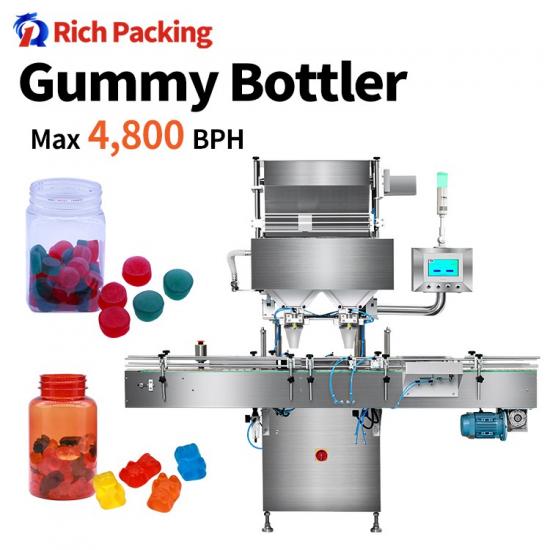

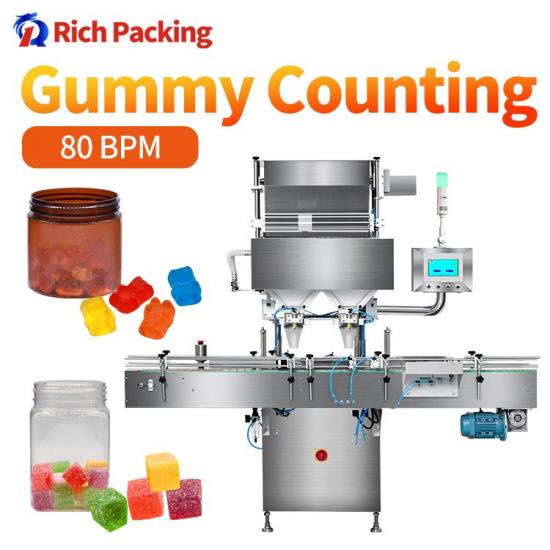

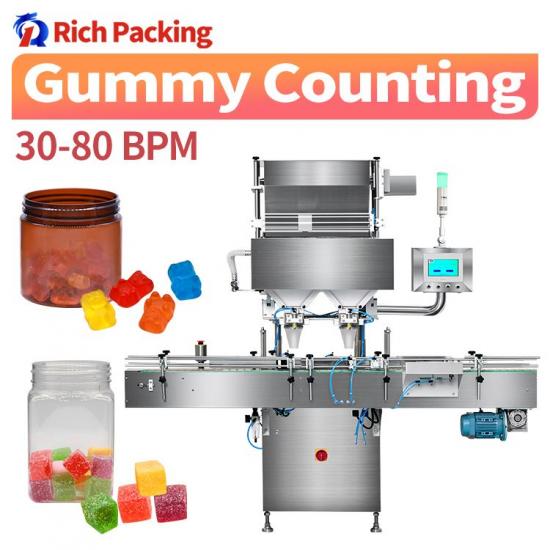

DSL 16 Lane Gummy Candy Counter Counting Machine

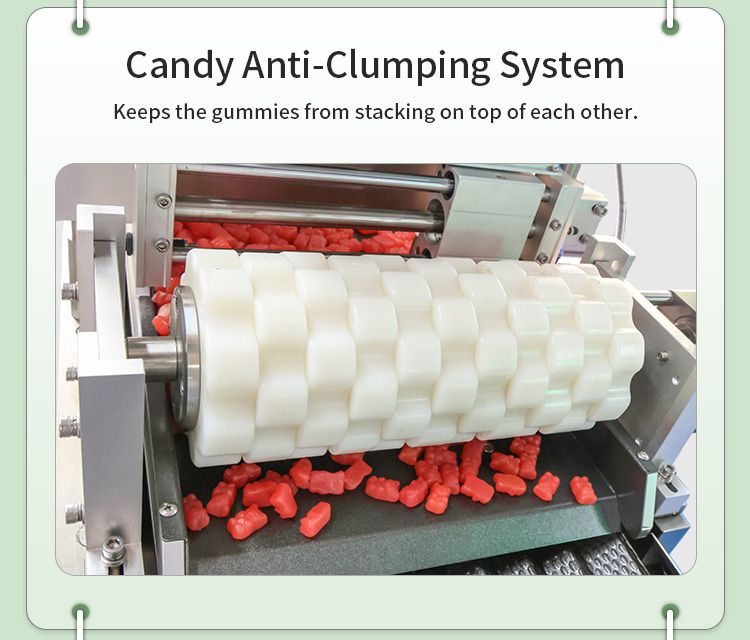

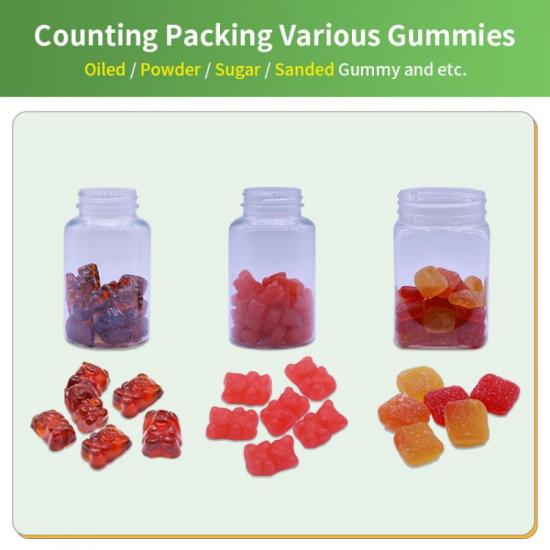

The fully active electronic automatic candy gummy counting machine produced by Guangdong RICHPACKING. This is the high intelligent and high accurate fully active capsule counting machine and the newest style capsule creation machinery, that can actively complete any number of accurate counting and filling bottling tasks. For example, the compensation counting of the meandering trajectory of this machine prevents the traditional alarm or the twisting type of counting tablets from the disadvantages of low accuracy.

Although the counting machine is mainly the machine for counting the medicines or the solid foods, the up and down of its technological contents and the accuracy rate of counting will have a serious impact on the quality of the pharmaceuticals and the power of pharmaceutical production.

Today, with the fast development of the science and the technology, it is the inevitable choice for pharmaceutical and food companies to install high tech automatic counter counting machines. In order to meet the production needs of pharmaceutical and candy food companies, this gummy and candy counting machine manufacturers need to implement technological innovations from time to time to promote the industrial transformation and the upgrading.

*** Why you should choose ours’ DSL 16R electronic gummy candy counting machine? The electronic counting machine industry is a main industry in the pharmaceutical bottling equipment industry. Under the background of the fast development of the pharmaceutical and food packaging industry, the counting machine has many technical meaning, high added value and the large development space. It is the pharmaceutical bottling and counting machine, and is the rising star of the industry, Competitiveness advantages has also been greatly improved.

During this science period, the high tech automating tablet capsule counting machine equipment became the pride of professional development.

