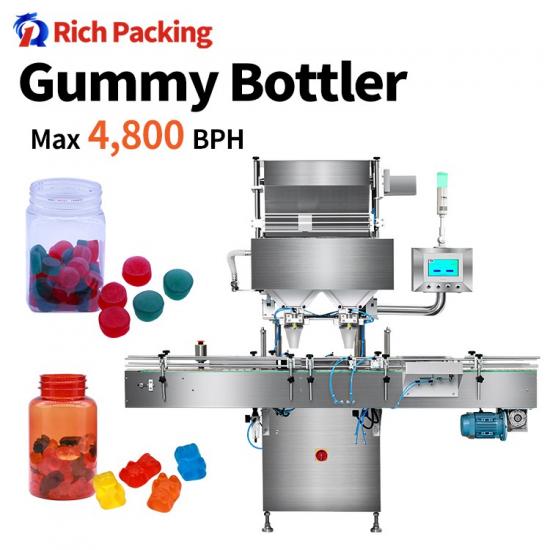

Automatic Counting Machine For Candy Gummy

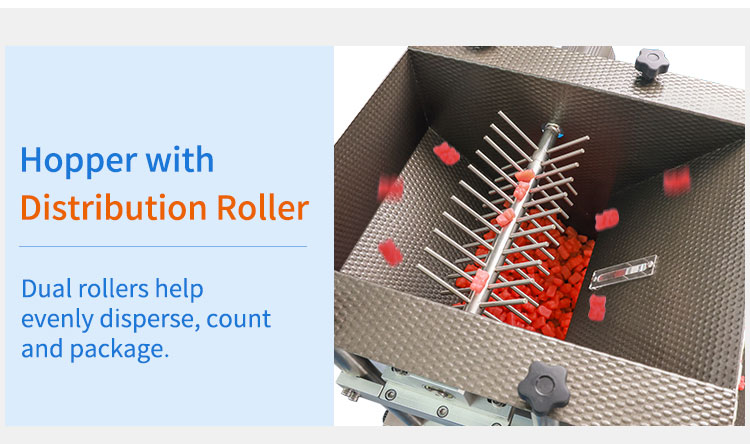

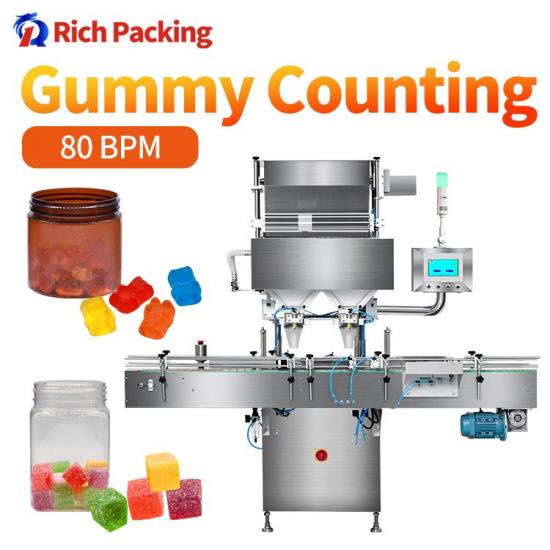

automatic 8 lane electronic counter machinery for candy gummy is accurate in counting and bottling and it can be operated rapidly and quite intelligently. 8D counting machine totally meets the standard rules of GMP. It is a new creative equipment which can run accurately and stably and this model of counter machine is the seventh generations product in our RICH PACKING company. It is playing a significant roles in the accurate counting and canning at the high speed.

All machine parts of the automatic electronic counter machinery for candy gummy that people can touch or the materials can touch are safe and totally meets the standards rules of cGMP.

