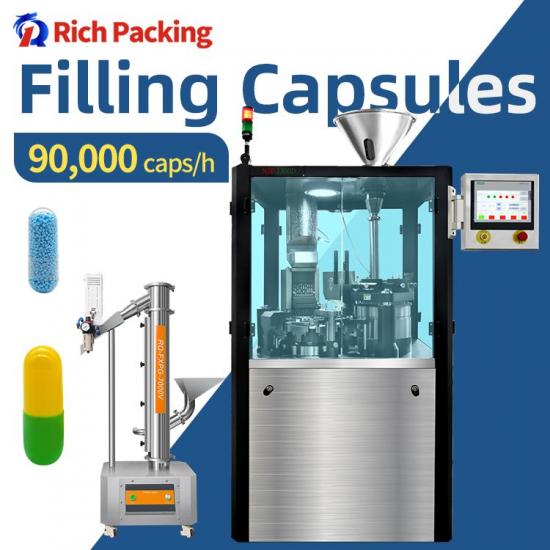

NJP-400C Laboratory Automatic Capsule Filling Machine

The NJP-400C capsule filling machine introduces the electronic stepless polishing process. Through this technology, the surface of the mold is extremely polished, making it extremely smooth. This process can improve the surface quality of the mold at a microscopic level, reducing the chance of friction and adhesion.

One of the biggest benefits of the electronic stepless polishing process is the improved operational stability of the equipment. Since the mold surface is very smooth, materials cannot adhere to it, so the filling process is more continuous and uniform. This helps reduce scrap rates, improve production efficiency and ensure each capsule is accurately filled to meet quality standards.

Traditional filling machines require frequent mold cleaning and replacement to maintain equipment performance. The NJP-400C capsule filling machine using electronic stepless polishing technology greatly reduces these maintenance costs. The smooth mold surface reduces mold wear, extends the service life of the mold, and reduces the frequency of maintenance.

Ultimately, the electronic stepless polishing process of the NJP-400C capsule filler helps improve product quality. Each capsule is evenly filled and the drug dose is accurate. This is crucial for pharmaceutical companies as it ensures that the drugs produced are of high quality and meet regulatory standards.

The electronic stepless polishing process of the NJP small capsule filling machine represents the pharmaceutical industry's continuous pursuit of technological innovation. This technology eliminates material adhesion problems by improving the smoothness of the mold surface, improves the operational stability of the equipment, reduces maintenance costs, and improves product quality. As a modern solution, the NJP-400C capsule filling machine will continue to play a key role in the pharmaceutical industry, ensuring high-quality capsule products.

*** Technical parameter

| Name | Fully automatic 400 capsule filling machine |

|

Production capacity |

24,000 pcs /h |

|

Net weight of machine |

600 Kg |

|

Overall size of machine |

1000×710×1900(mm) |

|

Power |

380/220 V 50 Hz |

|

Total power |

3.5 KW |

IPv6 network supported

IPv6 network supported