*** Technical parameter

|

Model |

RQ-DSL-16R |

|

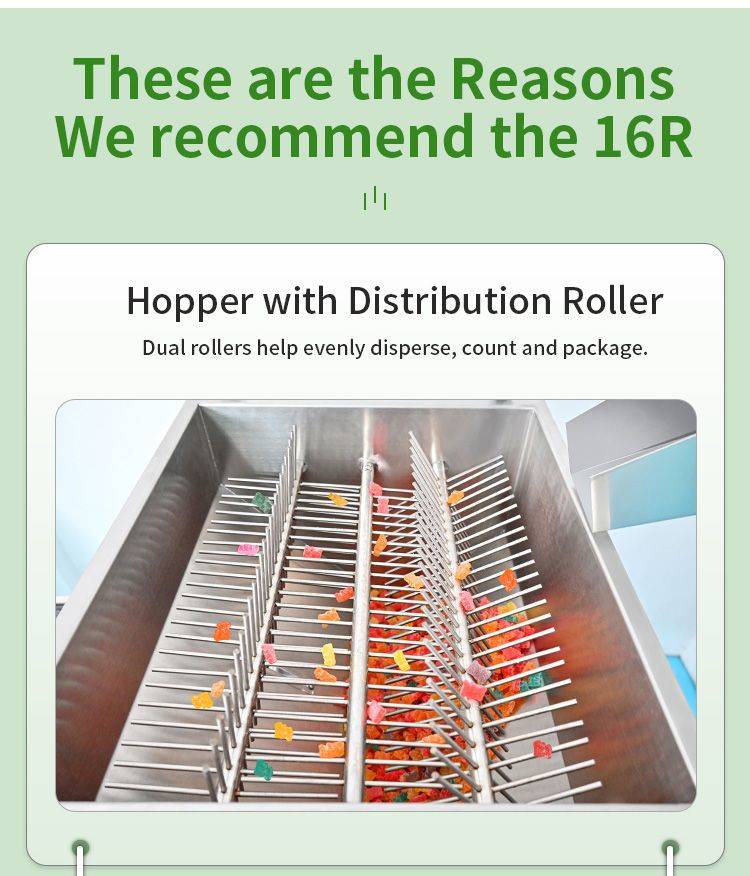

vibration groove tracks |

16 lane |

|

Production capacity |

25-80 bottles/min |

|

accuracy rate |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

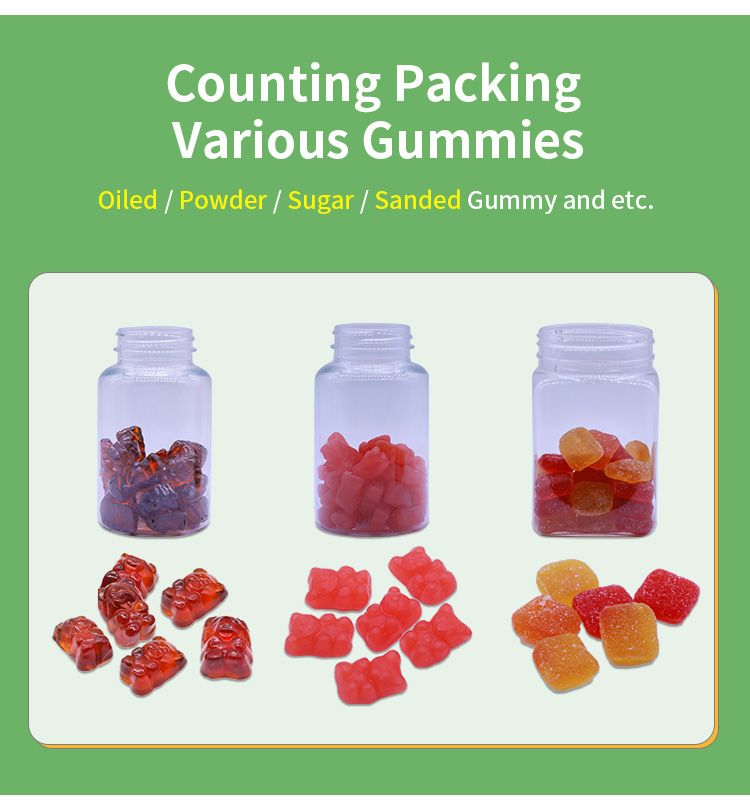

Applicable target |

Tablet:Φ3~25 mm ,pill:Φ3~20 mm, |

|

Applicable bottle type |

Φ25~75 mm round and square bottle, height ≤240 mm |

|

voltage |

AC380V 3P 50 / 60HZ |

|

power |

2.2 KW |

|

pressure |

0.4~ 0.6 Mpa |

|

Air consumption |

120 L/min |

|

Hopper capacity |

45 L |

|

weight |

650 kg |

|

Outline dim.(mm) |

1200×1550×1750 mm |

*** Configuration List

|

No. |

Item |

Specification |

Qty. |

Manufacturer |

|

1 |

Count Photoelectric Sensor (Receive) |

N24.5R |

16 |

Lattine |

|

2 |

Count Photoelectric Sensor (Emit) |

N24.5E |

16 |

Lattine |

|

3 |

Valve Group |

M4SB10-M5-6 |

2 |

Japan CKD |

|

4 |

Filtrate Regulator |

FR500 |

1 |

Taiwan SHAKO |

|

5 |

PLC Group |

FP∑-C32TH FPO-E16YT |

1 |

Japan Panasonic |

|

6 |

Touch Screen |

GE4408W |

1 |

Japan Pro-face |

|

7 |

Cable Diffuse Sensor |

QS18VN6DB |

3 |

USA.BANNER |

|

8 |

AC Contactor |

GMC-9 |

1 |

Korea LG |

|

9 |

DC Contactor |

GMD-9 |

3 |

Korea LG |

|

10 |

Thermal Overlood Relay |

GTH-22/3 |

1 |

Korea LG |

|

11 |

Count Cylinder |

SCPS2-1030 |

16 |

Japan CKD |

|

12 |

Position Cylinder |

SDA20-10 |

4 |

AIRTAC |

|

13 |

Control Box |

131200000 |

1 |

Germany MECANO |

|

14 |

Directive Signal Light |

AL6M-P |

3 |

Japan IDEC |

|

15 |

Button Switch |

ABW310EG |

1 |

Japan IDEC |

IPv6 network supported

IPv6 network supported