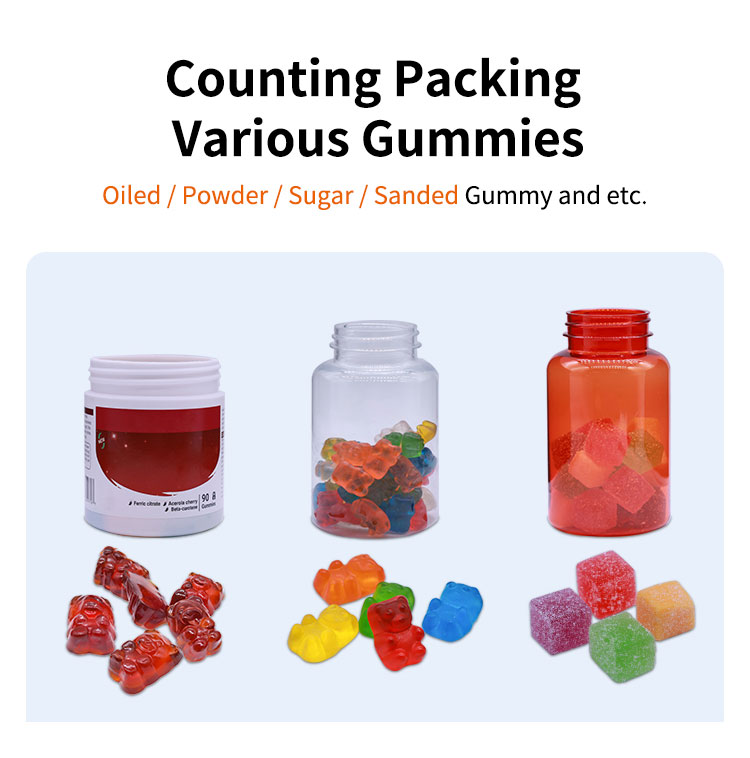

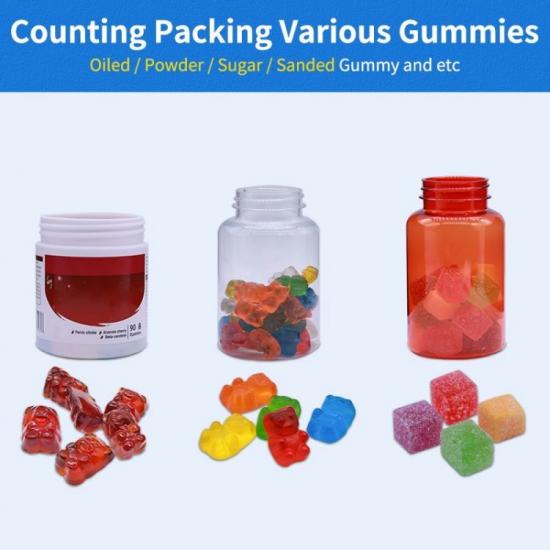

All kinds of raw materials can be available no matter what color the material is and what size the material is.

Its scientific design ensures the 0 electromagnetic interference in 8D counting machine and 0 signal fault of the inner equipment due to its dust prevention system.

Not only just zero dust but also 8D counting machine can be freely and easily cleaned and maintained by people at any time.

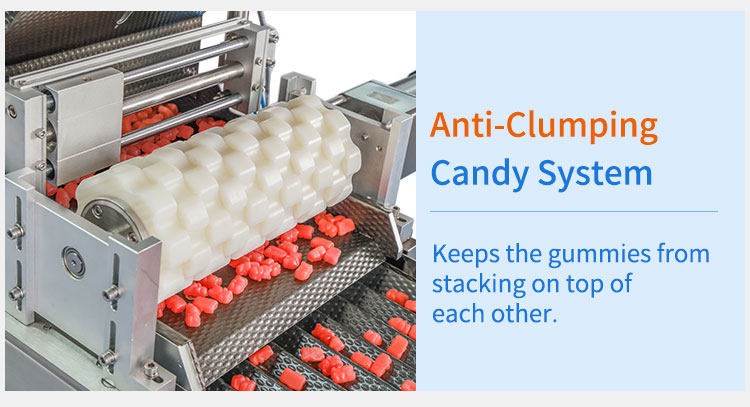

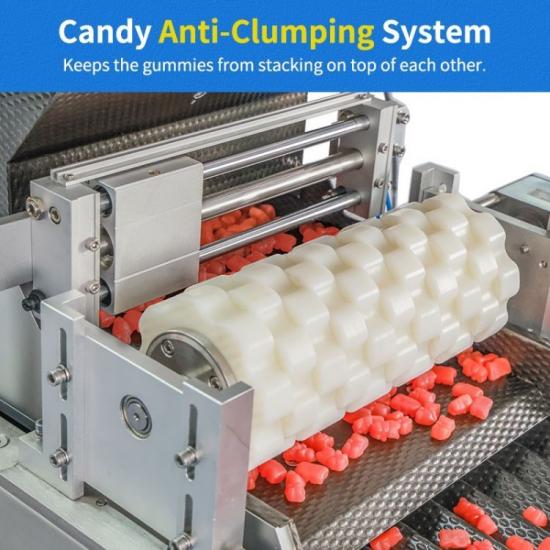

This automatic electronic counter machinery for candy gummy has higher accuracy rate of more then 99.97% than the standards of the counting machinery industry to meet the high accuracy needs of the users. 8D counting machinery utilizes three-stage vibrator to ensure the stable vibration especially to ensure the smooth running of the irregular material to ensure the precision.

It utilizes technology of the self-made electric counting and infrared ray to scan with total 360 degree to check totally to ensure the precision.

*** Technical parameter

|

Model |

RQ-DSL-8D |

|

Vibration groove tracks |

8 lane |

|

Production capacity |

55 bottles per minute |

|

Accuracy rate |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

Applicable bottle type |

Φ25~75mm round and square bottle, height ≤240 mm |

|

Voltage |

AC380V 3P 50/60HZ |

|

Power |

1.5KW |

|

Pressure |

0.4~0.6Mpa |

|

Air consumption |

105L/min |

|

Hopper capacity |

25L |

|

Weight |

405kg |

|

Outline dim.(mm) |

1100×1400×1800mm(L*W*H) |

*** Configuration List

|

No. |

Item |

Specification |

Qty. |

Manufacturer |

|

1 |

Count Photoelectric Sensor (Receive) |

N24.5R |

8 |

Lattine |

|

2 |

Count Photoelectric Sensor (Emit) |

N24.5E |

8 |

Lattine |

|

3 |

Valve Group |

M4SB10-M5-6 |

1 |

Japan CKD |

|

4 |

Filtrate Regulator |

FR500 |

1 |

Taiwan SHAKO |

|

5 |

PLC Group |

FP∑-C32TH FPO-E16YT |

1 |

Japan Panasonic |

|

6 |

Touch Screen |

GE4408W |

1 |

Japan Pro-face |

|

7 |

Cable Diffuse Sensor |

QS18VN6DB |

3 |

USA.BANNER |

|

8 |

AC Contactor |

GMC-9 |

1 |

Korea LG |

|

9 |

DC Contactor |

GMD-9 |

3 |

Korea LG |

|

10 |

Thermal Overlood Relay |

GTH-22/3 |

1 |

Korea LG |

|

11 |

Count Cylinder |

SCPS2-1030 |

8 |

Japan CKD |

|

12 |

Position Cylinder |

SDA20-10 |

4 |

AIRTAC |

|

13 |

Control Box |

131200000 |

1 |

Germany MECANO |

|

14 |

Directive Signal Light |

AL6M-P |

3 |

Japan IDEC |

|

15 |

Button Switch |

ABW310EG |

1 |

Japan IDEC |

IPv6 network supported

IPv6 network supported