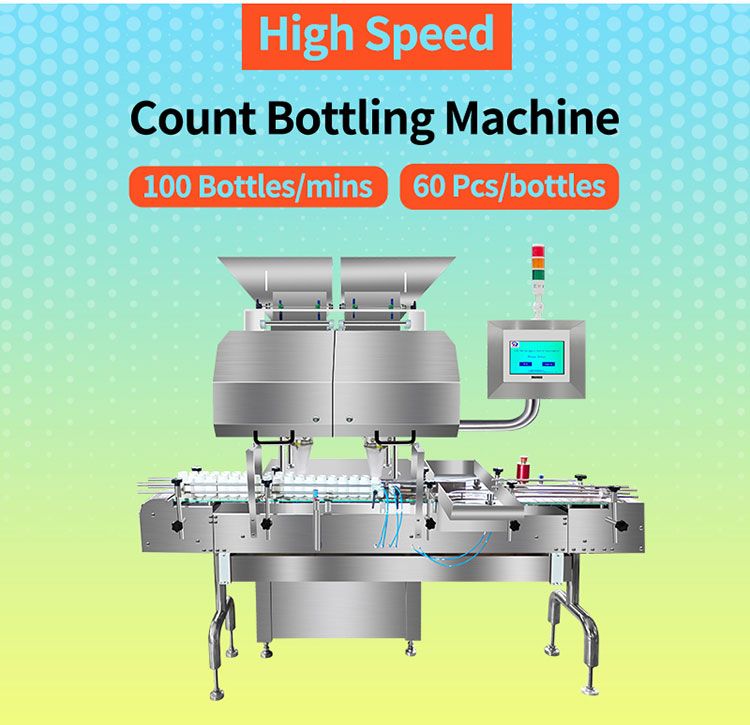

16 Lane High Speed Capsule Tablet Counting Machine By Rich Packing

With the rapid development of the economy and the rapid development of the human society, the requirements for counting counter productivity are also very high. So it is the same thing in our RICH PACKING’s pharmaceutical packaging industry. Many pharmaceutical and packing companies also take a lot of energy and time on productivity. Then the automatic electronic capsules tablets counting machine came into being.

Counting counter machine’s vibration frequency is higher than that of the ordinary machines, and it is quite relatively prepared for the uniformity of the size and weight of the pharmaceutical particles. It is quite convenient for the factory operator to uniformly pack during packaging, because the overall efficiency is very high.

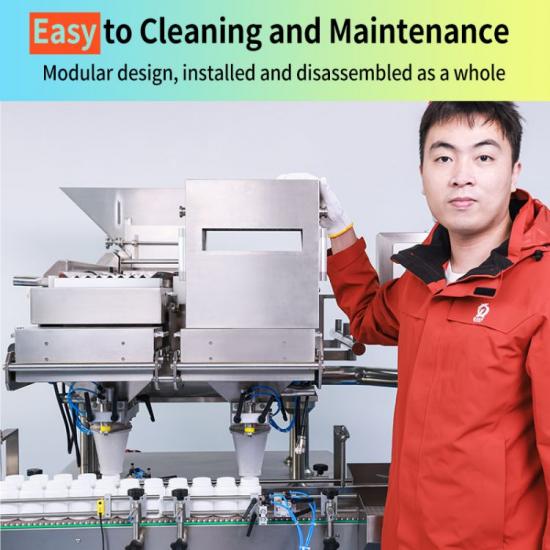

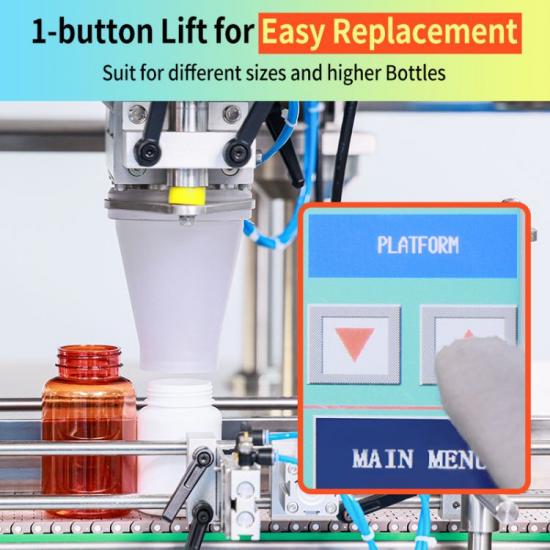

So these are the main reasons that there are many pharmaceutical manufacturers like. The materials of this automatic electronic capsules tablets counting machine has also become better and better, and it has become more convenient in the range of maintenance. It is quite important for the many front-line operators. Like this greatly reduces relieved work pressure and released working time. This time the height of our counting production line is still very ergonomic, so let these our technicians also do a lot of experiments to make many changes, so that the progress will not feel very tired, and the counting efficiency will naturally be improved greatly.

We RICH PACKING hope that our company's capsule counting machine products will be enjoyed by more and more customers in the national and the oversea market, and we will also actively utilize the good advantages of counting technology to introduce new ones continuously. Let more and more enterprise customers get higher counting production efficiency from it.

*** Technical parameter

|

Model |

RQ-DSL-16H |

|

Vibration groove tracks |

16 lane |

|

Production capacity |

260000 - 460000 grains/h |

|

Accuracy rate |

>99.98% |

|

Filling range |

1~ 9999 pcs |

|

Applicable target |

Tablet:Φ3~25 mm ,pill:Φ3~20 mm, |

|

Applicable bottle type |

Φ25~110 mm round and square bottle, height 30-240mm |

|

Voltage |

AC 380V 3P 50/60HZ |

|

Power |

2.5 KW |

|

Pressure |

0.45~ 0.7 Mpa |

|

Air consumption |

200 L/min |

|

Hopper capacity |

80 L |

|

weight |

900 kg |

|

Outline dim.(mm) |

1300×1950×1800 mm |

*** Configuration List

|

No. |

Item |

Specification |

Qty. |

Manufacturer |

|

1 |

Count Photoelectric Sensor (Receive) |

N24.5R |

16 |

RQ132 |

|

2 |

Count Photoelectric Sensor (Emit) |

N24.5E |

16 |

RQ132 |

|

3 |

Valve Group |

M4SB10-M5-6 |

2 |

Japan CKD |

|

4 |

Filtrate Regulator |

FR500 |

1 |

Taiwan SHAKO |

|

5 |

PLC Group |

FP∑-C32TH FPO-E16YT |

1 |

Japan Panasonic |

|

6 |

Touch Screen |

GE4408W |

1 |

Japan Pro-face |

|

7 |

Cable Diffuse Sensor |

QS18VN6DB |

3 |

USA.BANNER |

|

8 |

AC Contactor |

GMC-9 |

1 |

Korea LG |

|

9 |

DC Contactor |

GMD-9 |

3 |

Korea LG |

|

10 |

Thermal Overlood Relay |

GTH-22/3 |

1 |

Korea LG |

|

11 |

Count Cylinder |

DSN-10-55- |

16 |

Germany FESTO |

|

12 |

Position Cylinder |

SDA20-10 |

4 |

AIRTAC |

|

13 |

Control Box |

131200000 |

1 |

Germany MECANO |

|

14 |

Directive Signal Light |

AL6M-P |

3 |

Japan IDEC |

|

15 |

Button Switch |

ABW310EG |

1 |

Japan IDEC |

IPv6 network supported

IPv6 network supported