ZP 29D Tablet Making Rotary Tablet Press Machine

The abundant application of this type of GMP-compliant tablet pressing machine rotary 29D is the dual press type, and the expected highly output is super doubled to 75,000 tablets in one hour, which is extremely effective and has very complete functions.

The type 29D perfectly complies with the production management rules of ISO, and the austenitic metal material is abundantly used for the inside and outside of the machine.

The material workshop is fully applied with non-organic substances to successfully isolate it from the other machines, and the independence of the machine is very good.

The adjustment of the opium machine 29D can be tested by rotating the hand wheel, and the scale display accuracy to the level of one-tenth of a mm fully illustrates the accuracy of the 29D.

The good result of this precise details are that the quality and composition of the finished tablets produced is very stable.

This type of machine tableting 29D has super intelligence that is highly similar to intelligent like human AI, and can automatically protect and maintain by itself well.

A regular quantitative timing refueling device that intelligently detects the quantity of oil is used, so that each drop of lubricating oil is added just right.

These models have a keen overload protection fixing device, the timely alarm and automatic shutdown when overloaded, 29D does not shake during the running progress.

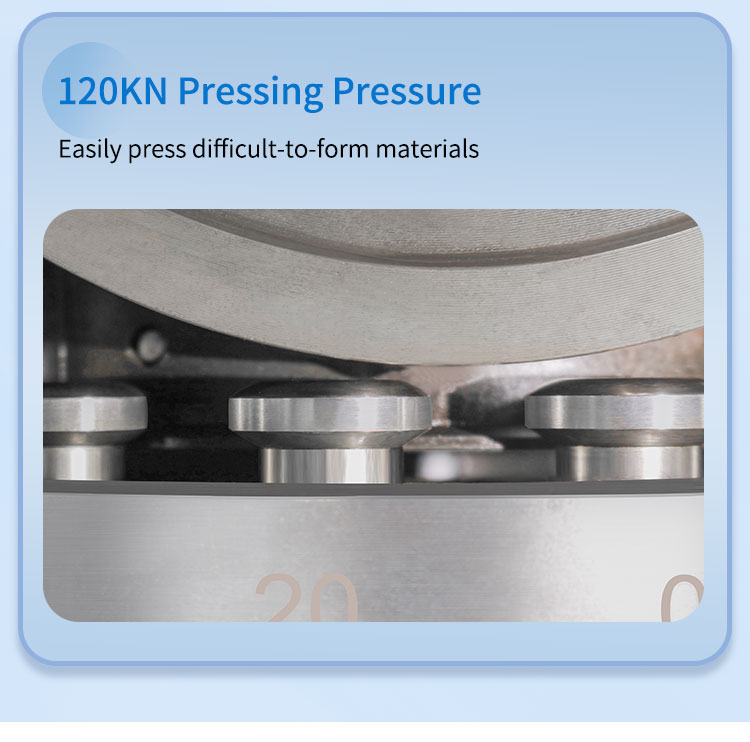

Every mold of the tablet press machine rotary always keeps running at the same concentrically, so that the upper and middle and the lower molds will never collide.

The molds have been calibrated and polished for a very long time by our skilled workers, and it is very smoothly to ensure that the materials will not stick to the molds.

Our 29D rotary tablet press can be customized in kinds of different shapes, and with different company LOGO you want or text shapes, which perfectly meets the user’s customized requirements for finished tablets.

Technical parameter

|

Dies No. |

29 set |

|

Max. Production Capacity |

75000 pcs/h |

|

Max. Pressure |

100KN |

|

Max. Dia. of Tablet |

25mm |

|

Max. Depth of Filling |

24mm |

|

Max. Thickness of Tablet |

12mm |

|

Dia. Of Middle Die |

Ф38.1mm |

|

Length of Upper/Lower Punching Bar |

115mm/133.4mm |

|

Dia.of Upper/Lower Punching Bar |

Ф25.4mm |

|

Rotary Speed |

5~21 r/min |

|

Motor |

5.5kw |

|

Weight of Machine |

1600kg |

|

Outline Dim. |

1040×910×1690mm |

|

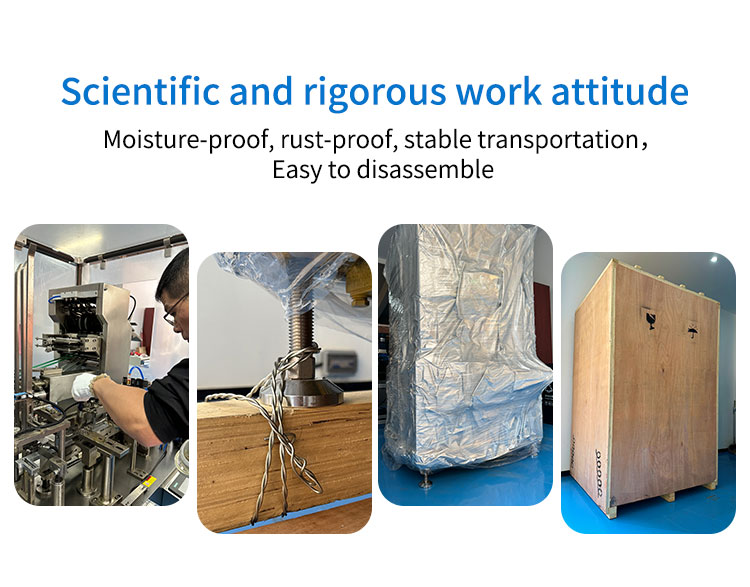

Packing Size |

1340×1100×1960mm |

|

Packing size of Dust Collector |

960×620×1460 mm |

Configuration List

|

Item |

Specification and Model |

Manufacturer |

|

Overload protector |

Self design |

Self manufacture |

|

Intelligent lubrication system |

American BIJUR DELIMON |

American BIJUR DELIMON |

|

Frequency converter |

VFD037B43B |

Taiwan Delta |

|

AC contactor |

3TB40 22-OXMO |

Germany Siemens |

|

Relay |

MY-2NJ MY-4NJ |

Japan Omron |

|

Upper and lower pressure wheel |

GCr15 |

Self manufacture |

|

Upper rail guide |

GCr15 |

Self manufacture |

|

Turntable |

HT250 |

Self manufacture |

|

Air switch |

DZ108 |

Tengen |

|

Hopper |

1Cr18Ni9Ti |

Self manufacture |

|

Scale hand wheel |

Sensitivity:0.1mm |

Shanghai Lichao |

|

Motor |

Y112M-4 |

Shanghai Lichao |

|

Shell |

S304 |

Thickness 1.5mm |

|

Glass door |

organic glass |

Thickness 15mm |

IPv6 network supported

IPv6 network supported