RQ-16R Automatic Capsule Tablet Counting Machine Line By Rich Packing

With the development of the economy and the concentration of industrialization, the bottling line or the counting line packaging machine has become an indispensable production machine in the pharmaceutical industry. In the context of increasing applications in the industry, the market continues to put forward higher standard requirements for the digital thread. Driven by the technological innovation of our Guangdong RICH PACKING, the matching product line machinery types are becoming more and more diversified, and the intelligent and efficient counting line has become the main force of pharmaceutical packaging machinery.

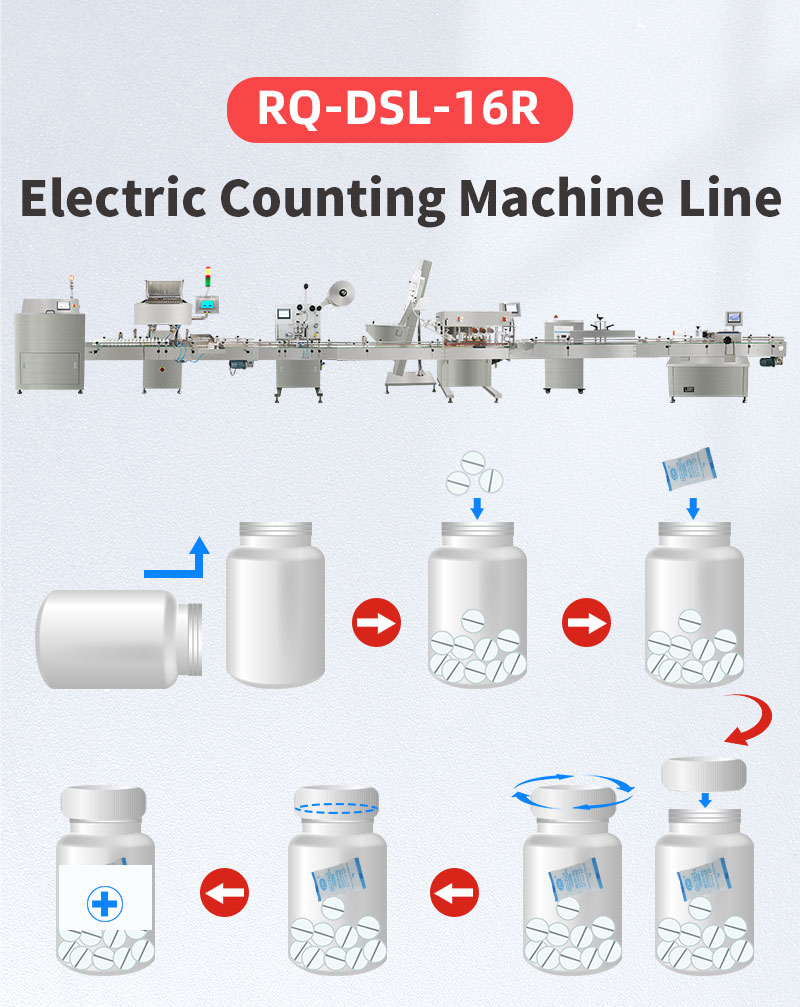

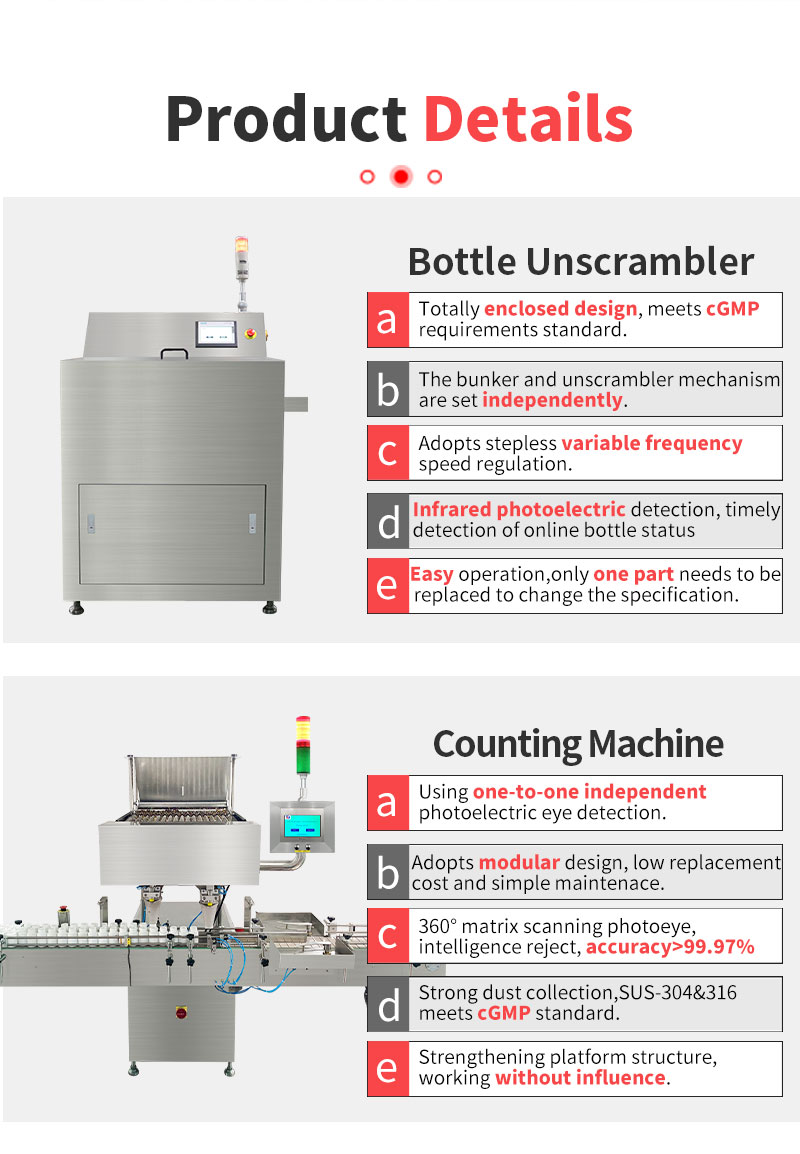

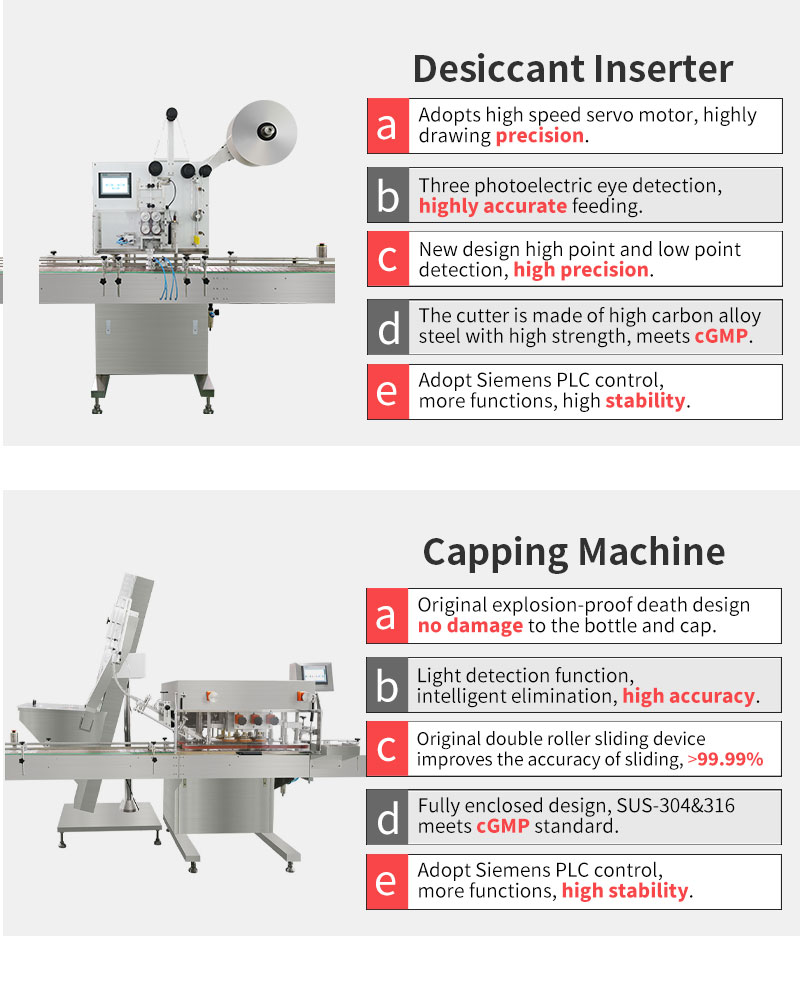

The purpose of counting thread is mainly aimed at reducing the manpower of workers in the pharmaceutical industry, increasing the speed of production, in order to achieve the purpose of improving production efficiency. Such as capsules and tablets, a large number of manufacturers require manual counting and packaging. With the emergence of intelligent high-speed counting line, it fully meets the needs of the rapid development of the market and replaces manual labor as a whole. It integrates bottle unscrambler, counting machine, dryer, capping machine, labeling machine, and sealing machine into one line. As a result, the scale of using several threads in the packaging industry has become wider and wider.

The design concept of the counting line is advanced, achieving automation and intelligence, and completing the addition of output value, improving quality, cutting costs and reducing environmental pollution. It is the highest manifestation of the automation level of the counting line packaging machinery. The digital thread has been upgraded to a new generation of production tools that extend the physical and intellectual abilities of workers, and it is the main means to complete production automation and intelligence.

*** Technician Parameters

|

Model |

RQ-DSL-16R Counting Line |

|

vibration groove tracks |

16 lane |

|

Production capacity |

200000 ~ 360000grains/h |

|

accuracy rate |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

Applicable target |

Tablet:Φ3~25mm ,pill:Φ3~20mm, |

|

Applicable bottle type |

Φ25~75mm round and square bottle, height ≤240 mm |

|

voltage |

AC380V 3P50/60HZ |

|

power |

2.2KW |

|

pressure |

0.4~ 0.6Mpa |

|

Air consumption |

120L/min |

|

Hopper capacity |

45L |

|

weight |

650kg |

|

Outline dim.(mm) |

1200×1550×1750mm |

IPv6 network supported

IPv6 network supported