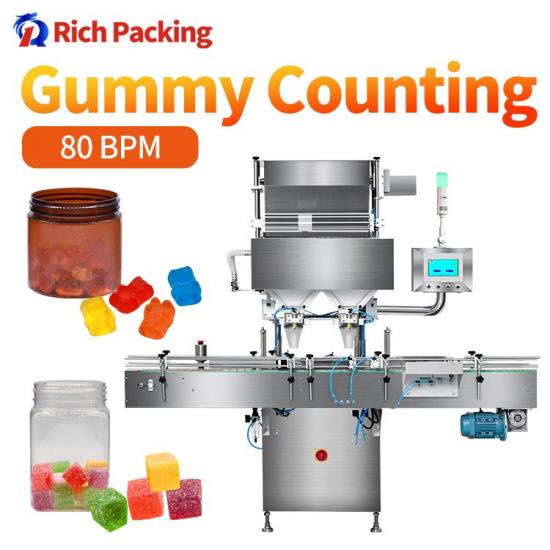

DSL Counting Gummy Bottling Machine By Rich Packing

automatic counting bottling machine for gummies by Our RICH PACKING Guangdong is designed for those foods with a sticky appearance specially. Specially for the solution of sticky gummies counting bottling bags which is popular in developed countries and developed regions, our group has obtained many patents and efficient planning solutions, including the most representative pectin edible gummies, rainbow candies in various colors, the Oil-coated gummy candies, and etc.

Many advantages of our company RICH PACKING Guangdong for candy counting counter solutions:

The machine has a built-in intelligent operating inspection system, and the running efficiency and accuracy of counting bottling have been improved greatly;

Equipped with a cylinder-specific equipment in hopper for dispersing gummies materials, so that before entering the vibration channel the candies will not stick together, that improves the production efficiency in it;

The other ordinary counting machines only use SUS 304 stainless steel in the vibration tank, but our company’s vibration tank is sprayed with Teflon material, which makes the movement of the candy smoothly.

Made by PTFE material, the blanking buckle is widened without any congestion, and meets the requirements of CGMP standards;

The above points are the main features of the upgrade of candy gummies counting machine. These help customers reduce their dependence on labor and save costs greatly. It saves time and effort in counting, and at the same time, it is connected and accurate in counting closely. It is can be sensitive to adjust kinds shapes, sizes and the textures of candy products to meet a variety of packaging methods.

*** Technical parameter

|

Model |

RQ-DSL-16R |

|

vibration groove tracks |

16 lane |

|

Production capacity |

200,000 ~ 360,000 grains/h |

|

accuracy rate |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

Applicable target |

Tablet:Φ3~25 mm ,pill:Φ3~20 mm, |

|

Applicable bottle type |

Φ25~75 mm round and square bottle, height ≤240 mm |

|

voltage |

AC380V 3P 50 / 60HZ |

|

power |

2.2 KW |

|

pressure |

0.4~ 0.6 Mpa |

|

Air consumption |

120 L/min |

|

Hopper capacity |

45 L |

|

weight |

650 kg |

|

Outline dim.(mm) |

1200×1550×1750 mm |

*** Configuration List

|

No. |

Item |

Specification |

Qty. |

Manufacturer |

|

1 |

Count Photoelectric Sensor (Receive) |

N24.5R |

16 |

Lattine |

|

2 |

Count Photoelectric Sensor (Emit) |

N24.5E |

16 |

Lattine |

|

3 |

Valve Group |

M4SB10-M5-6 |

2 |

Japan CKD |

|

4 |

Filtrate Regulator |

FR500 |

1 |

Taiwan SHAKO |

|

5 |

PLC Group |

FP∑-C32TH FPO-E16YT |

1 |

Japan Panasonic |

|

6 |

Touch Screen |

GE4408W |

1 |

Japan Pro-face |

|

7 |

Cable Diffuse Sensor |

QS18VN6DB |

3 |

USA.BANNER |

|

8 |

AC Contactor |

GMC-9 |

1 |

Korea LG |

|

9 |

DC Contactor |

GMD-9 |

3 |

Korea LG |

|

10 |

Thermal Overlood Relay |

GTH-22/3 |

1 |

Korea LG |

|

11 |

Count Cylinder |

SCPS2-1030 |

16 |

Japan CKD |

|

12 |

Position Cylinder |

SDA20-10 |

4 |

AIRTAC |

|

13 |

Control Box |

131200000 |

1 |

Germany MECANO |

|

14 |

Directive Signal Light |

AL6M-P |

3 |

Japan IDEC |

|

15 |

Button Switch |

ABW310EG |

1 |

Japan IDEC |

IPv6 network supported

IPv6 network supported