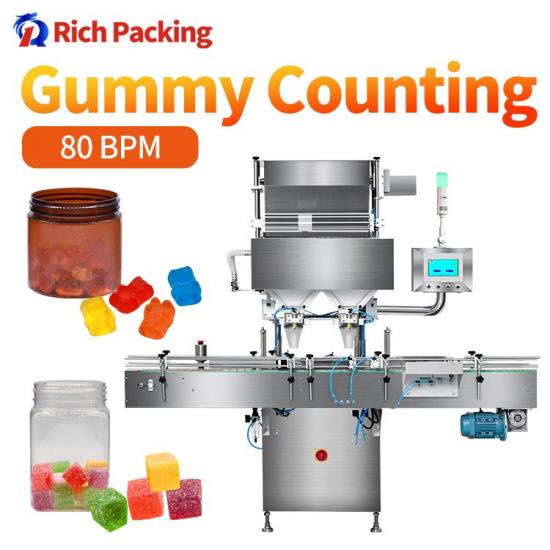

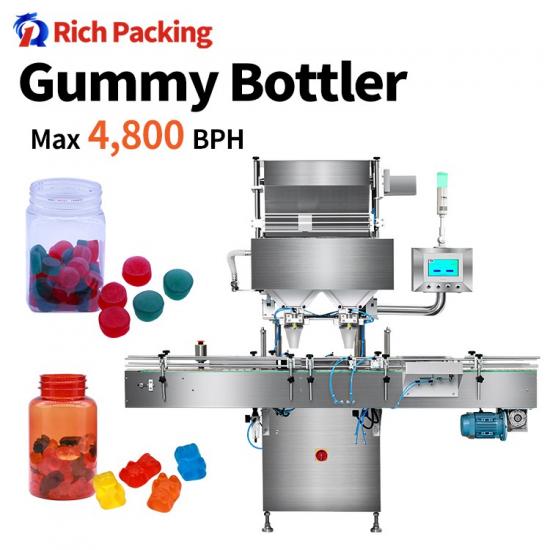

Counting Sweets Candy Gummy Counter Machine By Rich Packing

Our Guangdong RICH PACKING intelligent automatic counting machine is specially designed for materials with sticky surfaces. Especially for the most popular western countries viscous gummy bottling bags have been patented and upgraded solutions, including the most representative gummy bears, sugar cubes on the surface, and coated candies with oil on the surface.

The advantages of our Guangdong RICH PACKING packaging fudge counting machine:

The machine has a built-in intelligent production management system, which greatly improves the production capacity of bottling and bagging;

The hopper is equipped with a feeding cylinder device to help the separation of the fudge, which effectively helps the fudge to obtain a relatively loose distribution before entering the vibration tank;

Compared with ordinary machines, the vibration groove is sprayed with Teflon material, which makes the candy move very smoothly without lag.

The blanking device is made of PTFE, which meets the GMP standard and will not be blocked at the outlet;

The bottling mouth adopts a highly sensitive cylinder vibration blanking technology and device, and the bottle will never be blocked when the soft candy is bottled and bagged;

The above various devices and counting devices for improving gummy bears counting machine help users reduce the dependence on labor and greatly save costs; make all links of packaging closely connected, accurate counting, saving time and effort; automatic adjustment through PLC intelligent system can be flexibly adjusted Fudge products of all sizes, shapes and textures, to meet a variety of packaging formats.

*** Technical parameter

|

Model |

RQ-DSL-16R |

|

vibration groove tracks |

16 lane |

|

Production capacity |

200,000 ~ 360,000 grains/h |

|

accuracy rate |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

Applicable target |

Tablet:Φ3~25 mm ,pill:Φ3~20 mm, |

|

Applicable bottle type |

Φ25~75 mm round and square bottle, height ≤240 mm |

|

voltage |

AC380V 3P 50 / 60HZ |

|

power |

2.2 KW |

|

pressure |

0.4~ 0.6 Mpa |

|

Air consumption |

120 L/min |

|

Hopper capacity |

45 L |

|

weight |

650 kg |

|

Outline dim.(mm) |

1200×1550×1750 mm |

*** Configuration List

|

No. |

Item |

Specification |

Qty. |

Manufacturer |

|

1 |

Count Photoelectric Sensor (Receive) |

N24.5R |

16 |

Lattine |

|

2 |

Count Photoelectric Sensor (Emit) |

N24.5E |

16 |

Lattine |

|

3 |

Valve Group |

M4SB10-M5-6 |

2 |

Japan CKD |

|

4 |

Filtrate Regulator |

FR500 |

1 |

Taiwan SHAKO |

|

5 |

PLC Group |

FP∑-C32TH FPO-E16YT |

1 |

Japan Panasonic |

|

6 |

Touch Screen |

GE4408W |

1 |

Japan Pro-face |

|

7 |

Cable Diffuse Sensor |

QS18VN6DB |

3 |

USA.BANNER |

|

8 |

AC Contactor |

GMC-9 |

1 |

Korea LG |

|

9 |

DC Contactor |

GMD-9 |

3 |

Korea LG |

|

10 |

Thermal Overlood Relay |

GTH-22/3 |

1 |

Korea LG |

|

11 |

Count Cylinder |

SCPS2-1030 |

16 |

Japan CKD |

|

12 |

Position Cylinder |

SDA20-10 |

4 |

AIRTAC |

|

13 |

Control Box |

131200000 |

1 |

Germany MECANO |

|

14 |

Directive Signal Light |

AL6M-P |

3 |

Japan IDEC |

|

15 |

Button Switch |

ABW310EG |

1 |

Japan IDEC |

IPv6 network supported

IPv6 network supported